20 minute read

ENJOY READING !

Introduction

When trying to understand a vinyl cutter and how

it works, the best way to imagine it is to think of a

traditional printer. The printer receives data about

imagines from another source, usually a

computer, and then uses this to print images onto

a bit of paper.

This is like how a vinyl cutter works, only rather

than printing an image it relies on small blades to

cut the pattern of the image into the vinyl or other

material.

The first instance of a vinyl cutter was invented in

1888 when a Canadian inventor devised the

machine that could cut through fabric. This

machine was mounted onto a motor which was

then mounted on a platform which would serve as

the base for cutting.

Although bulky and difficult to operate, this

invention began the long line of cutting machines

that eventually led to the compact and efficient

variation we know today in home workshops

around the world.

Although traditionally owned and operated by

those in the sign making industry, vinyl cutters

are now more popular with those who enjoy arts

and crafts at home.

Because they are so versatile in what they can do

and allow for an aspect of creative freedom,

they’re now commonly found in home workshops

as they work well with a range of mediums and

are easy to operate.

There are different sizes and scales depending

on the type of work they’re used for, ranging from

compact desktop cutting machines to larger scale

professional grade devices used in workshops.

One of the reasons vinyl cutters have enjoyed

such huge success in both home and

professional workshops is due to the variety of

materials they can work with. Even the most

basic home desktop vinyl cutters can achieve

quite a lot, and they are an integral part in

producing many different types of arts and crafts

projects.

- Iron on transfers – with a vinyl cutter, you’re

able to design your own logos and patterns which

can be cut into iron on transfers and then placed

onto clothing. - Stickers – creating your own stickers with a vinyl

cutter means you can personalize the design and

print them as large or as small as your machine

will allow. - Signs – although commonly used for sign printing

businesses, it is possible for the home hobbyist to

cut through vinyl and other adhesives to create

signs for windows, walls, and other surfaces. - Magnets – a quality vinyl cutter will allow you to

make refrigerator magnets for your home or

business, and you can individualize each one that

you create. - Clothing and accessories – when cutting into

the fabric, you’re able to create a pattern for

sewing or making clothing and accessories like

bags and hats. - Cards and stationery – making your own

stationery is easy with a vinyl cutter and is ideal

for cutting on cardstock, paper, and other light

materials too.

In terms of professional grade vinyl cutters, these

are commonly found in any industry that uses a

sign printer. When buying a vinyl cutter for a

larger scale use like this, there may be different

specifications and features that you would deem

important.

How Does A Vinyl Cutter Work?

Although there are hundreds of different makes

and models of vinyl cutters, they all operate in the

same basic way. A vinyl cutter is made of a

computer system and a small blade, with the

computer dictating to the knife where to cut.

The material is fed into the device on the cutting

platform, and this is where the cut is performed.

Once done, the excess material is weeded or

removed, and the final image is printed. Designs

can either be programmed into the cutter or

uploaded using specialized software created for

the machine.

If you’ve never used a vinyl cutter before, there

are just a few simple steps to do so. For

beginners, it’s best to start with a simple project

such as making a sticker. Keep in mind, though,

that you should always refer to the owner’s

manual which comes with your vinyl cutter for

more accurate directions.

Find an image that you want to use as a sticker,

by either using the pre-programmed designs that

come with your vinyl cutter or creating your own.

Images can be made on several programs,

depending on what’s compatible with your

machine, and then saved as a JPEG file for

printing.

Open the software which came with your cutter

and import the image you’ve created. Make the

required changes to get it to the right size and

remove anything you don’t wish to print.

Load the vinyl you will use to cut into the

machine, being sure to insert it in line with

anything sensors that the vinyl cutter has. This is

to ensure its aligned correctly and will print the

right way. Press the rollers down onto the vinyl so

they have a firm grip on it, and check everything

is lined up by looking at the system’s display.

Once everything is ready to go, you can press the

‘cut’ button or corresponding button depending on

your machine. The cutter should move from side

to side and the vinyl will move back and forth,

indicating that it’s working. Once done, move the

vinyl carefully out of the machine and your design

will be ready to go.

Each machine will have their own set of

instructions for how to get the best use out of it,

however, most desktop vinyl cutters work this

way.

