20 minutes Read

Introduction

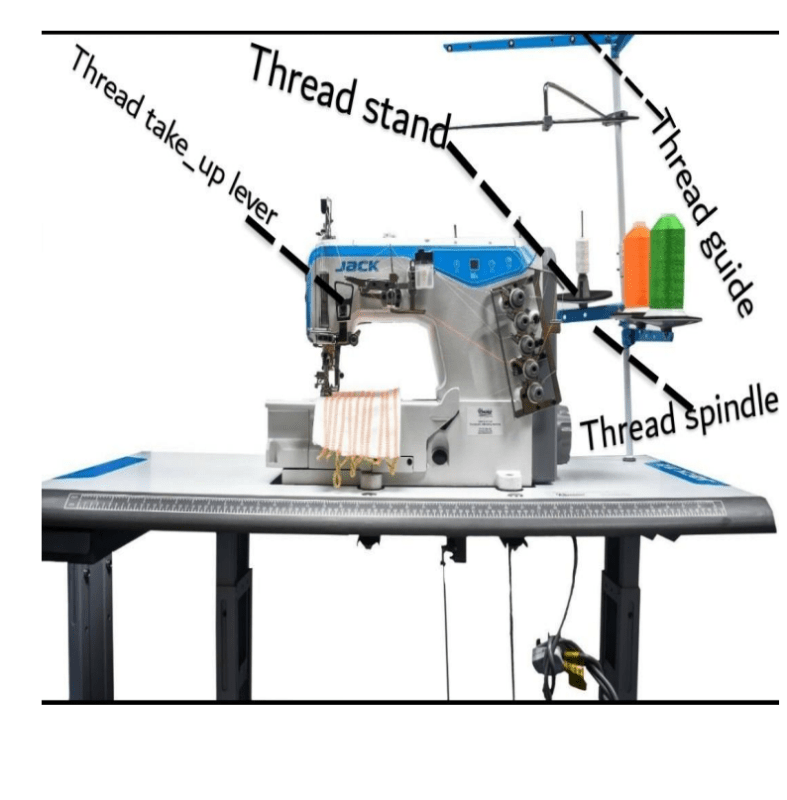

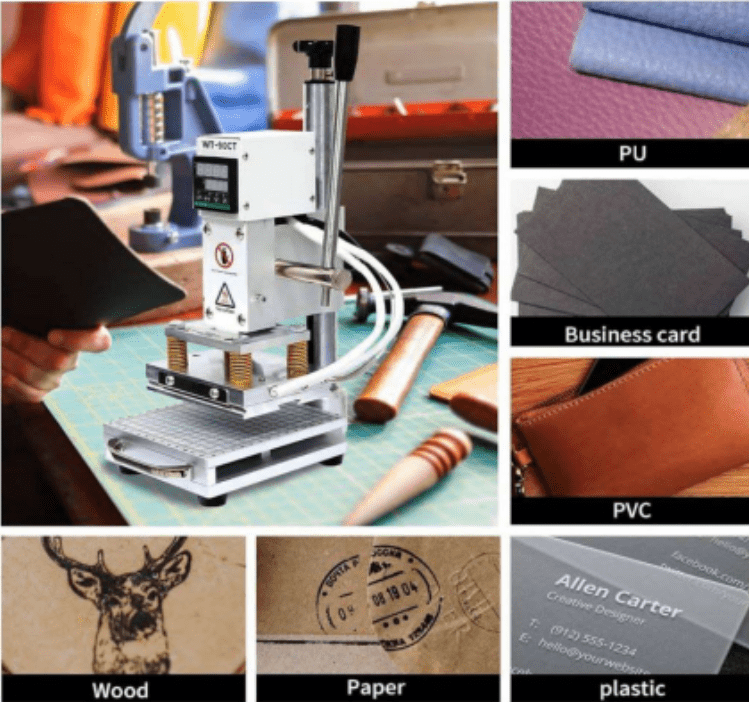

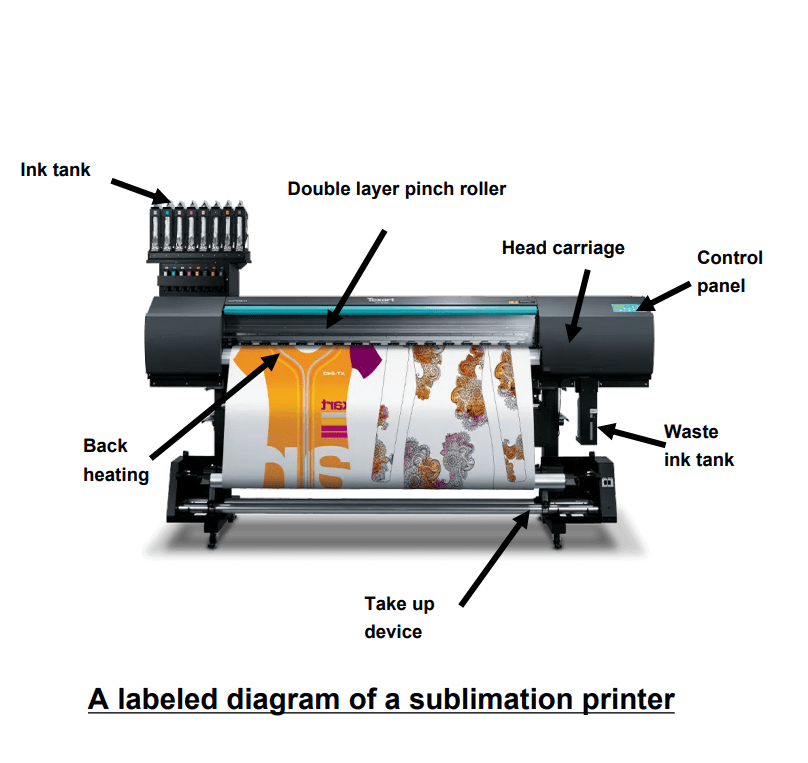

HEAT PRESS MACHINE

Ever wondered how those stunning custom designs on your

favorite T-shirt are made? The answer might surprise you: It’s

the magic of the heat press machine.

A heat press machine, also known as a heat transfer press, is a

piece of equipment used to transfer a design, image, or text

onto a substance or substrate using heat and pressure. More

specifically, a heat press machine typically applies heat,

pressure, and time to a transfer paper or vinyl that has been

printed with an image or design, then transfers that image or

design onto a substrate through melting of the pigment onto

the material.

Common substrates that can be decorated using a heat press

machine include fabrics, such as T-shirts, bags, and hats, as well

as metal, plastic, and paper.

There are several types of heat press machines, including

manual, semi-automatic, and automatic. Manual machines are

operated by hand and require more effort from the user to

control pressure and temperature. Automatic machines are fully

automated and require less effort from the user, but are

typically more expensive than manual machines.

Heat press machines are versatile pieces of equipment that can

be used for both personal and commercial purposes. For

personal use, a heat press machine is an ideal tool for creating

customized gifts, garments, and accessories. These machines,

typically smaller and less expensive than commercial models,

can handle smaller substrates and typically operate at lower

temperatures and pressures. Personal heat press machines are

often used for projects such as creating personalized T-shirts,

hats, tote bags, and other personalized gifts. On the other hand,

commercial grade heat press machines are designed for larger

production runs and are intended to be used in a business or

