Blog

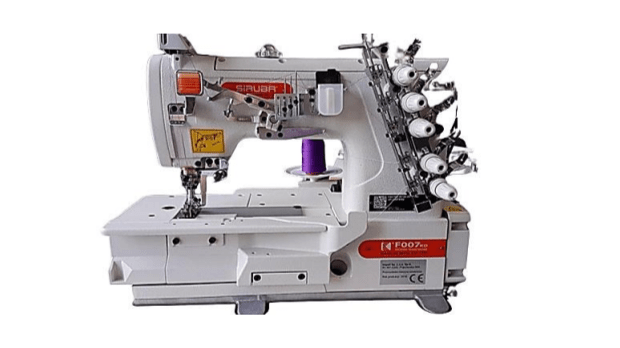

DETAILED INFORMATION ABOUT DOUBLE CHAIN STITCH MACHINE

15 Minute read

LET READ !

The double chain stitch sewing machine has a rich history

that dates back to the early 19th century.

It was invented by the French tailor,

Thimonnier, in 1830.

Thimonnier’s machine was a significant

breakthrough in the world of sewing, as it could

produce a continuous series of interconnected

loops, creating a strong and flexible stitch.

The invention of the chain stitch sewing

machine revolutionized the garment industry.

Before its advent, all sewing was done by

hand, which was a slow and labor-intensive process.

The chain stitch sewing machine marked the

beginning of automation in the textile industry,

significantly increasing the efficiency of garment

production.

A chain stitch machine is a type of sewing

machine that uses a single thread to create a strong

and flexible chain-like stitch, suitable for heavy

fabrics and stretchy applications.

It is a versatile and efficient machine, but

may require more skill to operate and maintain

than other machines.

FEATURES

Important features that make a double chain stitch sewing

machine different:

- Single thread: Uses only one thread to create a

chain-like stitch, making it strong and flexible. - High-speed stitching: Capable of fast stitching

speeds, making it efficient for large-scale

production. - Strong and flexible stitch : Creates a sturdy and

elastic stitch suitable for heavy fabrics and

stretchy applications. - Needle or 2-Needle options

- Flatbed design

- Bottom feed transport

- Built-in energy-saving motor

- Low vibration and noise level

- LED lighting of sewing area

- Semi-Dry Head with grease lubrication

- DLC needle bar (Carbon)