Once you get the hang of how to achieve

the best results, it will take no time at all to feed

through the vinyl and other materials and get the

perfect cut.

Important Specs And Features

If you’ve never shopped around for a vinyl cutter

before, it may be quite overwhelming when you

finally do. There are hundreds of different makes

and models available, and all with their own

unique pros and cons to the user.

- Size: There are two things to consider with the

size of your vinyl cutter to see which is right for

you. Firstly, the size of the machine itself will be

determined by how much space your home

workshop has. Secondly, the size of the cutting

area means how much material you can feed into

it. For larger jobs, you’ll want a device that can

work with around 25” or more. - Speed: The speed of a cutter determines how

fast it can cut, and this is usually measured in

millimeters per second. However, the speed of

the cut is not a determination on how precise it is,

so don’t consider this the most important feature

when shopping around. - Memory: The memory of the vinyl cutter’s

computer is responsible for storing past designs,

and sometimes holding the pre-programmed

patterns and designs that the manufacturer

uploaded. These devices can often connect with

a computer which can store the important details,

so it’s not always important. - Blade Force Or Pressure: The force and

pressure of the blade are important for

determining how precise the cut will be, and the

types of materials it works with. For home use,

the force isn’t as crucial as it would be for a

professional workshop cutter which is being used

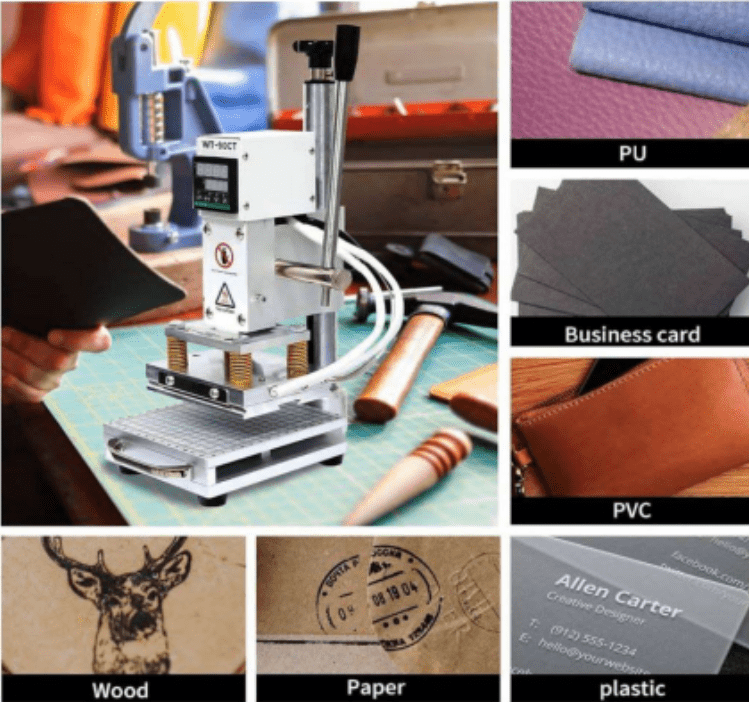

all day and for bulk projects. - Cutting Capabilities: The capabilities of a vinyl

cutter refer to the different materials and surface

it works with. Although called a vinyl cutter, these

machines are designed to cut through things like

fabric, tint, transfer material, cardstock, and

paper. However, always refer to the manual of

your specific machine to see what it works with

best. - Optic Eye: This is a laser pointing device that

allows your machine to contour cut. Contour

cutting is ideal for use with materials such as iron

on transfers, as it allows you to cut away the

excess and just leave you with what’s needed for

your design. This can give up to 0.1mm of

accuracy which makes it the most precise cut

available. - Scanner: Not every vinyl cutter comes with a

scanner inbuilt, however, most modern ones do.

This enables you to create a drawing which is

then scanned into the machine, and then used to

cut into the material of your choice. Scanners are

measured in terms of DPI which indicates how

high the resolution will be.

Ultimately, finding the best vinyl cutter for your

home workshop will depend greatly on the type of

projects you’ll be using it for. Someone who

makes signs and stickers professionally will have

different needs to someone who creates iron on

transfers for fun, so you should have a good idea

of your own requirements before you even begin

looking around.

