22 Minute read

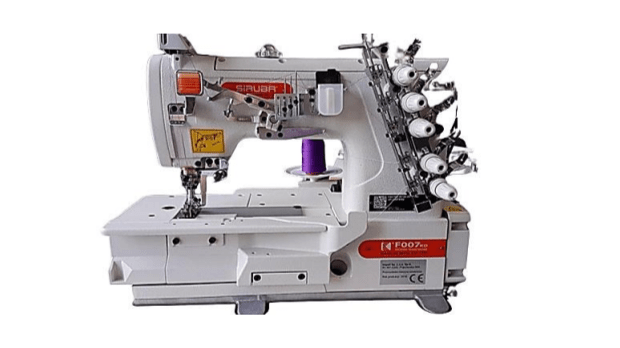

Definition:

A double needle machine is a sewing machine that

uses two needles and two bobbins to create two

parallel rows of lockstitch. This type of machine is

also known as a twin needle machine. The two

needles are attached to a single shank, with one

needle being slightly shorter than the other to allow

for the bobbin thread to catch both threads.

A Full Description Of A Double Needle

Sewing Machine

A double needle sewing machine is a type of sewing

machine that has two needles and two bobbins,

allowing for the creation of two parallel rows of

lockstitch. Here are some key features that describe a

double needle sewing machine:

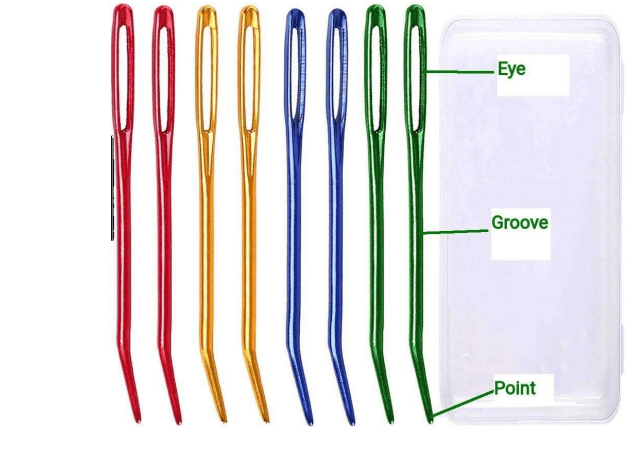

1.Two needles: The machine has two separate

needles, one slightly shorter than the other,

which are attached to a single shank.

2.Two bobbins: The machine has two bobbins,

one for each needle, which holds the thread.

3.Parallel stitching: The machine creates two

parallel rows of lockstitch, with each needle

sewing a separate row.

4.Adjustable needle distance: The distance

between the two needles can be adjusted to

change the width of the stitching.

5.Zigzag stitch: Double needle machines typically

have a zigzag stitch option, which allows for

stretchy seams and decorative stitching.

6.Two thread sources: The machine has two

separate thread sources, one for each needle,

which can be used to create contrasting or

matching threads.

7.Synchronized stitching: The machine’s

mechanisms are designed to synchronize the

stitching of both needles, ensuring consistent and

even stitch.