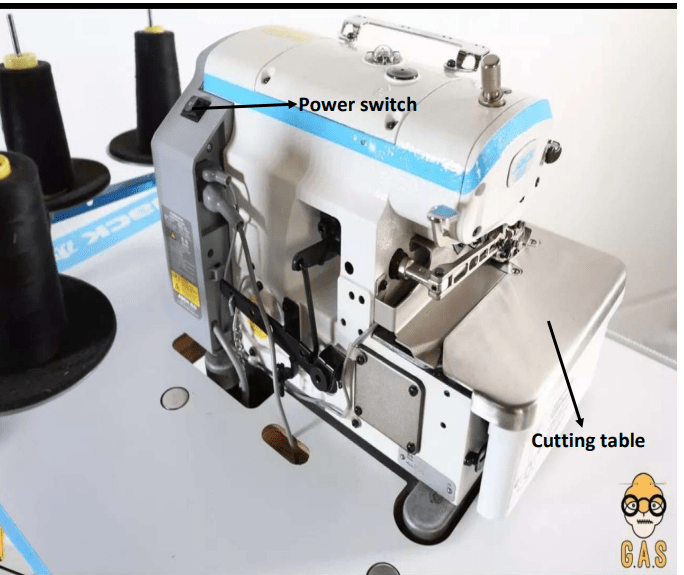

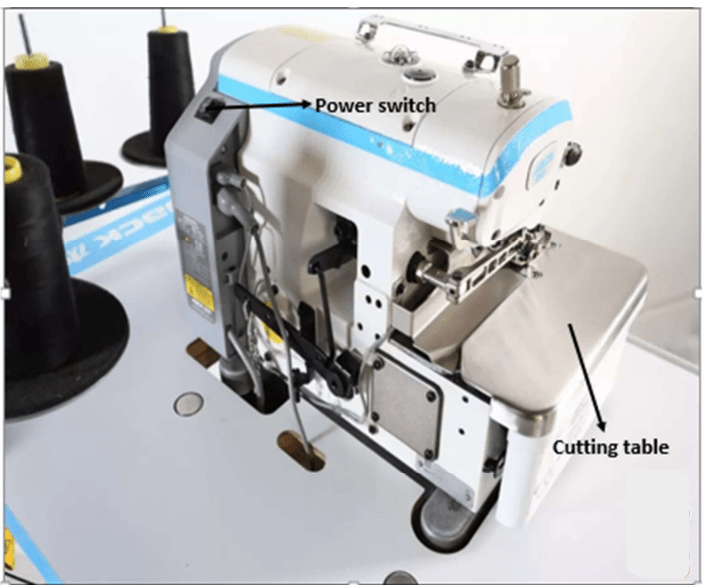

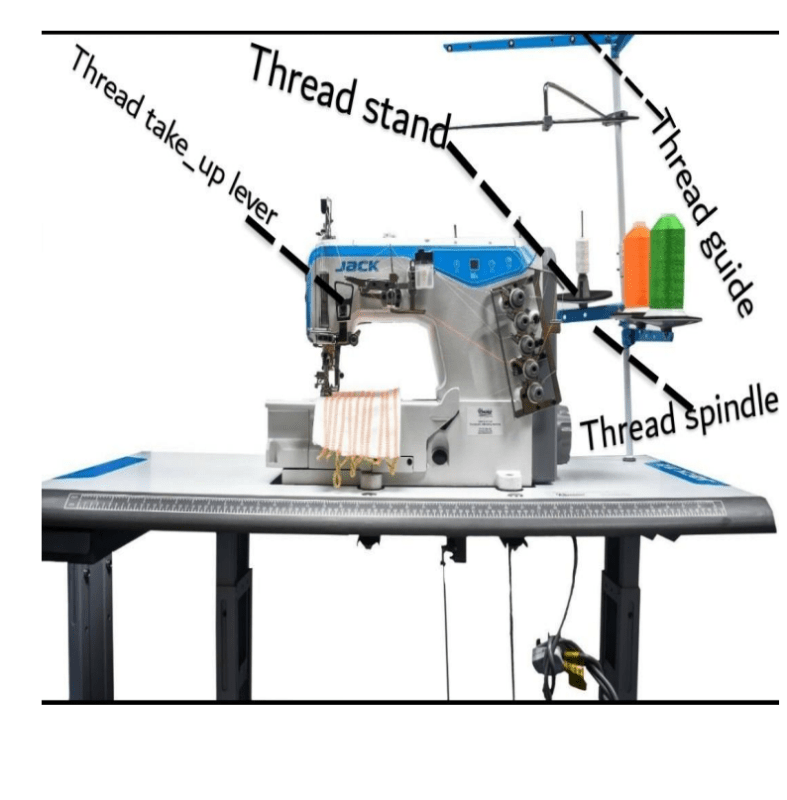

PROCESSES INVOLVED IN USING A JACK DOUBLE CHAIN

STITCH SEWING MACHINE:

- THREADING: Thread the machine with a single

thread, following the manufacturer’s

guidelines. - Setting stitch length: Adjust the stitch length to

suit the fabric and application. - Selecting fabric: Choose the fabric to be sewn,

ensuring it is suitable for chain stitch. - Placing fabric under presser foot : Position the

fabric under the presser foot, aligning the edge

with the guide. - Starting the machine: Turn on the machine and

begin sewing, slowly and steadily. - Guiding the fabric: Use the feed dog to guide

the fabric smoothly and consistently. - Sewing: Continue sewing, maintaining a steady

pace, until the desired length is achieved. - Backstitching: Reinforce the stitches by sewing

in reverse at the beginning and end. - Cutting thread: Cut the thread, leaving a small

tail.