USES OF A VINYL CUTTER

- Labels and Stickers: You can create

physical numbers or time labels, labels for

materials, supplies, and experiments, or even

glow in the dark safety labels. - Electronics: You can create acid resist

patterns for your custom PCBs, cut thin foil

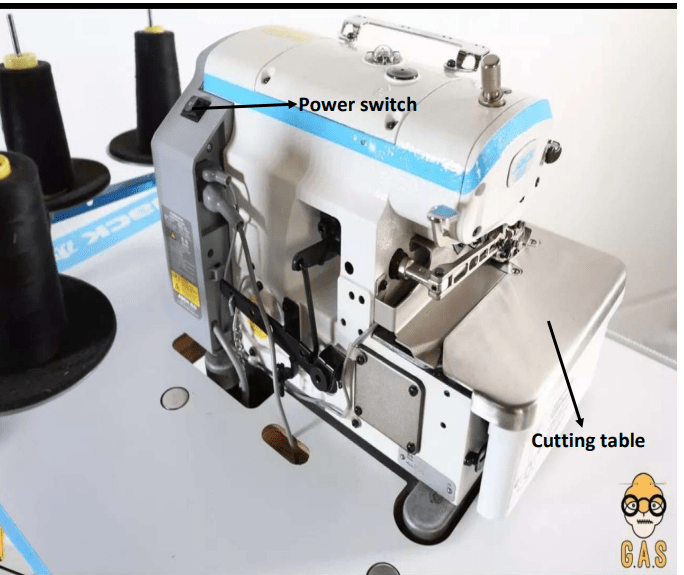

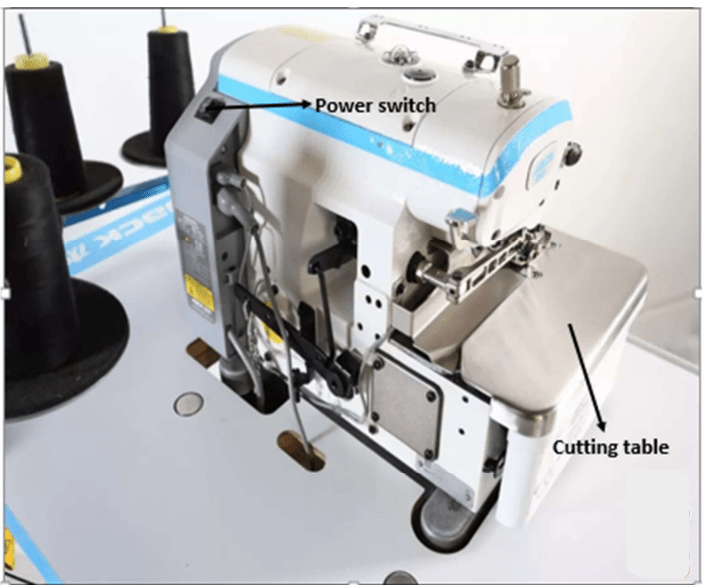

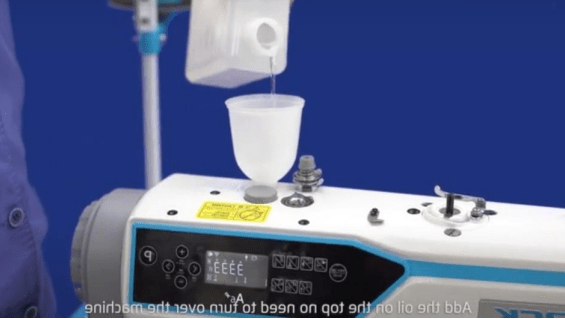

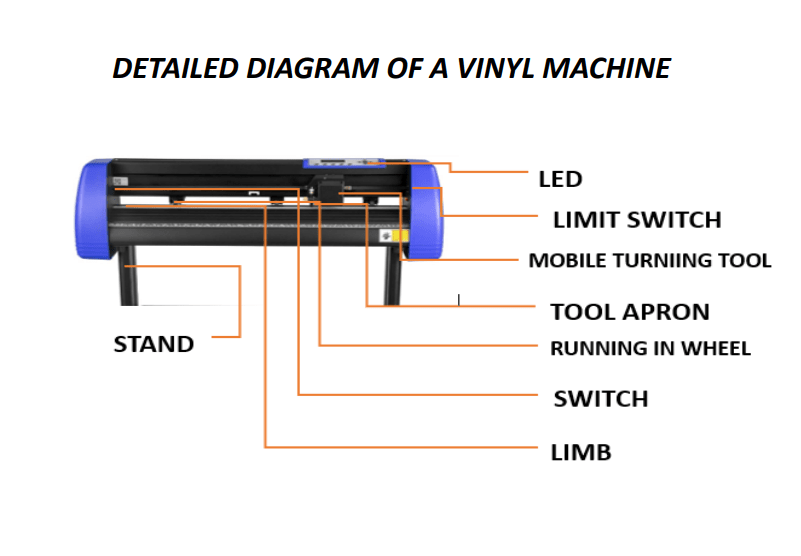

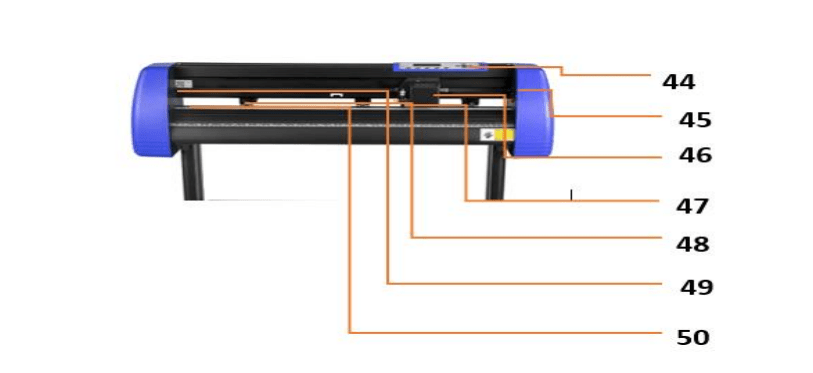

DETAILED DIAGRAM OF A VINYL MACHINE

traces, PCB layers, and RFF interference

protection for your paper circuits. - Woodworking, Craft, and Painting: You

can create and place trim markers on plywood,

MDF, acrylic, or hardwoods on-site, create edge

boundaries and resist patterns for painting,

staining, and coating, and prepare stencil vinyls

and plastic sheets suited to the specific water based or solvent-based paints you will be using. - Paper Engineering: You can cut, crease,

score, and perforate papers, cardstocks, and thin

plastics to create elaborate kirigami, origami, and

other paper craft projects. - Signs and Banners: You can create signs

and banners with a vinyl cutter. - T-shirt Designs: A vinyl cutter is a great

tool for creating custom t-shirt designs. - Wall Art: Vinyl cutters can be used to

create beautiful wall art that is both functional and

stylish. - Vinyl Mugs and Tumblers: You can use a

vinyl cutter to create designs on mugs and

tumblers.

MAINTENANCE FOR YOUR VINYL CUTTER

As a powerful machine that you’ve invested

money and time purchasing, you want to be sure

you’re caring for your vinyl cutter the best you