manufacturing setting. Commercial heat press machines are

typically larger and more expensive than personal machines,

and are capable of handling larger substrates and operating at

higher temperatures and pressures. They are often used for

projects such as creating large orders of customized T-shirts, as

well as printing large-scale graphics on banners, posters, and

billboards.

The maximum temperature varies based on the type of

machine, but it is typically around 400°F. The required voltage

also varies based on the type of machine, but it is typically

around 100-240V. It can take 10-15 minutes for a heat press

machine to heat up fully.

PROCESS INVOLVED IN USING A HEAT PRESS

MACHINE

The process of using a heat press machine involves several

steps:

- Prepare the substrate: The substrate is the material that you

will be applying the design onto, such as a T-shirt or bag. It

should be cleaned and prepped to remove any dirt or debris. - Prepare the design: The design needs to be printed onto

transfer paper or vinyl using a printer or design software. Make

sure the design is correctly sized and mirrored if needed. - Set up the heat press machine: Set the temperature,

pressure, and time according to the instructions for the

substrate and transfer paper/vinyl being used. - Position the substrate: Place the substrate onto the heat

press machine platen where the design will be transferred onto,

making sure it is straight and centered. - Position the transfer paper/vinyl: Place the printed design

transfer paper/vinyl onto the substrate, making sure it is

centered and aligned. - Apply heat and pressure: Close the heat press machine and

apply the required temperature and pressure for the specified

time. - Remove the transfer paper/vinyl: Open the heat press

machine, and carefully remove the transfer paper/vinyl from the

substrate. - Cool down and inspect: Let the substrate cool down and

inspect the design transfer for any issues, such as incomplete

transfers or unwanted marks or lines.

