21 minute read

Definition

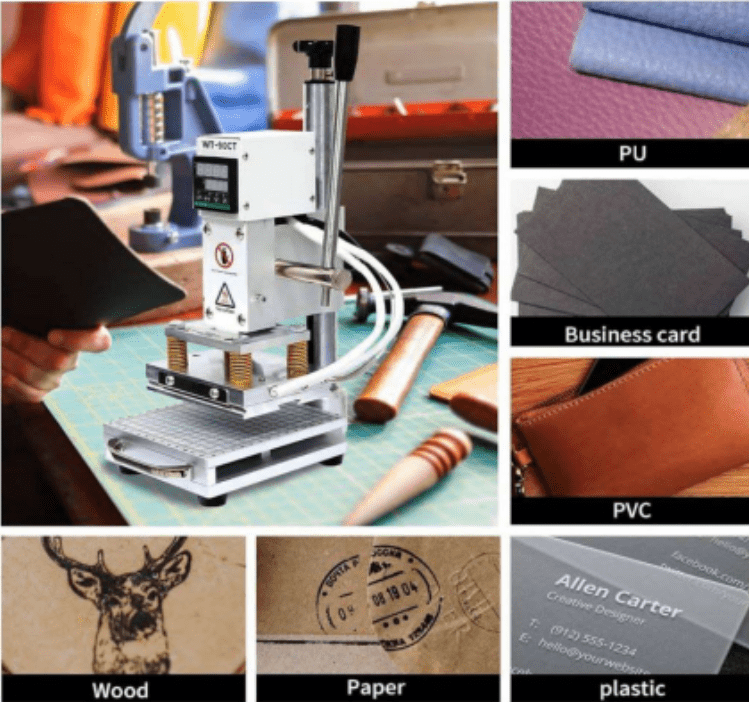

A sublimation printer is a type of inkjet printer

that uses heat to transfer dye onto materials such as

ceramics, glass, metal, and polyester fabrics. It is a

specialized inkjet printer designed for printing

vibrant, full-color images onto various materials.

History of the sublimation printer

The concept of sublimation printing was first

discovered by French physicist Marc Gregoire, in the

year 1950 who experimented with the sublimation

process of solid dyes.

The first sublimation printers were developed in

the year 1960, using a process called “dye diffusion

thermal transfer.” These early printers were used

primarily for printing images onto ceramics and glass.

The introduction of inkjet technology

revolutionized sublimation printing in the year 1980,

making it more accessible and affordable for small

businesses and hobbyists.

In the year 1990, the development of digital

sublimation printers enabled users to print high quality images directly from computers, expanding

the possibilities for custom printing.

Advancements in ink and paper technology led to

improved image quality, durability, and color

vibrancy in the 2000s

Present day: Sublimation printers are widely used

in various industries, including:

1.Personalized gifts and promotional products

2.Signage and displays

3.Fashion and apparel

4.Home decor and furnishings

5.Fine art and photography

Throughout its history, sublimation printing has

evolved from a niche technology to a versatile and

popular method for creating custom prints on various

materials. Today, sublimation printers are used by

artists, small businesses, and large corporations alike,

offering a unique and creative way to produce high quality images and products.

Uses Of a Sublimation Printer

- Custom phone cases: Print vibrant designs and

photos onto phone cases for a personalized touch. - Personalized mugs: Create unique and colorful

mugs for gifts or personal use. - Photo prints on metal: Turn your favorite photos

into stunning metal prints for a modern display. - Custom clothing: Print designs, logos, or images

onto polyester fabrics for custom t-shirts, hoodies,

and more. - Signage and displays: Create eye-catching signs,

banners, and displays for events, businesses, or

exhibitions. - Custom water bottles: Design and print

personalized water bottles for a stylish and functional

accessory. - Home decor: Print images onto ceramic tiles,

coasters, or other home decor items for a

personalized touch. - Gaming accessories: Create custom designs for

gaming controllers, console skins, and other

accessories. - Promotional products: Print logos, designs, or

messages onto various materials for promotional

items like mousepads, keychains, and more. - Artistic expressions: Use sublimation printing to

create unique and vibrant art pieces, such as abstract

designs or photographic prints on metal or glass.