can.

Although most of them are covered by a

generous warranty, there are some things you

can do to ensure you get the most life out of them

and that they stay operating to the best of their

ability.

- Skipping Cuts & Perforated Lines: If you

notice errors in your cutting lines or if it seems

like the blade is skipping along your HTV leaving

your cut lines looking perforated, it might be time

to replace your cutter protection strip1 - Check the Cutter Protection Strip: The

strip, located across the length of the machine

where the blade cuts, protects the blade and

allows for a smooth pivot when cutting1

. Regularly

check this strip for any gashes, gaps, or divots. - Shallow or Deep Cuts: If you’re cutting

through the vinyl carrier even with proper force, or

if you see faint or missing cut lines completely,

make sure you have the blade depth set to a

specific standard. The blade should never extend

more than the width of a credit card below the

blade holder. - Consistent Blade Depth: Keeping the blade

depth consistent is important to protect your

blade and ensure complete cuts. - Rounded Corners: If you’re seeing rounded

cut corners rather than sharp, crisp edges, it

might be time to adjust the offset. The offset is

how the machine balances itself depending on

what blade you are using. - Preventive Measures: Keeping dirt off the

Vinyl Flooring is easier and less expensive than

removing it. - Regular Vacuuming: This is the most

important part of a successful maintenance

program. - Spill and Spot Cleaning: Spots are

inevitable, but they don’t have to be permanent.