When working with a heat press machine, it is essential to

follow the instructions carefully, particularly regarding heat,

pressure and time, to achieve the desired results.

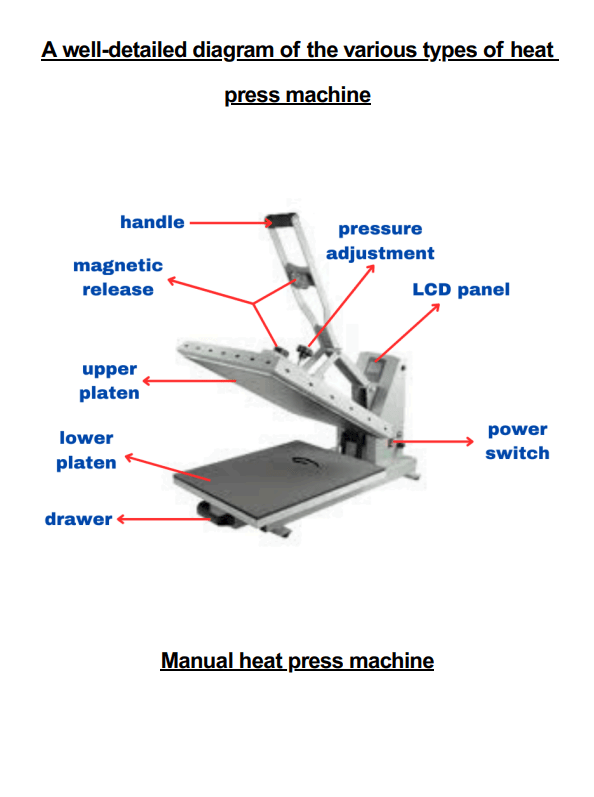

Manual heat press machine

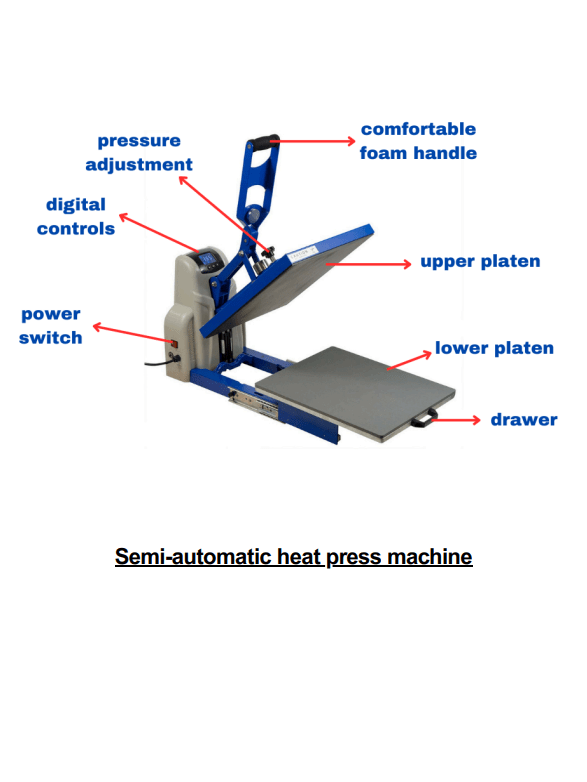

Semi automatic heat press machine

Automatic roller heat press machine

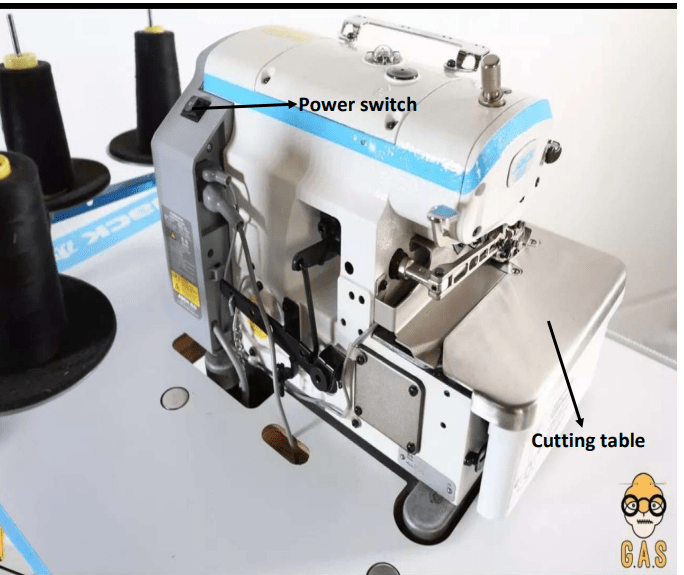

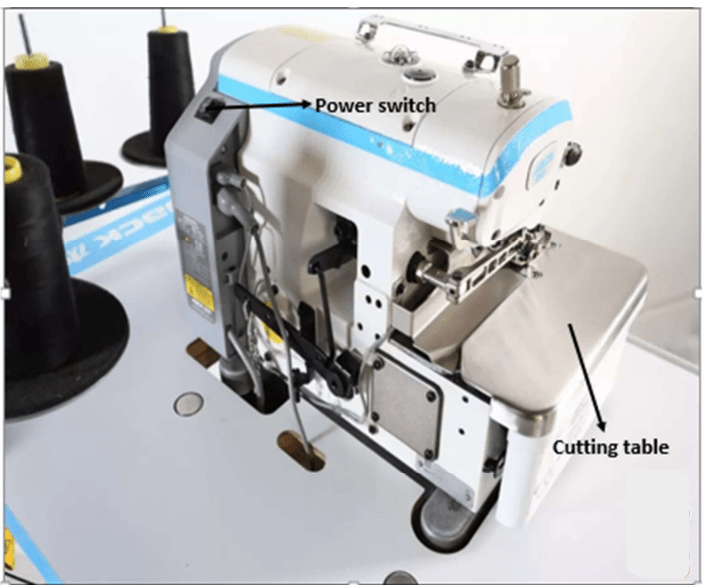

The parts of a heat press machine and their uses are as follows:

- Platen: This is the flat plate that heats up and presses against

the substrate and transfer paper/vinyl. It is typically made of

metal and comes in various sizes and shapes. - Temperature control: This controls the temperature of the

platen, which is crucial to ensure that the transfer paper/vinyl

adheres to the substrate correctly. - Pressure control: This controls the amount of pressure

applied to the substrate and transfer paper/vinyl during the

transfer process. It is essential to achieve the correct amount of

pressure to ensure an even, complete transfer. - Timer: This sets the amount of time for the transfer process,

which is dependent on the substrate and transfer paper/vinyl

being used. - Control panel: This is used to adjust the temperature,

pressure, and time settings for the machine. - Base and frame: This supports the machine and its

components and is typically made of metal. - Handle: This is used to open and close the machine to apply

pressure to the substrate and transfer paper/vinyl. - Heat-resistant pad: This is a pad that is often included with

the machine and placed under the substrate to help distribute