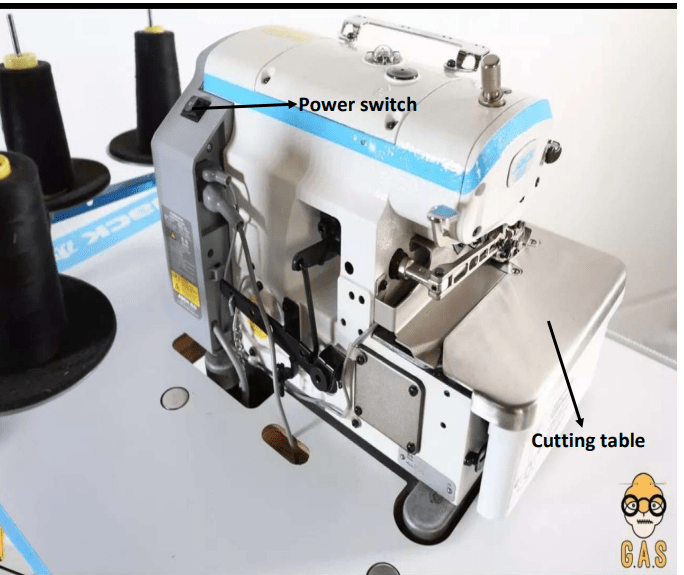

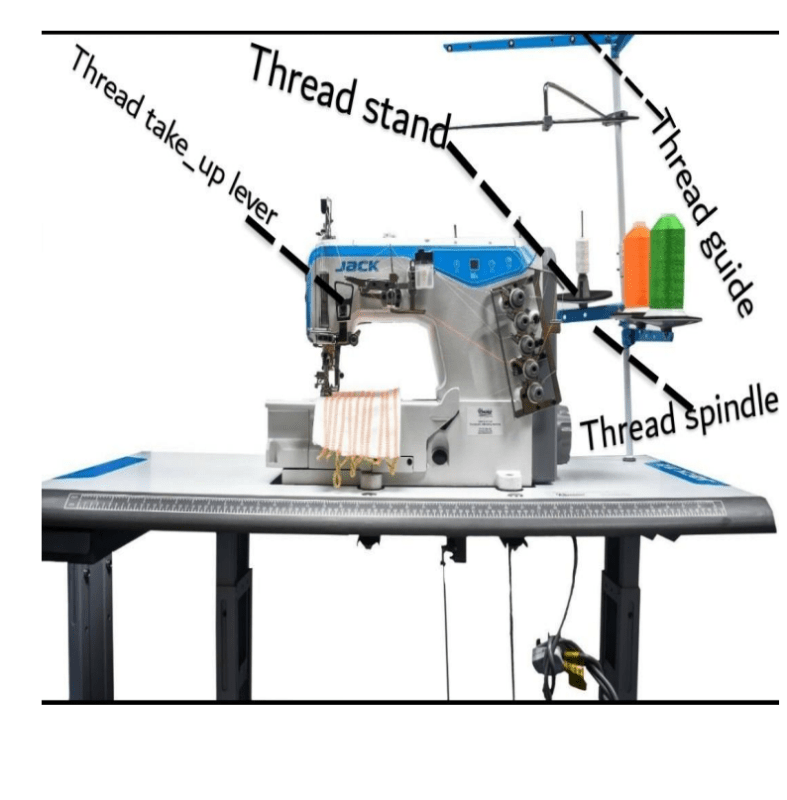

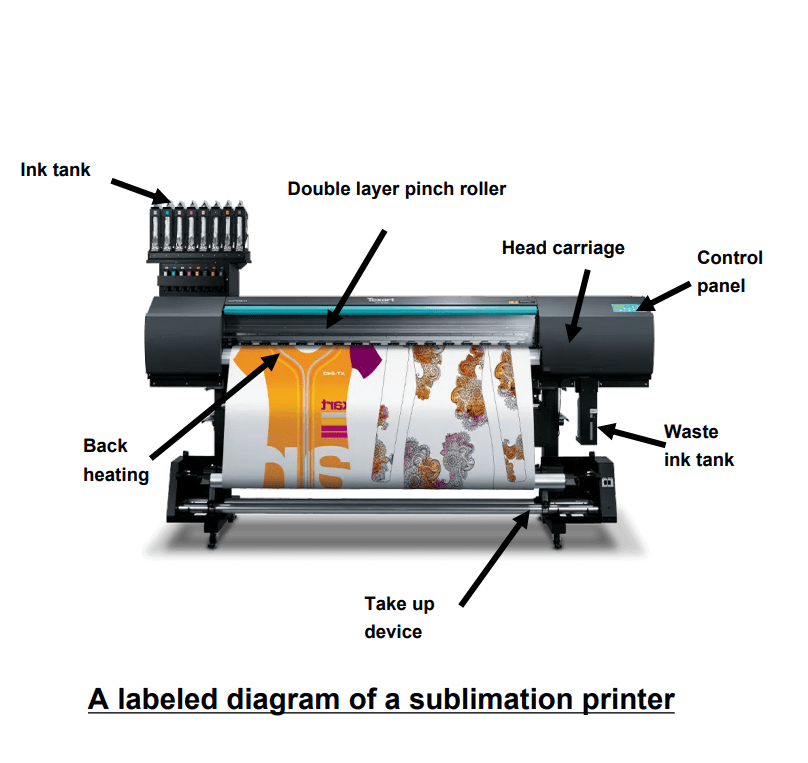

Explanation of the labeled parts above

- Ink Tank: Holds the sublimation ink that’s used

for printing. The ink tank is typically removable and

replaceable when empty. - Double Layer Pinch Roller: A mechanism that

grips and feeds the sublimation paper through the

printer. The double layer design ensures precise

control and prevents paper jamming. - Head Carriage: The moving carriage that holds

the print head, which deposits the ink onto the paper.

The head carriage moves back and forth to print the

image. - Control Panel: The interface that allows users to

operate the printer, adjust settings, and monitor the

printing process. - Back Heating: A heating element located at the

back of the printer that pre-heats the sublimation

paper before printing. This helps to ensure even ink

transfer and prevents paper curling. - Waste Tank: A container that collects the excess

ink and waste material generated during the printing

process. - Take-Up Device: A mechanism that winds up the

printed paper or media after it’s been printed. This

keeps the paper tidy and organized and can also help

to prevent paper curling

Benefits Of a Sublimation Printer

1.Speed and Efficiency: Sewing machines can

sew much faster than sewing by hand, which

makes them ideal for large projects or projects

with a deadline.

2.Precision and Accuracy: Sewing machines can

sew in a straight line, which makes them ideal

for sewing projects that require straight seams.

3.Versatility in Stitching: Sewing machines can

sew a variety of stitches, which makes them

ideal for sewing projects that require different

types of stitches.

4.Professional-looking results: Sewing machines

can produce professional-looking results, which

makes them ideal for sewing projects that require

a high level of quality.

5.Automated sewing: Sewing machines can

automate the sewing process, which makes them

ideal for sewing projects that require a lot of

repetition.

6.Easy to use: Sewing machines are relatively

easy to use, which makes them ideal for sewing

projects that require a lot of sewing.

7.Consistent stitches: Sewing machines can

produce consistent stitches, which makes them

ideal for sewing projects that require a high level

of quality.

8.Saves time: Sewing machines can save time,

which makes them ideal for sewing projects that

require a lot of sewing.

9.Increases productivity: Sewing machines can

increase productivity, which makes them ideal

for sewing projects that require a lot of sewing.

- Cost-effective: Sewing machines can be

cost-effective, which makes them ideal for

sewing projects that require a lot of sewing.

Safety Precaution To Take When Using The

Sublimation Printer

When operating a sublimation printer, it’s important

to take the following safety precautions:

- Read the manual: Familiarize yourself with the

printer’s instructions and guidelines. - Wear protective gear: Use gloves, safety glasses,

and a mask when handling ink and paper. - Work in a well-ventilated area: Avoid inhaling

sublimation ink fumes and particles. - Keep children and pets away: Sublimation printers

can be hazardous for children and pets. - Use the printer on a stable surface: Ensure the

printer is placed on a level, stable surface. - Avoid overheating: Keep the printer away from

direct sunlight and heat sources. - Handle paper carefully: Avoid touching or

handling paper excessively, as oils from skin can

affect print quality. - Use proper electrical connections: Ensure the

printer is connected to a suitable power source and

avoid overloading outlets. - Regularly clean the printer: Prevent dust and

debris build up to avoid fires or electrical issues. - Follow ink handling guidelines: Handle

sublimation ink according to the manufacturer’s

instructions. - Avoid ingesting sublimation materials: Keep ink,

paper, and other materials out of reach of children

and pets. - Use a fire extinguisher nearby: Have a fire

extinguisher nearby in case of emergencies. - Keep long hair and loose clothing tied back:

Avoid accidents caused by hair or clothing getting

caught in the printer. - Avoid wearing jewelry: Jewelry can get caught in

the printer or cause electrical issues. - Take regular breaks: Take breaks every hour to

stretch and rest your eyes.

Remember to always follow the manufacturer’s

specific guidelines and safety recommendations for

your sublimation printer model.

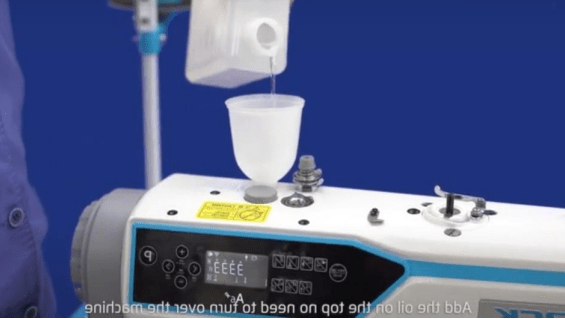

How to maintain a sublimation printer

- Regularly clean the print head: Use lint-free cloth

and water to remove dust and debris. - Check and replace ink cartridges: Monitor ink

levels and replace cartridges when necessary. - Clean the printer rollers: Use soft cloth and water

to remove dust and debris. - Align the print head: Follow the manufacturer’s

instructions to ensure proper alignment. - Update printer software: Regularly update the

printer’s software to ensure optimal performance. - Use genuine sublimation ink: Avoid using generic

ink to maintain print quality and prevent damage. - Clean the printer’s interior: Use a soft brush and

vacuum to remove dust and debris. - Check and replace the print head: Replace the print

head every 6-12 months or as recommended by the

manufacturer. - Use a humidity-controlled environment: Store the

printer in a room with a stable humidity level (40-

60%). - Perform regular nozzle checks: Run the printer’s

built-in nozzle check to identify and fix any clogged

nozzles.

Additional tips:

1.Handle sublimation paper carefully to avoid

scratches and damage.

2.Use a paper dust cover to prevent dust from

accumulating on the paper.

3.Avoid exposing the printer to direct sunlight and

extreme temperatures.

4.Turn off the printer when not in use to conserve

energy and extend its lifespan.

By following these maintenance tips, you can extend

the life of your sublimation printer, ensure optimal

performance, and produce high-quality prints.

Summary

A sublimation printer is a type of inkjet printer that

uses heat to transfer dye onto materials such as

ceramics, glass, metal, and polyester fabrics. Here’s a

summary:

Key Features:

1.Uses sublimation ink and heat to create

permanent, full-color images

2.Compatible with various materials, including

ceramics, glass, metal, and polyester fabrics

3.High-resolution printing (up to 1440 dpi)

4.Compact design for small spaces

5.Easy to use and maintain.

Benefits:

1.Permanent, long-lasting prints

2.Vibrant colors and detailed images

3.Durable and resistant to fading, scratches, and

moisture

4.Cost-effective for small to medium-sized print

runs

5.Versatile for various applications (gifts, signage,

clothing, etc.).

Common Uses:

1.Custom phone cases and laptop skins

2.Personalized mugs, water bottles, and drinkware

3.Photo prints on metal, glass, and wood

4.Custom clothing, accessories, and home decor

5.Signage, displays, and promotional products

Maintenance:

1.Regularly clean the print head and printer rollers

2.Check and replace ink cartridges and print heads

3.Update printer software and use genuine

sublimation ink

4.Clean the printer’s interior and handle paper

carefully

Safety Precautions:

1.Read the manual and follow guidelines

2.Wear protective gear and work in a well ventilated area

3.Keep children and pets away and handle paper

carefully

4.Avoid overheating and electrical issues

Overall, sublimation printers offer a unique and

creative way to produce high-quality images and

products, making them a popular choice for various

applications.