Remove a spill quickly and there is less chance it

will become a stain. - Periodic Cleaning: Scheduled periodic

cleaning helps the Vinyl Flooring retain

appearance and improves performance. - Deep Cleaning: Seasonality can influence

the amount of cleaning required. Deep cleaning

will remove heavy soiling from within the emboss

structure and/or joints of the Vinyl Flooring. - Use of Rotary Flooring Machines: If using a

scrubbing machine, use only a slow speed (175

RPM) machine. Do not dry buff vinyl floors

without the use of a suitable finish coat.

SAFETY PRECAUTIONS TO BE TAKEN WHEN

USING A VINYL CUTTER

- Handle with Care: The device requires

installation and operation of this device requires

use of sharp blades. Caution should be taken to

make sure that fingers do not get caught in

moving gears during operation. - Power Management: Disconnect power

during assembly, service, and maintenance. - Avoid Static Build-up: Vinyl cutters are

subject to static build-up. Use of anti-static

devices including mats and anti-static vinyl

systems may be required in some environments. - Supervise Children: This vinyl cutter is not a

toy and should not be used by children without

supervision. - Avoid Magnetic Objects: Do not place any

magnetic objects in the vicinity of the cutting

head. - Manage Cables: Cables (mains power and

USB) could be a trip hazard for the operator or

those walking past the machine. - Avoid Injury: Never reach into the unit in the

vicinity of the blade holder during the cutting

operation. Discontinue any printing jobs in

progress before readjusting the blade holder. - Proper Storage: Always place the unit on a

stable base to prevent it from falling down. - Weather Conditions: Do not operate the unit

during thunderstorms; it can be damaged or

destroyed by lightning. - First Aid Kit: Ensure that a first aid kit is

available for minor cutting injuries. - Stable Workpiece: Ensure the item/object

being cut is stable to minimize the chances of

slipping.

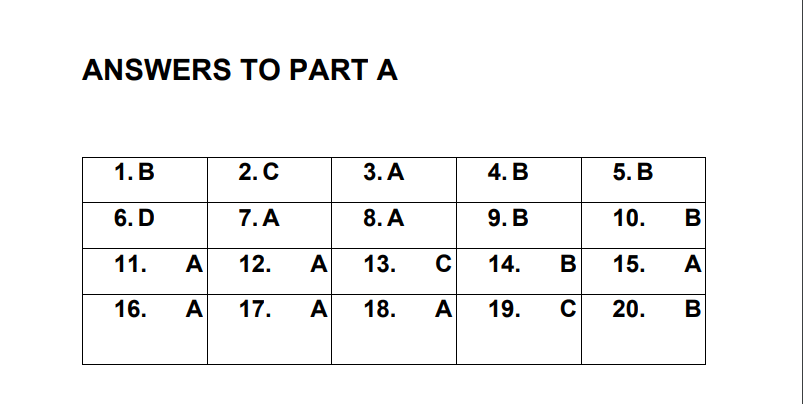

MULTIPLE CHOICE QUESTIONS

PART A:

CHOOSE THE CORRECT ANSWER

FROM THE OPTIONS.

- What is a vinyl cutter similar to in its

operation?

A) A sewing mach

B) A traditional printer

C) A typewriter

D) A photocopier - What does a vinyl cutter use to cut

patterns into materials?

A) Lasers

B) Heat

C) Small blades

D) Ink - When was the first instance of a vinyl

cutter invented?

A) 1888

B) 1901

C) 1923

D) 1955 - Who traditionally owned and operated

vinyl cutters?

A) Artists

B) Sign makers

C) Tailors

D) Carpenters - What is one reason vinyl cutters are

popular in home workshops?

A) They are inexpensive

B) They work well with a range of mediums

21

C) They are easy to clean

D) They require little maintenance - What can a basic home desktop vinyl

cutter achieve?

A) Iron on transfers

B) Stickers

C) Signs

D) All of the above - What is a vinyl cutter made of?

A) A computer system and a small blade

B) A large blade and a motor

C) A scanner and a printer

D) A laser and a cutting platform - What happens after the material is cut in

a vinyl cutter?