heat and protect the machine from excessive wear and tear. - Emergency shut off: This is a safety feature that allows the

machine to be shut off immediately in case of an emergency. - Power switch: This turns the machine on and off.

Understanding the different parts of a heat press machine is

essential for operation, maintenance, and troubleshooting to

ensure that the machine works efficiently and safely.

USES OF THE HEAT PRESS MACHINE

The heat press machine is used for many different

applications, including: - Customized apparel: Heat press machines can create custom

T-shirts, hats, bags, and other fabric-based products with

personalized designs, logos, and images.

Above is an image of customized apparels made with the heat

press machine.

- Promotional items: Heat press machines can be used to

create promotional items for events, such as branded tote bags,

badges, and other giveaways. - Sport steam apparel: Heat press machines can be used to

customize sport steam apparel with team logos, names, and

numbers. - Corporate merchandise: Heat press machines can be used to

create corporate merchandise, such as branded jackets, T-shirts,

and other apparel for corporate events and promotional

campaigns. - Home decor: Heat press machines can be used to create

customized home decor items, such as personalized cushion

covers, curtains, and table cloths. - Arts and crafts: Heat press machines can also be used for arts

and crafts projects, such as creating custom notebooks, phone

cases, and other personalized items.

Overall, the heat press machine is a versatile piece of equipment

that can be used to add custom designs and logos to a variety of

different items, making it an essential tool for businesses, sports

teams, and hobbyists alike.