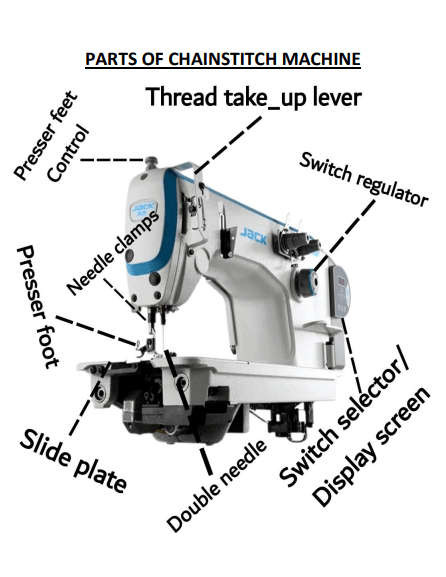

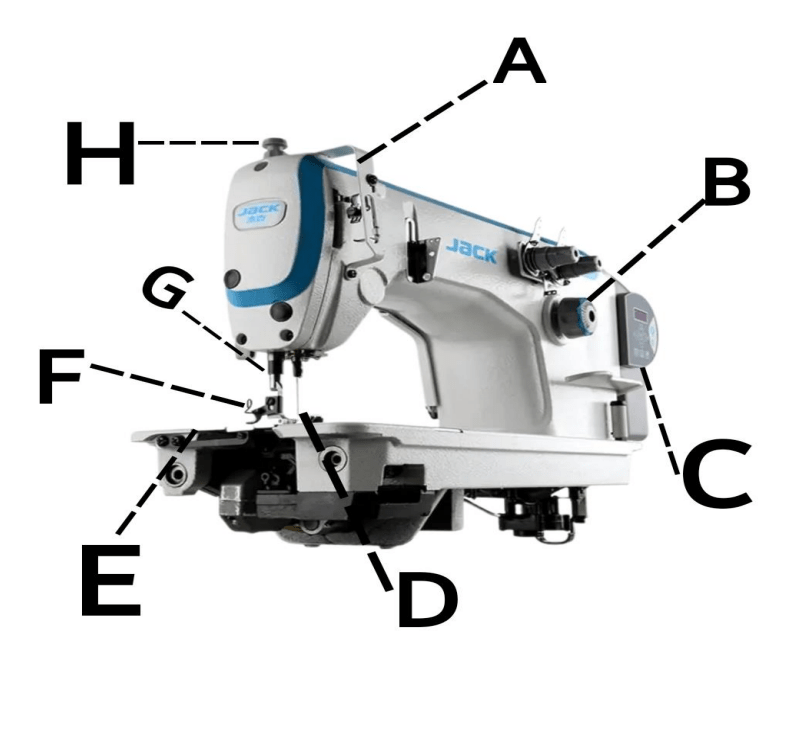

FUNCTIONS OF EACH PART

- Thread Take-Up Lever is a mechanism that

pulls the thread up and away from the needle,

creating a consistent and even stitch length,

and helping to prevent thread bunching and

tangling

2.A Switch Regulator is a component in a sewing

machine that controls the amount of thread

that is released from the spool, regulating the

tension of the thread and ensuring a consistent

stitch quality.

In essence, the Switch Regulator acts

as a “traffic cop” for the thread, ensuring that

the right amount of thread is released at the

right time, resulting in a professional-looking

stitch.

3.A Switch Selector or Display Screen is a control

panel on a sewing machine that allows the user

to select various stitch options, settings, and

features, and displays the chosen settings and

information, making it easy to navigate and

customize the sewing process.