A) The excess material is weeded

B) The material is heated

C) The material is laminated

D) The material is scanned - What is one thing to consider when

shopping for a vinyl cutter?

A) The color of the machine

B) The size of the machine

C) The weight of the machine

D) The brand of the machine - What determines how fast a cutter can

cut?

A) The size of the machine

B) The speed of the cutter

C) The type of material being cut

D) The sharpness of the blade - What is the memory of the vinyl cutter’s

computer responsible for?

A) Storing past designs

B) Controlling the speed of the cutter

C) Determining the size of the cut

D) Powering the machine - What are the cutting capabilities of a

vinyl cutter?

A) Cutting through fabric

B) Cutting through metal and wood

C) Cutting through glass and ceramic

D) Cutting through leather and rubber - What is an optic eye in a vinyl cutter?

A) A device that measures the material’s

size

B) A device that controls cutter’s speed

C) A device that allows for contour cutting

D) A device that scans the material - What does a scanner in a vinyl cutter

do?

A) It scans the material after cutting

B) It scans a drawing

C) It scans the blade

D) It scans the machine for malfunctions. - What is one project a beginner can start

with when using a vinyl cutter?

A) Making a sticker

B) Creating a sign

25

C) Designing a logo

D) Cutting fabric for clothing - What is one way to find an image to use

as a sticker with a vinyl cutter?

A) Using the pre-programmed designs

B) Drawing the image by hand

C) Taking a photograph

D) Downloading an image from the internet - What should you do before pressing the

‘cut’ button on your vinyl cutter?

A) Check everything is lined up.

B) Clean the machine.

C) Replace the blade.

D) Turn off the machine. - What is one thing you should always

refer to when using a vinyl cutter?

A) The owner’s manual

B) The warranty card

C) The user reviews

D) The product brochure - What is one feature that may be

important when buying a vinyl cutter for

larger scale use?

A) The color of the machine

B) The brand of the machine

C) Different specifications and features

D) The weight of the machine - What does the size of the cutting area in

a vinyl cutter mean?

A) How much space the machine takes up

B) How much material you can feed into it

C) How large the machine is

D) How heavy the machine is.

PART B:

FILL THE GAP WITH THE

APPROPRIATE ANSWER.

- A vinyl cutter can be used to create

physical numbers or time labels, labels for

materials, supplies, and experiments, or

even ___________. - In electronics, a vinyl cutter can create

acid resist patterns for your custom

____________, cut thin foil traces, PCB layers,

and RFF interference protection for your

paper circuits. - A vinyl cutter can create and place trim

markers on ___________, MDF, acrylic, or

hardwoods on-site. - With a vinyl cutter, you can cut, crease,

score, and perforate papers, cardstocks,

and thin plastics to create elaborate

_____________, origami, and other paper craft

projects. - A vinyl cutter is a great tool for creating

custom ______________designs. - Vinyl cutters can be used to create

beautiful ______________ that is both functional and

stylish. - You can use a vinyl cutter to create

designs on mugs and ___________. - If you notice errors in your cutting lines

or if it seems like the blade is skipping along

your HTV leaving your cut lines looking

perforated, it might be time to replace your

______________. - The blade should never extend more

than the width of a __________below the blade

holder. - If you’re seeing rounded cut corners

rather than sharp, crisp edges, it might be

time to adjust the ____________. - Keeping dirt off the Vinyl Flooring is

easier and less expensive than ___________. - Spots are inevitable, but they don’t have

to be permanent. Remove a spill quickly

and there is less chance it will become a

______________. - Deep cleaning will remove heavy soiling

from within the emboss structure and/or

joints of the ______________. - If using a scrubbing machine, use only a

slow speed (_____________ RPM) machine. - The device requires installation and

operation of this device requires use of

_____________. - Vinyl cutters are subject to static buildup. Use of anti-static devices including mats

and anti-static vinyl systems may be

required in some ______________. - Do not place any ___________objects in the

vicinity of the cutting head. - Cables (mains power and USB) could

be a ___________hazard for the operator or

those walking past the machine. - Always place the unit on a stable

_____________to prevent it from falling down. - Ensure that a first aid kit is available for

minor ____________injuries.

MENTION THREE SAFETY

PRECAUTIONS TO BE TAKEN WHEN

USING A VINYL CUTTER MACHINE.