Multi choice Questions.

Part A

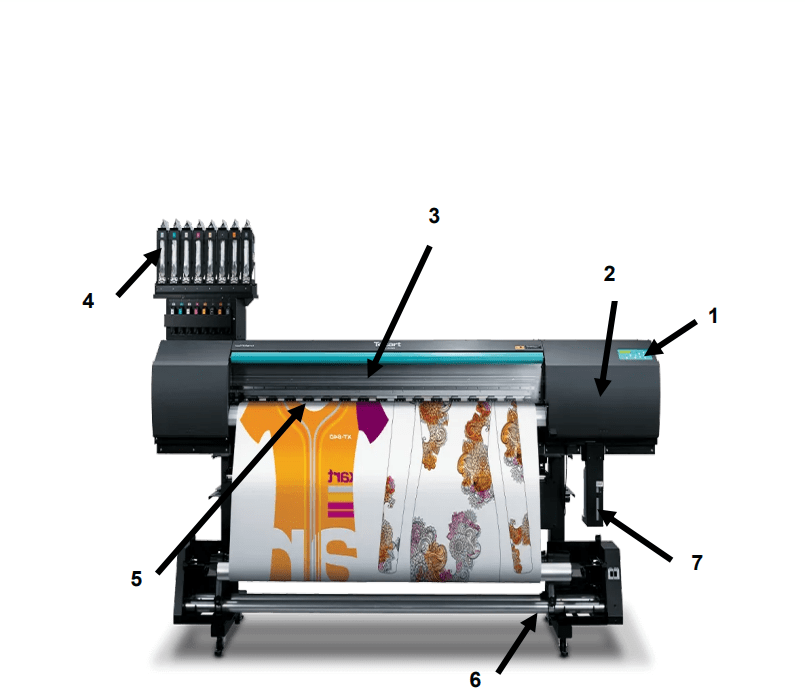

From the diagram below choose the correct option

that matches the number.

1) The labeled part 7 is called.

A. Printer

B. Waste ink tank

C. Back heating

D. Printer back

2) The labeled part 5 is called.

A. Back heating

B. Ink tank

C. Waste printer

D. Head base

3) The labelled part 1 is called.

A. Back heater

B. Ink tank

C. Double layer

D. Control panel

4) The labelled part 4 is called.

A. Head carriage

B. Layer pinch

C. Double roller

D. Ink tank

5) The labelled part 2 is called.

A. Printer base

B. Double layer panel

C. Head carriage

D. Ink tank

6) The labelled part 6 is called.

A. Take device up

B. Ink base

C. Take up device

D. Layer panel

7)The labelled part 3 is called?

A. Device panel

B. Double layer pinch roller

C. Control panel

D. Back heating

PART B

Pick the right option in each question

among the answer listed below

- What safety precautions should you take when

handling sublimation ink and paper?

A) Handle with bare hands and breathe in deeply to

appreciate the scent

B) Wear protective gloves and safety glasses to

prevent skin contact and eye irritation

C) Leave the ink and paper unattended near an open

flame

D) Mix the ink with water to create a homemade

cleaning solution - What should you do in case of an ink spill?

A) Wipe it up with a cloth

B) Use water to clean it up

C) Follow the manufacturer’s cleanup procedure

D) Leave it to dry on its own - How often should you clean the printer?

A) Daily

B) Weekly

C) Monthly

D) Rarely - What should you wear to protect yourself from

ink and paper dust?

A) A mask and gloves

B) Safety glasses and a hat

C) A dust mask and protective clothing

D) Nothing, it’s not necessary - Objective: How should you dispose of waste ink

and paper?

A) Recycle it

B) Throw it away in the trash

C) Pour it down the drain

D) Burn it - Objective: What should you do if you experience

eye irritation from the printer?

A) Rub your eyes

B) Flush them with water

C) Seek medical attention

D) Ignore it - How should you handle sublimation paper?