BENEFITS OF THE HEAT PRESS MACHINE

There are several benefits of the heat press machine,

including:

- Versatility: Heat press machines can be used on a variety of

substrates, including fabric, metal, plastic, and paper. - Customization: Heat press machines allow for easy

customization, enabling users to create unique and personalized

items. - Long-lasting designs: The designs and logos applied with heat

press machines are long-lasting, durable, and resist fading. - Professional quality: Heat press machines produce high quality results, creating a professional finish that adds value to

custom items. - Time efficient: Heat press machines are quick and easy to

use, enabling users to produce multiple items in a short amount

of time. - Cost-effective: Heat press machines are a cost-effective

method of creating customized items, eliminating the need for

expensive equipment and processes. - Eco-friendly: Heat press machines use Eco-friendly ink options

and do not use any hazardous chemicals in the process.

Overall, a heat press machine is an essential tool for anyone

looking to create personalized and customized items with a

professional finish. Its cost-effectiveness, versatility, and ease of

use make it an increasingly popular choice for individuals and

businesses alike.

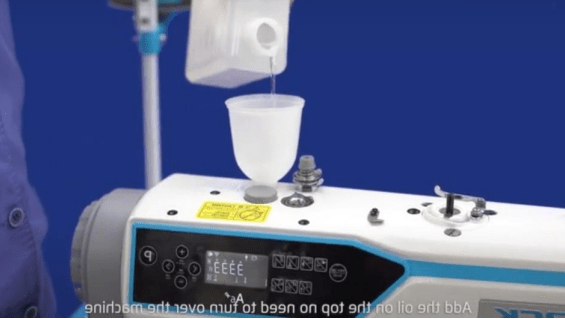

MAINTENANCE OF THE HEAT PRESS MACHINE

Proper maintenance of a heat press machine is crucial to

ensure optimal performance and longevity. Here are some

maintenance tips for a heat press machine: - Keep the machine clean: Wipe down the platen and the

entire machine with a soft cloth after each use. Avoid using

harsh chemicals on the machine. - Ensure proper pressure: Check the pressure on the machine

regularly to ensure that it is set properly. If the pressure is too

low, the transfer may not adhere properly to the substrate. If the

pressure is too high, it may damage the machine. - Check the temperature regularly: Test the temperature of the

platen regularly to ensure that it is heating up properly. If the

temperature is fluctuating, it may be time to replace the heating

element. - Lubricate moving parts: Lubricate the moving parts, such as

the handle, with a light machine oil to ensure they move

smoothly. - Replace worn parts: Check the machine regularly for any

worn or damaged parts, such as the heating element, pressure

knob, and the silicone pad. Replace these parts as needed to

ensure optimal performance. - Store the machine properly: To prevent any damage or

issues, store the machine in a clean, dry, and secure location

when not in use. - Follow manufacturer’s instructions: Read and follow the

instructions provided by the manufacturer for operation,

maintenance, and troubleshooting to ensure proper use of the

machine.

By properly maintaining a heat press machine, it will continue to

produce high-quality, professional-grade results for a long time.

SAFETY PRECAUTIONS TO BE TAKEN WHEN

OPERATING A HEAT PRESS MACHINE

It is very important to take safety precautions when using a

heat press machine as they involve high temperatures and

pressure. Here are some safety precautions to follow while using

a heat press machine:

- Wear protective gear: Wear heat-resistant gloves when

operating the machine to prevent burns from coming in contact

with the hot platen. Also, wear protective clothing to avoid

contact with the exposure of hot steam and hot air. - Keep children and pets away: Keep children and pets away

from the heat press machine during use, as they can get hurt by

touching the hot surface or the machine’s moving parts. - Use proper voltage: Make sure the heat press machine is

connected to the proper voltage to avoid electrical shocks. - Avoid using damaged parts: Do not use a heat press machine

that has damaged parts, such as a torn silicone pad or a

damaged heating element. It can cause serious damage to the

machine and endanger the user. - Follow the recommended temperature and pressure

settings: Do not exceed the recommended temperature or

pressure settings, as it can cause the transfer paper or vinyl to

burn or melt. - Be alert and attentive: Always be alert and attentive while

operating the heat press machine. Avoid distractions and keep

your focus on the task at hand. - Turn off the machine after use: Turn off the heat press

machine after use to prevent accidental burns or damage to the

machine.