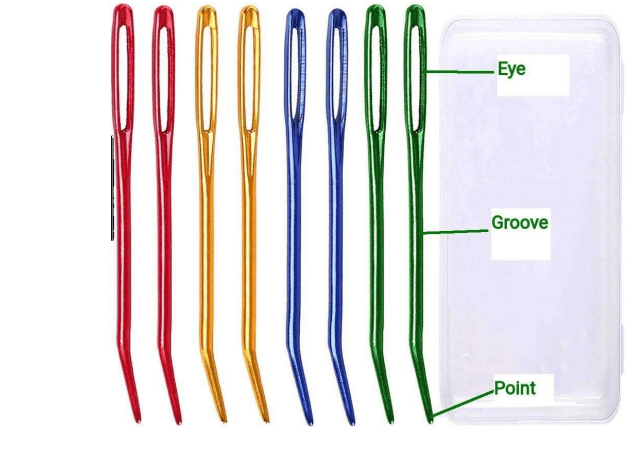

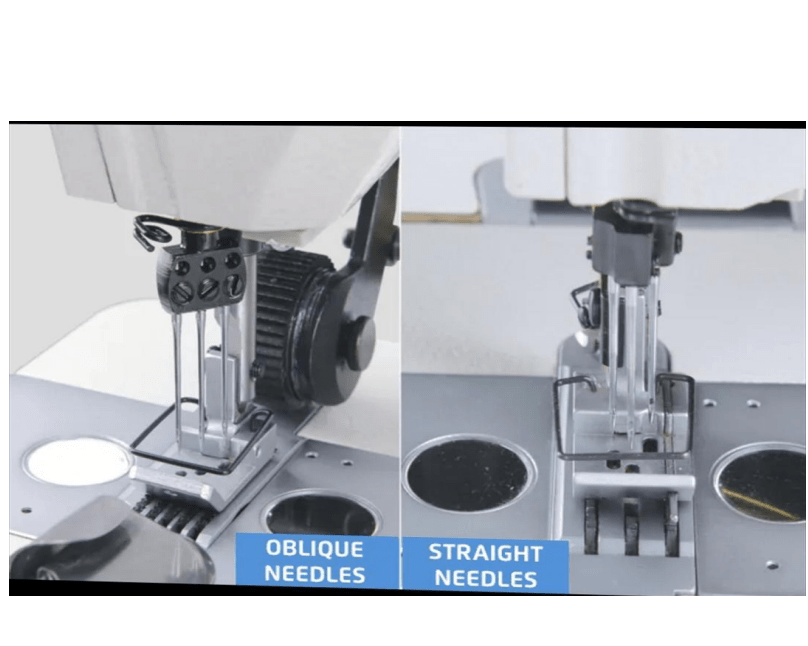

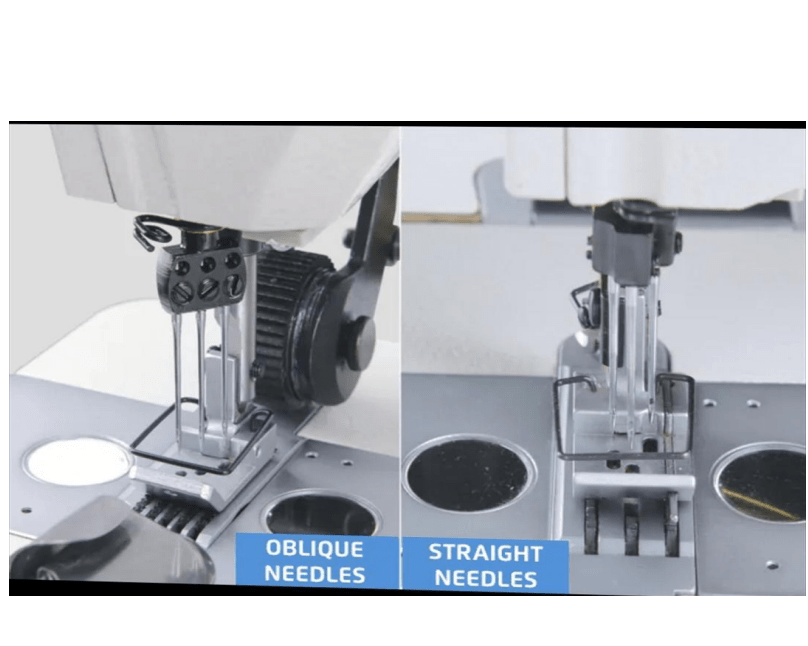

4.A Double Needle is also commonly known as a

“Twin Needle” or “Double Pitch Needle”. A

Double Needle is a specialized sewing machine

needle that has two parallel needles mounted

together, allowing for the simultaneous sewing

of two parallel rows of stitches, typically used

for sewing heavy fabrics, creating a strong and

durable seam, and adding a decorative touch to

garments and home decor items. Two Needle

Positions

It is possible to set the high and low needle

position from the digital display.

5.A Slide Plate,: also known as a Slide Presser

Foot or Slide Feed Dog, is a mechanism on a

sewing machine that allows for smooth and

easy movement of the fabric being sewn, by

sliding the presser foot or feed dog along a

track or groove, enabling effortless feeding of

the fabric and consistent stitching.

6.Presser feet; on a double chain stitch machine guide

and control the fabric, ensuring consistent and

precise stitching, and facilitating smooth fabric

feeding and decorative stitching capabilities.

7.The Needle Clamps (or Needle Cramps) of a double

chain stitch sewing machine hold the needle

firmly in place, enabling precise control and

consistent stitch quality.

8.Presser feet control refers to the mechanism

that regulates the pressure and movement of

the presser foot on a sewing machine, allowing

the user to adjust the amount of pressure

exerted on the fabric and control the fabric’s

movement under the needle.