Double needle sewing machines are commonly used

for sewing stretchy fabrics, such as knits, and for

decorative stitching on woven fabrics. They are also

useful for sewing two rows of stitching at once,

saving time and effort

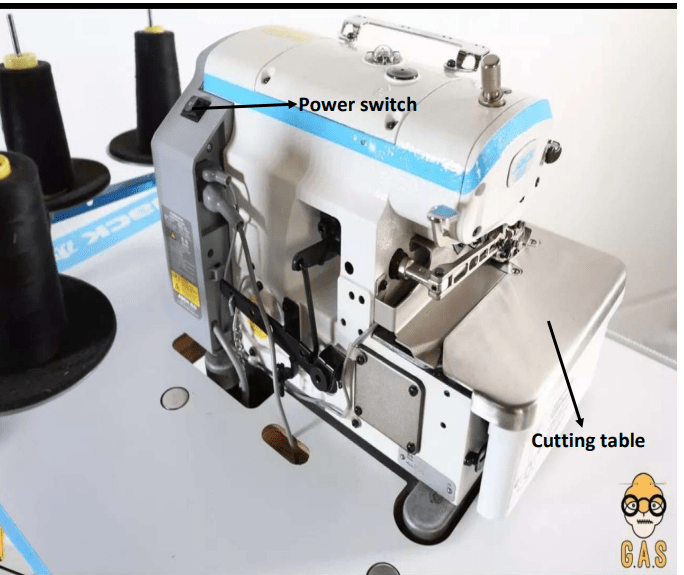

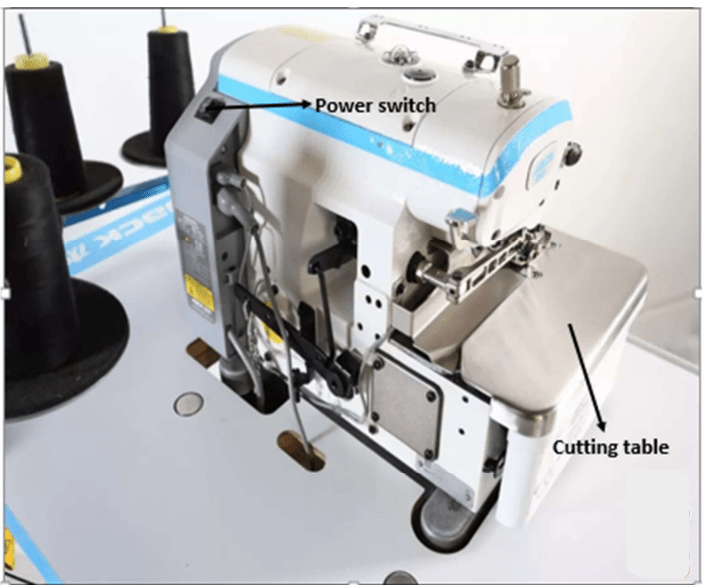

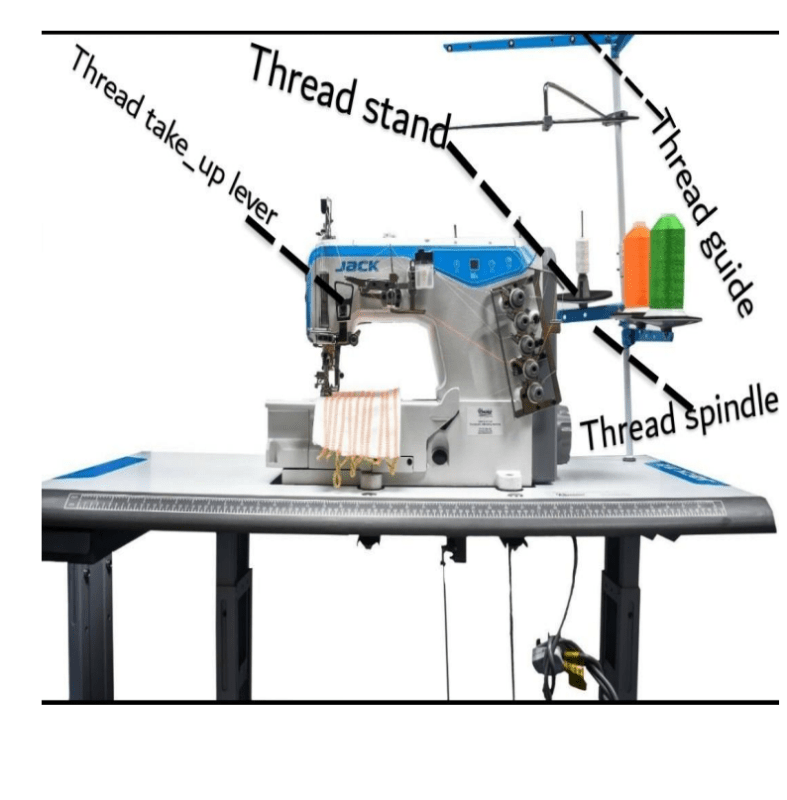

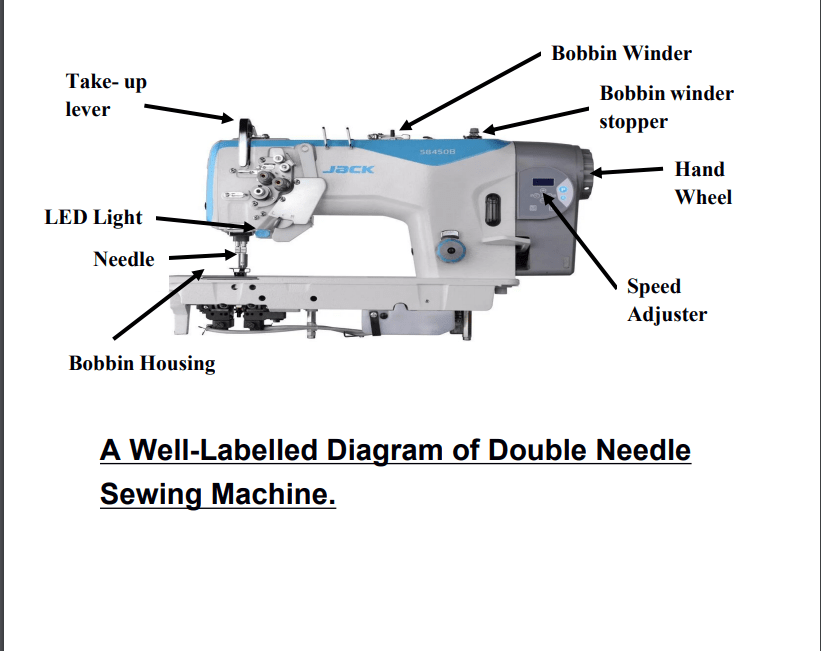

The Function Of The Labelled Parts Of The

Double Needle Sewing Machine.

- Feed dogs: it is responsible for moving the fabric

forward as you sew - Tension selection panel: it is responsible for the

selection of different stitches. - Bobbin winder: it is responsible for the winding

of the thread onto the bobbin - Thread take-up: sit is responsible for the raising

and lowering of the thread to form the stitch - Presser foot: it is responsible for the holding of

the fabric as you sew. - Bobbin case: it is responsible for the holding of

the bobbin. It also guides the thread from the bobbin

to the needle. - Bobbin compartment: it is responsible for the

housing of the bobbin case. It also allows easy access

to remove and replace the bobbin. - Reverse lever: it allows the sew in reverse. it is

also used to reinforce the stitches at the beginning

and end the seam. - Foot pedal: it controls the speed of the machine. It

allows the user to sew at a consistent pace. - Spool pin: it is responsible for holding the thread

pool in place. It guides the thread from the spool to

the needle. - Balance wheel: it is responsible for the manual

rotation of the machine’s mechanism. It is also

known as handwheel. - Stitch width regulator: it controls the width of

the stitch and allows the user to adjust the width to

suit the different fabrics and sewing projects. - Stitch length regulator: Controls the length of

the stitch.

Uses And Benefits Of A Double Sewing

Machine

1.High Efficiency: Double needle machines can

stitch in two directions at once, reducing the

production cycle time compared to a typical

single needle machine.

2.Stability and Reliability: Double needle

machines ensure the firmness and durability of

the sewing thread, making them suitable for

materials that need to withstand greater tension

and pressure.

3.Intelligent: Modern double needle machines are

equipped with electronic control systems and

displays that allow parameters to be set and

adjusted as needed.

4.Decorative Effects: Double needle stitching

creates beautiful decorative effects like pintucks,

hemming and decorative seeming.