By taking these safety precautions, you can ensure that you

operate your heat press machine safely and effectively, avoiding

accidents and injuries.

SUMMARY

A heat press machine is a versatile device that transfers designs,

images or text onto different substrates using heat and pressure.

It operates by melting the pigment onto the material. The

machine can be used on a variety of materials including fabric,

metal, plastic, and paper. There are different types of heat press

machines such as manual, automatic, and semi-automatic. The

equipment is available in different sizes and is ideal for both

personal and commercial use. Heat press machines offer a lot of

benefits such as customization, long-lasting designs, and time

efficiency. Proper maintenance of the heat press machine is

essential to ensure optimal performance and longevity. Users of

the heat press machine should also take safety precautions to

avoid accidents and injuries.

Multi-choice Questions

Part A

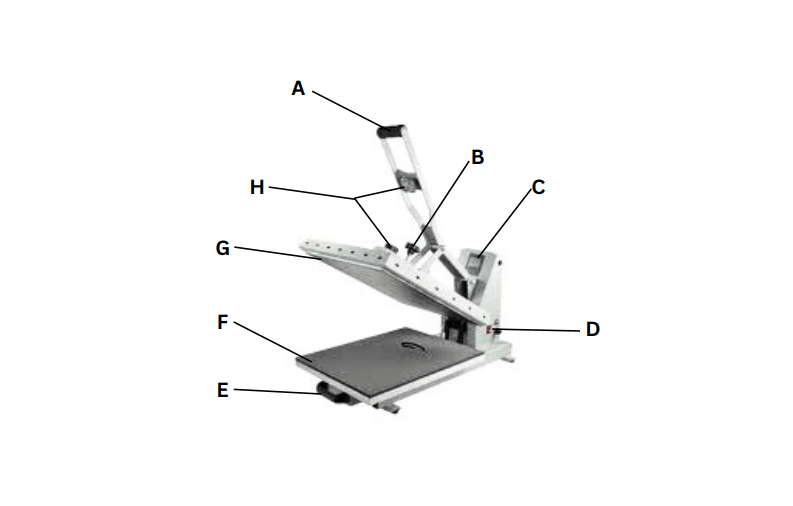

Using the diagram below answer question 1-8 by naming the

components labeled A-H

1.The component labeled A is known as ______________

A) Handle

B) Drawer

C) Control Panel

D) Temperature control

2.The component labeled B is known as ____________

A) Breaker Reset

B) On/Off Switch

C) Pressure Adjustment

D) Rubber Pad

3.The component labeled C is known as____________

A) Rubber stand

B) LCD Panel

C) Working button

D) Slide-able Workbench

4.The component labeled D is known as____________

A) Feeding rate handle

B) Upper Platen

C) Rubber Pad

D) Power Switch

5.The component labeled E is known as _______________

A) Slide-able Workbench

B) Lower Platen

C) Cooling

D) Pressure control handle

6.The component labeled F is known as______________

A) Slide-able Workbench

B) Lower Platen

C) Cooling

D) Pressure control handle

7.The component labeled G is known as _____________

A) Heating Time

B) Upper Platen

C) Rubber Pad

D) Feeding rate handle

8.The component labeled H is known as ___________

A) Rubber Pad

B) Power Switch

C) Pressure control handle

D) Magnetic Release

Part B

Pick the right option in each question among the answers listed

below

- What is a heat press machine?

A) A heat press machine is a piece of equipment used to transfer

a design, image, or text onto a substance or substrate using heat

and pressure

B) A heat press machine is an electron device that stores and

process data

C) A heat press machine is a machine that regulates the

temperature of a room

D) A heat press machine is a machine that prints paper - Common substrates that can be decorated using a heat

press machine include all except?

A) T-shirt

B) Rock

C) Metal

D) Paper - Which of the following is a type of heat press machine?

A) Nuclear heat press machine

B) Semi-automatic heat press machine

C) Analog heat press machine

D) Aquatic heat press machine - Processes involved in using a heat press machine includes

the following except?

A) Prepare the substrate

B) Prepare the design

C) Thread the needle

D) Set up the heat press machine - Processes involved in using a heat press machine includes

the following except?

A) Position the substrate

B) Position the transfer paper

C) Apply heat and pressure

D) Apply lubricant to the platen - The following are parts of a heat press machine except?