USES/BENEFIT OF DOUBLE CHAIN STITCH SEWING

MACHINE

Chain stitch machines have several uses and

benefits, including:

- Sewing heavy fabrics: Chain stitch

machines are ideal for sewing thick, heavy, or

dense fabrics like denim, canvas, and leather. - Reinforcing seams: Chain stitch machines

create strong, durable seams, making them

perfect for reinforcing stress points on

garments, bags, and home decor items. - Decorative stitching: Chain stitch machines

can create decorative stitches, such as

embroidery, topstitching, and edging. - Quick sewing: Chain stitch machines are fast

and efficient, making them ideal for large-scale

sewing projects, like sewing curtains,

upholstery, and canvas tarps. - Industrial applications: Chain stitch machines

are widely used in industries like textile, leather,

and manufacturing for heavy-duty sewing tasks. - Repair work: Chain stitch machines are great

for repair work, like fixing torn seams,

reattaching buttons, and mending holes. - Crafting: Chain stitch machines are used in

various crafts, such as quilting, embroidery, and

home decor projects. - Consistency: Chain stitch machines produce

consistent, high-quality stitches, making them

perfect for production sewing.

MAINTENANCE MEASURES FOR THE 1-NEEDLE,

FLATBED CHAIN STITCH DOUBLE CHAIN STITCH

SEWING MACHINE:

- Regular Cleaning:

- Clean the machine’s head, needle area, and

surrounding parts regularly with a soft brush

and dry cloth. - Remove any debris, dust, or thread ends.

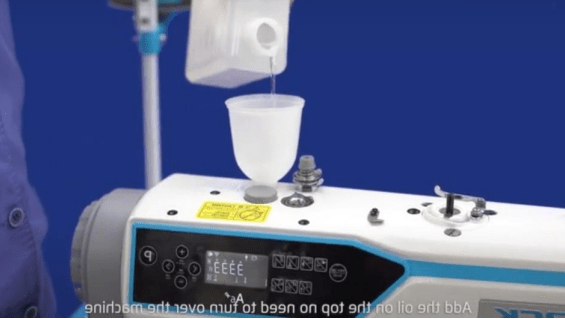

2. Lubrication:

- Apply grease to the machine’s moving parts,

such as the needle bar, feed dog, and presser

foot. - Use the recommended type and amount of

grease to avoid excessive lubricant buildup.

3. Needle Maintenance:

- Regularly inspect and replace worn or

damaged needles. - Use the correct needle type and size for the

specific fabric and stitch type.

4. Thread Management:

- Regularly clean and inspect the thread take up lever and tension discs.

- Ensure proper thread tension to prevent

thread breaks and knots.

5. Feed Dog Maintenance:

- Regularly clean and inspect the feed dog

and its surrounding area. - Ensure proper feed dog alignment and

adjustment.

6. Presser Foot Maintenance:

- Regularly clean and inspect the presser foot

and its surrounding area. - Ensure proper presser foot alignment and

adjustment.

7. Motor Maintenance:

- Regularly inspect and replace worn or

damaged belts. - Use the recommended type and size of belt.

- Belt Replacement:

- Regularly inspect and replace worn or

damaged belts. - Use the recommended type and size of belt.

9. Screw and Bolt Tightening:

- Regularly inspect and tighten any loose

screws and bolts. o - Ensure proper tightening to prevent

machine vibration and noise.

- Manufacturer’s Guidelines:

- Follow the manufacturer’s recommended

maintenance schedule and guidelines. - Refer to the user manual and maintenance

manual for specific instructions.

By following these maintenance measures, you

can ensure optimal machine performance,

prevent breakdowns, and extend the machine’s

lifespan.

SAFETY MEASURES FOR THE 1-NEEDLE,

FLATBED CHAIN STITCH, DOUBLE CHAIN STITCH

SEWING MACHINE:

- Personal Protective Equipment:

- Wear protective gloves to prevent hand

injuries. - Wear safety glasses or goggles to prevent

eye injuries. - Wear a dust mask to prevent inhalation of

thread and fabric particles.

2. Machine Guarding:

- Ensure all machine guards are in place and

functioning properly. - Never remove or tamper with machine

guards.

3. Proper Training:

- Ensure proper training and experience

before operating the machine. - Read and understand the user manual and

safety guidelines.

4. Work Area Safety:

- Keep the work area clean, well-lit, and free

of clutter. - Ensure good ventilation to prevent

inhalation of thread and fabric particles.