5.Durability: Garments sewn with double needle

machines are more durable thanks to the double

rows of reinforced stitching.

6.Thicker Materials: Double needle machines

can easily stitch through materials like denim,

canvas, or leather.

7.Ease of Use: Modern double needle sewing

machines feature intuitive controls, quick set-up,

and easy maintenance.

8.Cost Savings: Double needle machines provide

significant cost savings over time thanks to their

efficiency, versatility, and durability.

9.Applicability: Double needle machines are

widely used in garment manufacturing,

automobile interiors, furniture manufacturing,

shoe and hat making, and other industries.

10.Productivity: Double needle machines can

significantly boost efficiency and productivity,

allowing workers to accomplish more sewing

tasks in less time, reducing labor costs.

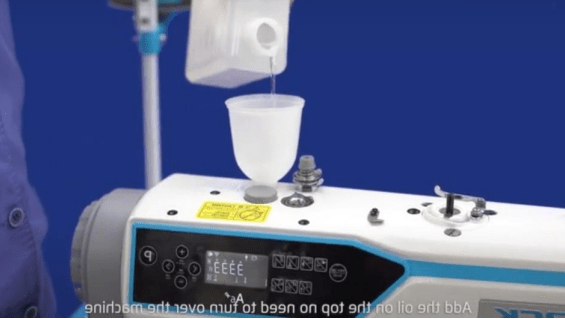

How To Maintain A Double Needle

Sewing Machine

- Read the manual: Before using the machine, read

the user manual to understand its specific features

and guidelines. - Wear protective gear: Wear protective glasses,

gloves, and a dust mask to prevent injury from flying

debris, needle pricks, and inhalation of lint and dust. - Keep long hair tied back: Long hair can get

caught in the machine’s moving parts, so keep it tied

back and away from the machine. - Avoid loose clothing: Wear tight-fitting clothing

and avoid loose sleeves or accessories that could get

caught in the machine. - Keep children away: Double needle sewing

machines can be hazardous for children, so keep

them at a safe distance. - Use the correct needles: Use needles specifically

designed for double needle machines to prevent

breakage and injury. - Keep fingers away from needles: Keep your

fingers away from needles and other moving parts to

prevent injury. - Use a walking foot or Teflon foot: These

specialized feet help guide the fabric smoothly and

prevent bunching or dragging, reducing the risk of

accidents. - Don’t sew over pins: Sewing over pins can cause

the machine to jam or break and may also cause

injury. - Unplug When Not in Use: Unplug the machine

when not in use to prevent accidental start-ups and

reduce the risk of electrical shock.

By following these safety precautions, you can

minimize the risk of injury and ensure a safe and

successful sewing experience with your double

needle sewing machine.

Processes Involved In Using A Double

Needle Sewing Machine

- Threading: Thread both needles and bobbins with

the desired thread, making sure to keep the threads

separate and untangled. - Setting the stitch length and width: Adjust the

machine’s settings to determine the length and width

of the stitches. - Selecting the stitch type: Choose the desired

stitch type, such as a straight stitch or zigzag stitch. - Placing the fabric: Position the fabric under the

presser foot, ensuring it is aligned and smooth.

- Starting the machine: Begin sewing by slowly

turning the handwheel or pressing the start button. - Guiding the fabric: Use the presser foot and

guides to keep the fabric moving smoothly and

evenly. - Maintaining tension: Monitor and adjust the

thread tension as needed to prevent loose or tight

stitches. - Backstitching: Reinforce the beginning and end

of the seam with a few reverse stitches. - Cutting the threads: Cut the threads with scissors

or a thread cutter. - Inspecting the stitches: Check the stitches for

quality and consistency. - Adjusting the needles: Adjust the needle

distance and tension as needed for different fabrics

and stitches. - Cleaning the machine: Regularly clean the

machine to prevent lint and debris buildup.

By following these processes, you can effectively

use a double needle sewing machine to create strong,

professional-looking seams and decorative stitches.