A) Powers witch

B) Handle

C) Drawer

D) Propeller - The following are parts of a heat press machine except?

A) Pressure control

B) Emergency shut off

C) Neck

D) Platen - The following are uses of a heat press machine except?

A) Home decor

B) Moving heavy items

C) Sport steam apparel

D) Corporate merchandise - The following are benefits of a heat press machine except?

A) Time wasting

B) Eco-friendly

C) Long-lasting designs

D) Customization - Which of the following is a way to maintain a heat press

machine?

A) Pour water on it

B) Check the temperature regularly

C) Keep under harsh weather conditions

D) Use without reading manufacturer’s instructions - The following are ways to maintain a heat press machine

except?

A) Keep the machine clean

B) Ensure proper pressure

C) Lubricate moving parts

D) keep using worn parts - Which of the following is a precaution to be taken when

using a heat press machine?

A) Allow children access to the heat press machine

B) Allow temperature to over-heat

C) Wear protective gear

D) keep using worn parts - How long does it take to heat up a heat press machine?

A) 1 hour

B) 48 hour

C) 30 minutes

D) 10-15 minutes - Which of the following heat press machine requires more

effort from the user to operate?

A) Automatic heat press machine

B) Semi-automatic heat press machine

C) Manual heat press machine

D) Nuclear heat press machine - Which of the following heat press machine requires less

effort from the user to operate?

A) Automatic heat press machine

B) Semi-automatic heat press machine

C) Manual heat press machine

D) Nuclear heat press machine - Which of the following heat press machine is the most

expensive?

A) Automatic heat press machine

B) Semi-automatic heat press machine

C) Manual heat press machine

D) Nuclear heat press machine - What is the function of a heat press machine?

A) The function of a heat press machine is to solve world

financial problems

B) The function of a heat press machine is to transfer designs

onto different substrates.

C) The function of a heat press machine is to print paper

D) The function of a heat press machine is to regulate the

temperature of a room - How does a heat press machine operate?

A) The machine operates by melting the pigment onto the

material

B) The machine operates with the use of arithmetic and logic

unit

C) The machine operates through radioactive means

D) The machine operates with the use of a propeller - The following are precaution to be taken when using a heat

press machine except?

A) Turn off the machine after use

B) Allow temperature to over-heat

C) Wear protective gear

D) Use proper voltage - What is the maximum temperature of a heat press

machine?

A) 100°C

B) 100°F

C) 400°F

D) 400°C - What is the required voltage of a heat press machine?

A) 150-200V

B) 100-240V

C) 100-500V

D) 200-240V

Part C:

Fill in the gap with the appropriate answer

- A heat press machine, also known as a heat transfer press, is

a piece of equipment used to transfer a design, image, or text

onto a substance or substrate using___________ - There are several types of heat press machines, including___________

,___________ and __________ - Automatic heat press machines are fully automated and

require ________effort from the user. - Manual heat press machines are fully operated by hand and

require __________effort from the user. - The temperature control adjusts the temperature of the

___________,which is crucial to ensure that the transfer

paper/vinyl adheres to the substrate correctly. - A heat press machine operates by melting the pigment onto

the _____________, - A heat press machine is used to transfer designs, images, or

text onto a __________ . - The maximum temperature reached by a heat press

machine is typically around __________ degrees Fahrenheit. - A heat press machine can be preheated for___________

minutes before transferring a design onto a substrate to ensure

even heat distribution. - A heat press machine can be used for multiple transfers in

one project by adjusting the__________ and__________

settings between each transfer. - Heat press machines can use up to _________volts of

electricity, depending on the model. - A heat press machine can be used for personal projects or

for __________ purposes. - The size of a heat press machine will vary based on its

intended use which can be____________ or____________ . - The cost of a heat press machine can vary based on it’s

__________ and purpose. - The pressure on a heat press machine can be adjusted by

adjusting the __________ knob on the machine. - The __________is the material that you will be applying the

design onto. - Wear appropriate protective gear, such as ______________

when handling the heat press machine to prevent burns from

coming in contact with the hot platen. - The heat press machine should be kept away from

___________ and ___________during use, as they can get hurt

by touching the hot surface or the machine’s moving parts. - _________parts of the heat press machine should be

replaced to ensure optimal performance. - ___________ should be applied to moving parts of the heat

press machine to ensure they move smoothly. - Make sure the heat press machine is connected to the

__________ to avoid electrical shocks