5. Electrical Safety:

- Ensure the machine is properly grounded

and plugged into a grounded outlet. - Avoid overloading the machine with

excessive fabric or thread.

6. Machine Maintenance:

- Regularly inspect and maintain the machine

to prevent mechanical failures. - Follow the manufacturer’s recommended

maintenance schedule.

7. Emergency Stop

- Ensure easy access to the emergency stop

button or switch. - Know how to properly stop the machine in

case of an emergency.

8. Fire Prevention:

- Keep a fire extinguisher nearby.

- Ensure proper disposal of thread and fabric

scraps to prevent fires.

9. Ergonomic Safety:

- Ensure proper seating and posture while

operating the machine. - Take regular breaks to prevent fatigue and

musculoskeletal disorders.

10. Manufacturer’s Guidelines:

- Follow the manufacturer’s recommended

safety guidelines and precautions.

QUESTIONS

Using the diagram below answer question 1_10

by naming the components labeled (A) to (H)

1)The components labeled A is known as____________

A)Thread take_up lever

B)Presser feet

C)Switch Regulator

D) Slide Plate

2)The component labeled C is known as

A)Switch selector

B)Display screen

C) All of the above

D) None

3)The component labeled as B is known

as_______________

A)SWITCH REGULATOR

B)Switch selector

C)Slide plate

D) Needle cramps

4)The components labeled as D is known

as____________________

A)Double Needle

B)Presser foot

C)Thread take_up lever

D) Presser feet control

5)The component labeled as E is known as__________

A)Presser foot

B)Slide Plate

C)Needle cramps

D) Switch Regulator

6)The component labeled as F is known as___________

A)Control switch

B)Spool pin

C)Needle Cramps

D) Presser feet

7)The component labeled as G is known as__________

A)Pressure

B)Energy loom

C)Needle Cramps

D) Clamps

8)The components labeled as H is known as_________

A)Presser feet control

B)Pressure feet control

C)Control switch

D) Switch Regulator

PARTS B

Choose the correct answer from the options

9)Who invented the chain stitch sewing

machine in 1830?___________

A) Thimonnier

B) Elias Howe

C) Isaac Singer

D) Allen B. Wilson

10) What was the significant breakthrough

of Thimonnier’s machine?_________

A) It could produce a continuous series of

interconnected loops

B) It could sew only straight line

C) It could sew only curved lines

D) It could sew only heavy fabrics

11) What was the impact of the chain stitch

sewing machine on the garment industry?

A) It decreased efficiency

B) It increased efficiency

C) It had no impact

D) It made sewing machines obsolete

12) What type of sewing was done before

the advent of the chain stitch sewing

machine?__________

A) Machine sewing

B) Hand sewing

C) Automated sewing

D) Computerized sewing

13) What is a characteristic of the stitch

produced by a chain stitch sewing machine?