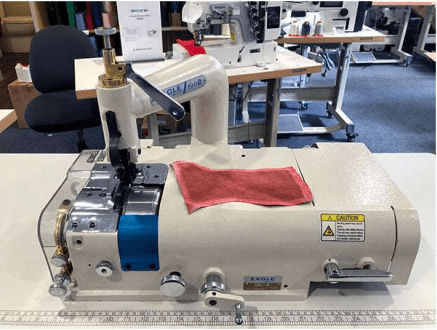

How The Mechanism Of The Double Needle

Sewing Machine Works

A double needle machine, also known as a double

needle sewing machine, is a type of sewing machine

that uses two parallel needles to create two parallel

rows of stitches. This mechanism allows for faster

and more efficient sewing, particularly for straight

stitching and hemming. A diagram will be shown

below to help explain the mechanism.

Here’s a breakdown of the mechanism:

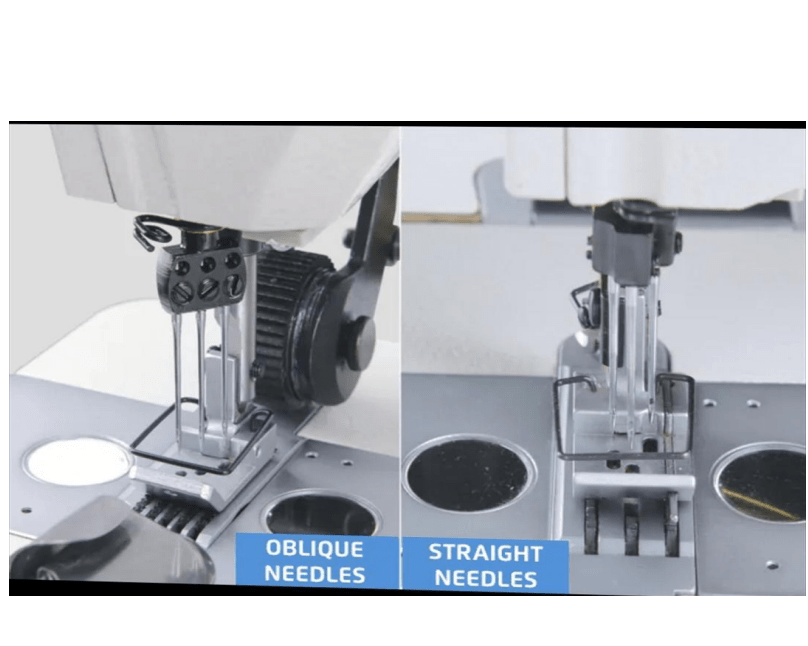

- Two parallel needles: The machine has two

needles, one on either side of the presser foot, spaced

a fixed distance apart (usually 1/4 inch or 6 mm). - Two separate threads: Each needle has its own

thread, which is fed through a separate tension disc

and take-up lever. - Synchronized motion: The two needles move up

and down in a synchronized motion, creating two

parallel rows of stitches. - Alternating stitches: The machine alternates

between the two needles, creating a stitch with one

needle and then the other, in a continuous cycle. - Presser foot: The presser foot holds the fabric in

place, guiding it smoothly under the needles as they

move up and down. - Tension control: The machine has separate

tension controls for each thread, allowing for

adjustments to be made for different fabric types and

stitch lengths. - Stitch length control: The machine typically has a

stitch length control, allowing the user to adjust the

length of the stitches.

The double needle machine mechanism enables

efficient sewing of straight lines, hems, and edges,

making it a popular choice for garment construction,

home decor, and quilting projects.