A) Touch it with your bare hands

B) Handle it carefully to avoid scratches

C) Crumple it up and throw it away

D) Use it as a napkin

15.What should you do if the printer overheats?

A) Keep printing to finish the job

B) Turn it off and let it cool down

C) Use a fan to cool it down

D) Call the manufacturer

16.How should you store sublimation ink and paper?

A) In a hot and humid environment

B) In a cool and dry place

C) In direct sunlight

D) Near an open flame - What should you do if you experience paper jam?

A) Force the paper through

B) Turn off the printer and carefully remove the

paper

C) Use a tool to pry it out

D) Call the manufacturer - How often should you check the printer’s

maintenance status?

A) Daily

B) Rarely

C) Monthly

D) Weekly - What is a key benefit of using a sublimation

printer for printing on ceramics and glass?

A) Faster printing speeds

B) Higher ink costs

C) Permanent, fade-resistant images

D) Limited color options - Which benefit does a sublimation printer offer for

printing on metal and wood?

A) Durable, scratch-resistant prints

B) High-quality, photorealistic images

C) Easy to use and maintain

D) Low-cost ink replacement - Which benefit does a sublimation printer offer for

small businesses and entrepreneurs?

A) High upfront costs

B) Cost-effective, on-demand printing

C) Limited product versatility

D) Complex operating requirements - Objective: What is a key benefit of using a

sublimation printer for artistic and creative projects?

A) Ability to print on various materials and

substrates

B) Inflexible printing materials

C) Limited color palette options

D) Slow printing speeds

- How often should you check the printer’s

maintenance status?

A) Daily

B) Rarely

C) Monthly

D) Weekly - What is a key benefit of using a sublimation

printer for printing on ceramics and glass?

A) Faster printing speeds

B) Higher ink costs

C) Permanent, fade-resistant images

D) Limited color options - Which benefit does a sublimation printer offer for

printing on metal and wood?

A) Durable, scratch-resistant prints

B) High-quality, photorealistic images

C) Easy to use and maintain

D) Low-cost ink replacement

21.What is the major advantage of using a

sublimation printer for custom phone case and laptop

skin production?

A) Quick turnaround times

B) High-volume production capabilities

C) Vibrant, full-color images with precise detail

D) Low-cost materials - Which benefit does a sublimation printer offer for

small businesses and entrepreneurs?

A) High upfront costs

B) Cost-effective, on-demand printing

C) Limited product versatility

D) Complex operating requirements - Objective: What is a key benefit of using a

sublimation printer for artistic and creative projects?

A) Ability to print on various materials and

substrates

B) Inflexible printing materials

C) Limited color palette options

D) Slow printing speeds

24) Sublimation Printer Transfers Dye on These

Materials Except?

A) Ceramic

B) Glass

C) Sand

D) Metals - What is the common use of sublimation printers

in the promotional products industry?

A) Printing on paper and fabric

B) Creating custom phone cases and laptop skins

C) Producing personalized mugs and water bottles

D) Making large-format banners and signs

Which industry uses sublimation printers to

create custom products for events and trade shows?

A) Healthcare

B) Retail

C) Hospitality

D) Events and Exhibitions - Which use of sublimation printers involves

printing on metal and wood materials?

A) Custom phone cases and laptop skins

B) Personalized mugs and water bottles

C) Photo prints and artwork

D) Signage and displays - What is the common use of sublimation printers

in the gifting industry?

A) Creating custom phone cases and laptop skins

B) Producing personalized mugs and water bottles

C) Making custom signage and displays

D) Producing personalized gifts and novelties

26. The First Sublimation Printer Was First

Developed in The Year?

A) 1970

B) 1950

C) 1960

D) 2010

27. The Development of Digital Sublimation Printers

Enables Users To?

A) Print High Quality Image

B) Record Videos

C) Copy High Quality Image

D) Read Quality Text

- What is the common use of sublimation printers

in the promotional products industry?

A) Printing on paper and fabric

B) Creating custom phone cases and laptop skins

C) Producing personalized mugs and water bottles

D) Making large-format banners and signs - Which industry uses sublimation printers to create

custom signage and displays?

A) Healthcare

B) Retail

C) Hospitality

D) Education - What is a popular use of sublimation printers in

the awards and recognition industry?