41. —————————————————————

42. —————————————————————

43. —————————————————————

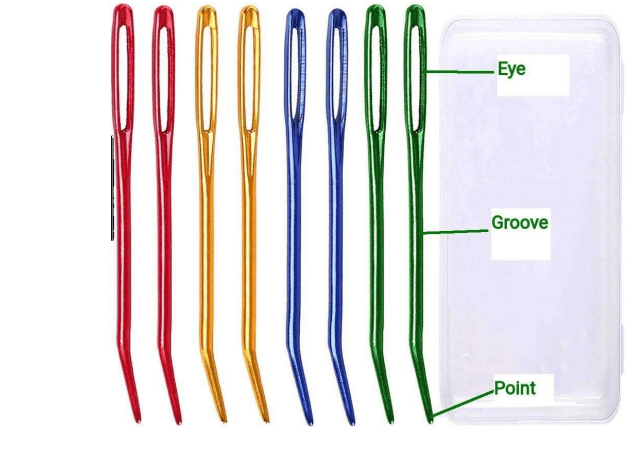

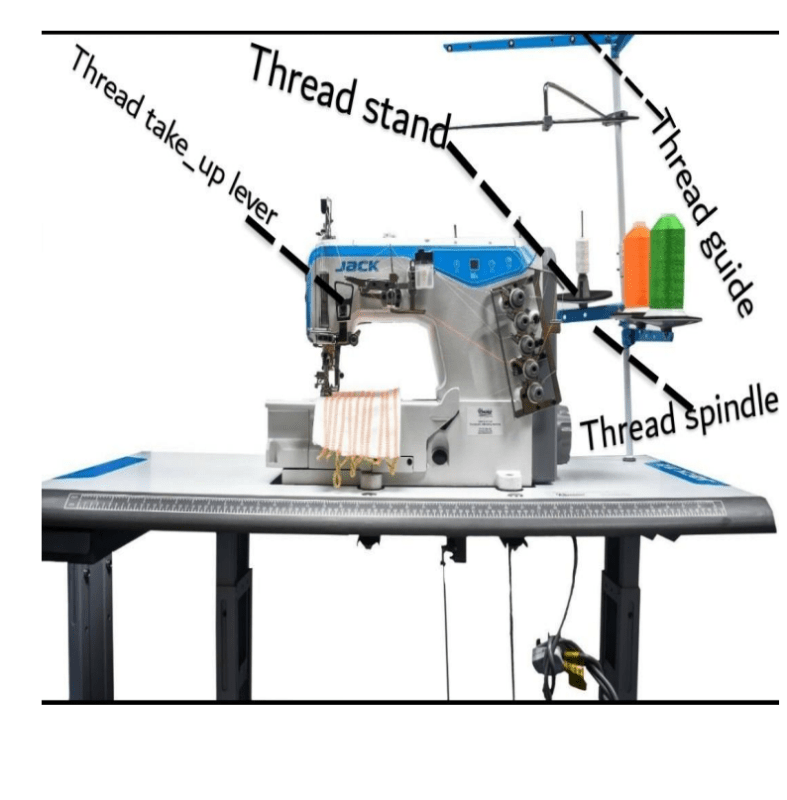

PART C:

FIND THE MISSING PARTS IN THE

DIAGRAM

44. ——————————————————-

45. ——————————————————–

46. ——————————————————–

47. ———————————————————

48. ———————————————————

49. ———————————————————

50. ———————————————————-

INSTRUCTORS COPY

ANSWERS TO PART B

- GLOW IN THE DARK SAFETY LABELS

- PCBS

- PLYWOOD

- KIRIGAMI

- T-SHIRT

- WALL ART

- TUMBLERS

- CUTTER PROTECTION STRIP

- CREDIT CARD

- OFFSET

- REMOVING IT.

- STAIN.

- VINYL FLOORING

- 175

- SHARP BLADES

- ENVIRONMENTS

- MAGNETIC

- TRIP

- BASE

- CUTTING.

- HANDLE WITH CARE

- POWER MANAGEMENT .

- AVOID STATIC BUILD-UP

ANSWER TO PART C

- LED

- LIMIT SWITCH

- MOBILE TURNING TOOL

- TOOL APRON

- RUNNING IN WHEEL

- SWITCH

- LIMB.