Safety Precaution to Be Taken When Using

A Double Sewing Machine

When using a double needle sewing machine, it’s

important to take certain safety precautions to avoid

accidents and injuries. Here are some safety tips to

keep in mind:

- Read the manual: Before using the machine, read

the user manual to understand its specific features,

settings, and guidelines. - Wear protective gear: Wear protective eyewear,

gloves, and a dust mask to prevent eye strain, cuts,

and inhalation of fabric dust. - Keep fingers away: Keep your fingers at least 1

inch (2.5 cm) away from the needles to avoid getting

pierced or caught. - Use the presser foot: Always use the presser foot

to guide the fabric, keeping your hands away from

the needles. - Keep the work area clear: Ensure the work area

is clear of clutter, lose threads, and other obstructions

to prevent accidents. - Use the correct needle size: Use the correct

needle size and type for the fabric you’re working

with to prevent breakage and accidents. - Keep the machine well-maintained: Regularly

oil and clean the machine to prevent jamming and

other issues. - Use a walking foot or Teflon foot: Consider

using a walking foot or Teflon foot to help guide the

fabric smoothly and prevent bunching. - Keep children and pets away: Keep children and

pets away from the machine while it’s in use to

prevent accidents. - Take breaks: Take regular breaks to rest your

eyes, hands, and mind to prevent fatigue and

mistakes. - Use a needle guard: Consider using a needle

guard or needle shield to protect yourself from

accidental needle pricks. - Unplug when not in use: Unplug the machine

when not in use to prevent accidental start-ups and

electrical shocks.

By following these safety precautions, you can minimize the risk of accidents and enjoy safe and