A) Strong and flexible

B) Weak and brittle

C) Rigid and inflexible

D) Loose and uneven

14)What is a feature of a chain stitch sewing

machine?____________

A) Uses multiple threads

B) Uses a single thread

C) Can only sew straight lines

D) Can only sew curved lines

15)What is an advantage of a chain stitch

sewing machine?_________

A) It is slow and labor-intensive

B) It is efficient for large-scale production

C) It is only suitable for light fabrics

D) It is difficult to operate and maintain

16) What type of fabrics is a chain stitch

sewing machine suitable for?_

A) Heavy and stretchy fabrics

B) Light and delicate fabrics

C) Only cotton fabrics

D) Only silk fabrics

17)How many threads does a chain stitch

sewing machine use?__________

A) Multiple threads

B) A single thread

C) Two threads

D) Three threads

18)What is a benefit of using a chain stitch

sewing machine?________

A) It increases production time

B) It decreases production time

C) It has no impact on production time

D) It is not suitable for production

- What does the Thread Take-Up Lever

do?_________

A) Regulates thread tension

B) Pulls thread up and away from needle

C) Cuts excess thread

D) None of the above - What does the Switch Regulator

control?___________

A) Thread tension

B) Fabric movement

C) Needle position

D) Stitch length - What is the purpose of the Switch

Selector?_____

A) To select stitch options

B) To regulate thread tension

C) To control fabric movement

D) To adjust needle position - What is the advantage of using a Double

Needle?________

A) Sewing heavy fabrics

B) Creating decorative stitches

C) Reducing thread tension

D) All of the above - What does the Slide Plate

enable?_________

A) Smooth fabric movement

B) Consistent thread tension

C) Easy needle threading

D) None of the above - What do Presser feet guide?__________

A) Fabric and stitching

B) Thread and needle

C) Fabric only

D) Stitching only - What do Needle Clamps hold?__________

A) Thread in place

B) Needle firmly

C) Fabric in place

D) None of the above - What does Presser feet control

regulate?___________

A) Pressure and movement

B) Thread tension and stitch length

C) Fabric movement and needle position

D) None of the above - What is the result of Switch Regulator?

A) Consistent stitch quality

B) Professional-looking stitch

C) Reduced thread tension

D) All of the above - What is Double Needle suitable for?___________

A Heavy fabrics

B) Delicate fabrics

C) Stretchy fabrics

D) All of the above - What does Slide Plate

facilitate?__________

A) Effortless feeding

B) Consistent stitching

C) Easy threading

D) None of the above - What do Presser feet facilitate besides

consistent stitching?_________

A) Decorative stitching capabilities

B) Easy fabric movement

C) Reduced thread tension

D) None of the above

PARTS C

Fill in the gap from 31_50

- How often should the machine be

cleaned? – ___________ - What type of lubricant should be

used on moving parts? ____________

- How often should needles be

replaced? – ___________ - What should be done to prevent

thread breaks? ____________

- How often should feed dogs be

inspected? ____________

- What should be done to prevent

motor overheating? __________

- How often should belts be replaced?

- ___________

- What should be done to prevent

machine vibration? __________

- What type of fabrics are chain stitch

machines ideal for sewing? ___________

40 . What is a benefit of using chain

stitch machines for seams? _________

- What should be worn to prevent

hand injuries? ___________

- What should be worn to prevent eye

injuries? – ___________ - What should be done to prevent

machine guarding failures? ____________

- What should be done to prevent

electrical shocks? ________

- How often should the work area be

cleaned? – ___________ - What should be done to prevent

fires? – ___________ - What should be done in case of an

emergency? ___________

- What should be done to prevent

musculoskeletal disorders? __________

- What type of stitching can chain

stitch machines create? ___________

- What is an advantage of using chain

stitch machines for large-scale sewing

projects? – ___________

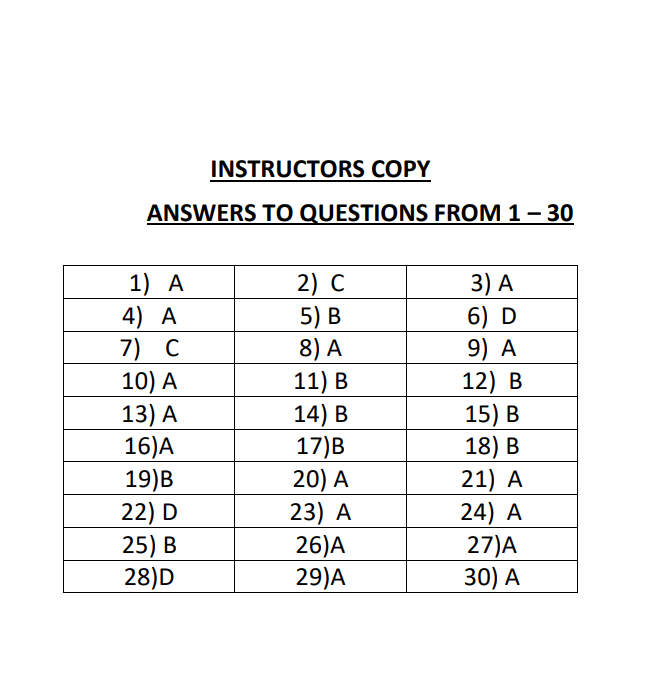

ANSWERS TO QUESTIONS FROM 31 TO

50

31.Regularly

39. Thick, heavy, or dense fabrics

32.Grease

33.Often

34.Adjust

35.Regularly

36.Ventilate

37.Regularly

38.Tighten

40. Strong, durable seams

41.Gloves

42.Goggles

43.Inspect

44.Ground

45. Daily

46.Extinguish

47.Stop

48.Stretch

49. Decorative stitches (such as embroidery,

topstitching, and edging)

50.Fast and efficient sewing