A) Creating custom plagues and trophies

B) Printing on glass and metal

C) Producing personalized apparel and accessories

D) Making custom phone cases and laptop skins - Which use of sublimation printers involves

printing on ceramic and glass materials?

A) Custom phone cases and laptop skins

B) Personalized mugs and water bottles

C) Photo prints and artwork

D) Signage and displays - .What is a common use of sublimation printers in

the textile industry?

A) Printing on paper and fabric

B) Creating custom phone cases and laptop skins

C) Producing personalized apparel and accessories

D) Making custom signage and displays - Which industry uses sublimation printers to

create custom products for events and trade shows?

A) Healthcare

B) Retail

C) Hospitality

D) Events and Exhibitions - What is a popular use of sublimation printers in

the photography industry?

A) Printing on metal and wood

B) Creating custom phone cases and laptop skins

C) Producing personalized photo albums and frames

D) Making custom signage and displays - Which use of sublimation printers involves

printing on metal and wood materials?

A) Custom phone cases and laptop skins

B) Personalized mugs and water bottles

C) Photo prints and artwork

D) Signage and displays - What is the common use of sublimation printers

in the gifting industry?

A) Creating custom phone cases and laptop skins

B) Producing personalized mugs and water bottles

C) Making custom signage and displays

D) Producing personalized gifts and novelties - Which industry uses sublimation printers to create

custom products for fundraising and awareness

campaigns?

A) Healthcare

B) Retail

C) Hospitality

D) Non-profit Organizations

PART C

Fill in the gap with the correct answer

- _____________ holds the sublimation ink that is

used for printing. - ______________ is a mechanism that grips and

feeds the sublimation paper through the printer - ______________is a moving carriage that holds

the print head. - _____________is a specialized ink jet printer.

- _____________ first discovered the concept of

sublimation printer - The development of digital sublimation printers

was in the year _____________ - ______________ is the interface that allows users to

operate the printer. - ______________is a heating element that preheats the

sublimation printer. - ______________ is a container that collects the excess

ink. - _____________is a mechanism that winds up printed

paper. - The first sublimation printer was developed using

a _____________ - The introduction of the ink jet technology

revolutionized sublimation printer in the year

________________. - _____________ is a type of inkjet printer that uses heat to

transfer dye on to materials.

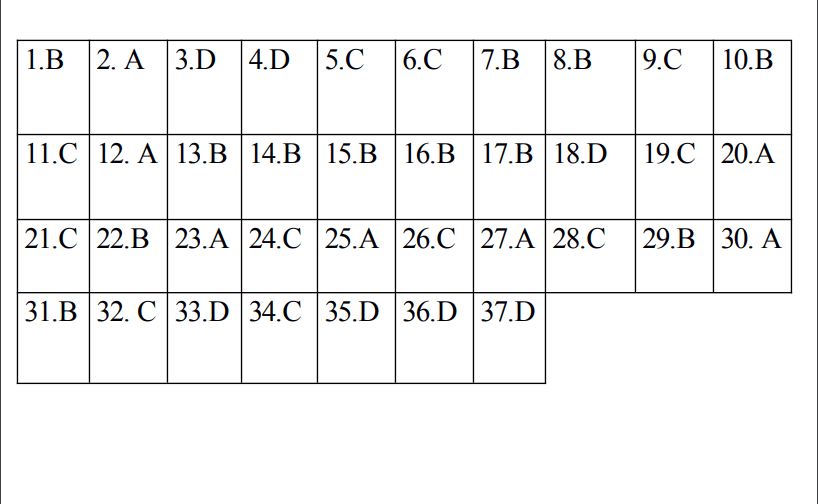

Instructors copy

Answers to the multi choice question 1- 37

ANSWERS TO THE FILLING THE GAP

QUESTION 38-50

38.INK TANK

- DOUBLE LAYER PINCH ROLLER

- HEAD CARRIAGE

- SUBLIMATION PRINTER

- MARC GREGOIRE

- 1990

- CONTROL PANEL

- BACK HEATING

- WASTE TANK

- TAKE UP DEVICE

- DYE DIFFUSING THERMAL TRANSFER

- 1980

- SUBLIMATION PRINTER