successful sewing with your double needle machine

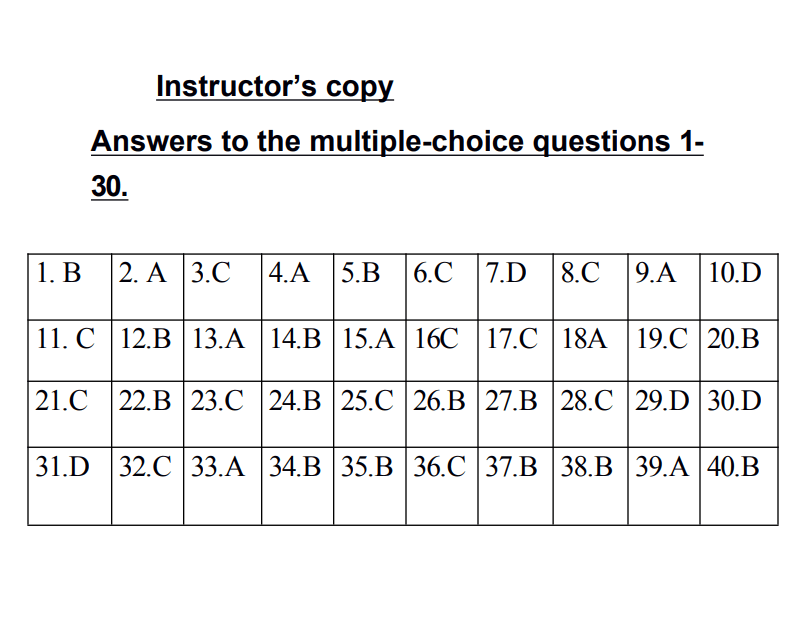

Multi-Choice Questions

Part A

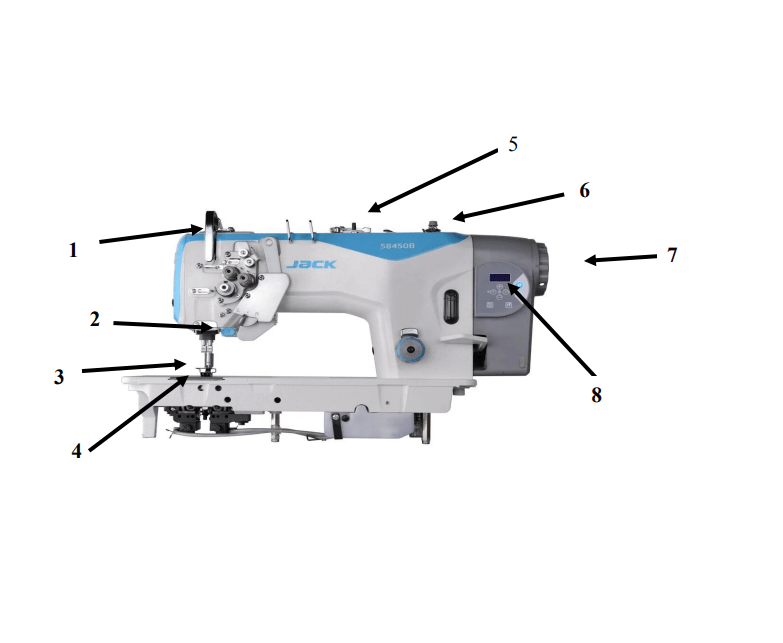

From The Diagram Above Fix In The Correct

Parts That Matches The Number.

- The part labelled 1 is called?

A. Thread guide

B. Thread take- up

C. Needle

D. Bobbin - The part labelled 2 is called?

A. Led light

B. Foot pedal

C. Spool thread

D. Reverse level - The part labelled 3 is called?

A. Bobbin compartment

B. Needle feed dog

C. Needle

D. Presser foot lift - The labelled part 6 is called?

A. Bobbin winder stopper

B. Stitch length regulator

C. Stitch selection panel

D. Balance wheel - the part labelled 5 is called?

A. Winder

B. Bobbin Winder

C. Stitch Width Regulator

D. Foot Pedal - The part labelled 4 is called?

A. Thread take up

B. Needle

C. Bobbin housing

D. Bobbins - The part labelled 8 is called?

A. Bobbin case

B. Bobbin wheels

C. Stitch

D. Speed adjuster - The part labelled 7 is called?

A. Balance stitch

B. Needle case

C. Hand wheel

D. Stitch length regulator - The part labelled 12 is called?

A. Stitch length regulator

B. Needle compartment

C. Thread base

D. Needle guide

Part B

Pick the right options in each question among the

answers listed below.

- Which part of the machine provides illumination.

A. Stitch compartment

B. Stitch base

C. Balance stitch case

D. LED light - A small mechanism that stops the bobbin winder

is called?

A. Reverse wheel

B. Reverse panel

C. A bobbin winder stopper

D. Spool pin - Which part of the machine holds the bobbin in

place?

A. Spool thread

B. Bobbin housing

C. Bobbin

D. Foot pedal - a double needle sewing machine can do various

stitches except?

A. Needle stitch

B. Zigzag stitches

C. Decorative stitch

D. Straight stitch - What are the common issues with double needle

sewing machine except?

A. Uneven tension

B. Even needles

C. Needle breakage

D. Thread tangling - When threading make sure to keep the Thread?

A. Closer

B. Separate and tangle

C. Far and wide

D. Near - How do you start a double needle sewing

machine?

A. Thread case

B. Thread take up.

C. Press the start button

D. Bobbin compartment - The double needle sewing machine should be

cleaned?

A. Rarely

B. often

C. Regularly

D. Never - What should you wear to protect your eye from

flying debris when using a double needle sewing

machine.

A. Goggles

B. Glasses

C. Sunglasses

D. Contacts - Why should you keep long hair tied back when

using a double needle sewing machine?

A. To prevent hair from obstructing your view.

B. To prevent hair from getting tangled in the

machine.

C. To prevent hair from getting caught in the needle.

D. To prevent hair from falling on the fabric. - What should you do with loose clothing

accessories when using a double needle machine?

A. Keep them.

B. Remove them.

C. Tie them.

D. Tuck them in. - Why should children be kept away from the

double needle machine?

A. Because they might break it.

B. Because they might make a mess.

C. Because they might get hurt.

D. Because they might distract you. - What should you do when you notice a needle is

damaged or bent?

A. Keep using it.

B. Replace it.

C. Try to fix it.

D. Ignore it. - Why is it important to keep your fingers away

from the needles?

A. Because they might get dirty.

B. Because they might get tangled.

C. Because they might get hurt.

D. Because they might get stuck. - What should you do if the machine starts making

a strange noise?

A. Keep sewing.

B. Stop sewing and investigate.

C. Call a professional.

D. Unplug it. - Why is it important to use the correct needles for

a double needle sewing machine?

A. To prevent breakage.

B. To prevent tangling.

C. To prevent injury.

D. To prevent damage to the machine. - What should you do if you notice a thread is

tangled or knotted?

A. Keep sewing.

B. Stop sewing and untangle it.

C. Cut the thread.

D. Pull the thread harder. - Why is it important to unplug the machine when

not in use?

A. To prevent overheating.

B. To prevent electric shock.

C. To prevent damage.

D. To prevent theft. - By following safety precautions you can?

A. Reduce cost.

B. Increase production.

C. Minimize risk of accident.

D. Take a break. - Which part of the double needle sewing machine

holds the fabric in place?

A. Needle bar

B. Bobbling compartment

C. Presser foot

D. Presser lever - Which part of the double needle sewing machine

houses the bobbin case?

A. Bobbin compartment

B. Foot petals

C. Bobbin case

D. Reverse button - Which part of the double needle sewing machine

controls the speed of the machine?

A. Tension disc

B. Bobbin winder

C. Needle bar

D. Foot pedal - Which part of the double needle sewing machine

holds the thread in place?

A. Balance wheel.

B. Bobbin case.

C. Spool pin.

D. Stitch length regulator. - Which part of the double needle sewing machine

controls the width of the stitch?

A. Stitch width regulator

B. Width stitch controls.

C. Stitch controls

D. Length width regulator. - Which part of the double needle sewing machine

controls manual rotation?

A. Spool wheel

B. Balance wheel

C. Presser wheel

D. Machine body - What is the first step in threading a double needle

sewing machine?

A. Thread the needles.

B. Thread the bobbin.

C. Set the stitch length and width.

D. Place the fabric under the presser foot. - How do you select the correct stitch type on a

double needle sewing machine?

A. By adjusting the stitch length and width.

B. By changing the needle type.

C. By using the stitch selector dial.

D. By consulting the user manual. - How do you prevent thread tangling on a double

sewing machine?

A. By using a thread conditioner.

B. By keeping the thread taut.

C. By using a different thread type.

D. By using the bobbin tension. - How do you adjust the tension on a double

sewing machine.

A. By tightening the needle screw.

B. By adjusting the bobbin tension disc.

C. By changing the stitch length and width.

D. By using a different thread type. - What is the purpose of the balance wheel on a

double needle sewing machine?

A. To thread the machine.

B. To remove jams.

C. To adjust the stitch length and width.

D. To set the needle tension. - How do you maintain consistent stitching on a

double needle sewing machine?

A. By adjusting the stitch length and width.

B. By keeping the fabric smooth and flat.

C. By using walking foot.

D. By consulting the user manual

Part C

Fill in the gap with the appropriate answers.

- The double needle machine is also known as________________

- A double needle-machine has two needles that

are ___________ - A double sewing machine has __________.

- A balance wheel is also called a _________.

- In a double needle sewing machine the two

needles are attached to a ___________. - ______________are commonly used for sewing

stretchy fabrics. - Double needle machines can stitch in ____________

directions. - Fabric is positioned under the ___________ foot.

- ___________can be done to prevent jamming and

other issues. - ____________helps to prevent breakage in a double

needle sewing machine.

Answer the filling the gap question 41-50.

- TWIN NEEDLE MACHINE.

- SLIGHTLY SHORTER THAN THE OTHER.

- TWO NEEDLES AND TWO BOBBINS.

- HANDWHEEL.

- SINGLE SHANK.

- DOUBLE NEEDLE SEWING MACHINE

47.TWO DIRECTION. - PRESSER FOOT.

- REGULAR OILING AND CLEANING.

- USE OF CORRECT NEEDLE.