Blog

INTERLOCK SEWING MACHINE

21 minute read

Connect your mind!

Introduction

A sewing machine is a machine used to sew

fabric and materials together with thread.

Sewing machines were invented during the first

Industrial Revolution to decrease the amount of

manual sewing work performed in clothing

companies.

Since the invention of the first sewing machine,

generally considered to have been the work of

Englishman Thomas Saint in 1790,

the sewing machine has greatly improved the

efficiency and productivity of the clothing

industry.

1 https://en.wikipedia.org/wiki/Sewing_machine#cite_note-1

Home sewing machines are designed for one

person to sew individual items while using a

single stitch type at a time.

In a modern sewing machine, the process of

stitching has been automated, so that the fabric

easily glides in and out of the machine.

Early sewing machines were powered by either

constantly turning a flywheel handle or with a

foot-operated treadle mechanism.

Electrically-powered machines were later

introduced. Industrial sewing machines, by

contrast to domestic machines, are larger,

faster, and more varied in their size, cost,

appearance, and tasks.

The interlock sewing machine, generally known

as an eggbeater, is also known as a special

sewing machine, which produces a chain

sewer.

This sew is substantially used for knitted

products similar to rolled collars, pipelines,

and home cloth products similar to folded

edges, tense seams, spliced seams, and trims.

In recent times, there are so numerous different

styles of garments that a small sewing process

can be played out in a thousand different ways.

The Interlock sewing machine simplifies the

sewing process, making it more efficient and

versatile.

It allows for customization according to the

specific needs of a project, enabling

manufacturers to offer personalized, high-end

services.

The stitch made by an interlock sewing

machine is called an Interlock stitch, An

interlocking stitch is a type of stitch most

commonly used in garments made of knit fabric.

This stitch helps keep the fabric from stretching

out of shape and creates a tight seam.

The interlock stitch looks very similar to a

zigzag stitch, but the inside of the zigzag is

much narrower.2

TYPES OF AN INTERLOCKING SEWING

MACHINE

- VG-8 Series Super High-Speed MultiModule Cylinder Bed Interlock Stitch

Machine with Active Thread Control:

(a) Ideal for various difficult sewing conditions.

(b) Ensures high quality and investment efficiency.

(c) Features Yamato’s signature Active Thread

Control and an epoch-making multi-module

design. - VGS-8 Series Cylinder Bed Interlock

Stitch Machine with Top Feeder:

(a)Unique rear pivot top feeder.

(b) Active Thread Control and Yamato Non-Stain

Technology.

(c) Suitable for various sewing factory applications. - VE-8F Series High-Speed Small Cylinder

Bed Interlock Stitch Machine:

(a) Active Thread Control System.

(b)Differential feed dogs installed in a 180 mm

cylinder.

(c) Applicable for small tubular articles like cuffs,

necklines, and ankles. - VES-8F Series Small Cylinder Bed

Interlock Stitch Machine with Variable Top

Feeder:

(a) Combines a 180 mm cylinder with differential

feed mechanism.

(b) Ideal for small tubular articles.

(c) Provides easy material handling and neat

finishes. - VF2500-8 Series Super High-Speed Flat

Bed Interlock Stitch Machine:

(a)Supports microfibers.

(b)Active Thread Control for a wide range of

seams.

(c) Minimizes the risk of oil stains. - VFS2500-8 Series Flat Bed Interlock

Stitch Machine with Top Feeder:

(a) Avoids sewing slippage, ply shifts, or puckering.

(b) Combines Active Thread Control and a top

feeder.

(c) Minimizes the risk of oil stains. - VC2700G-8F Class High-Speed Cylinder

Bed Interlock Stitch Machine:

(a) Non-Stain Technology.

(b) Suitable for a wide range of sewing conditions.

Mkl..ll.l - VC2790G-8F Class 2,3 Needle Streamline

Cylinder Bed Interlock Stitch Machine:

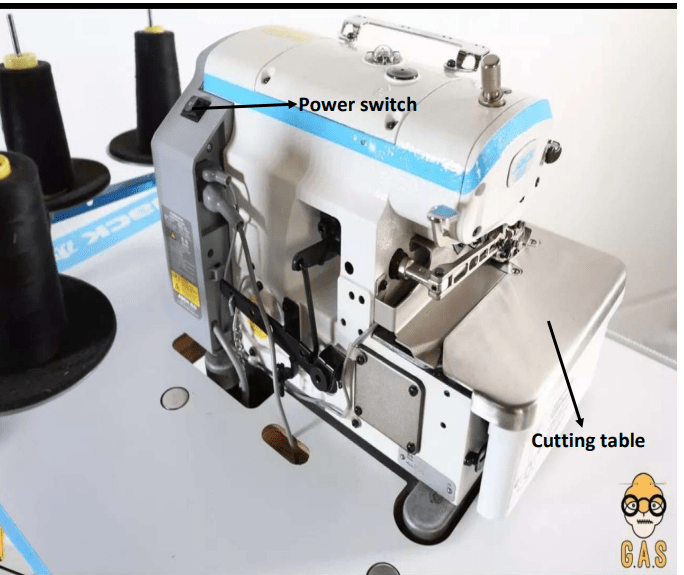

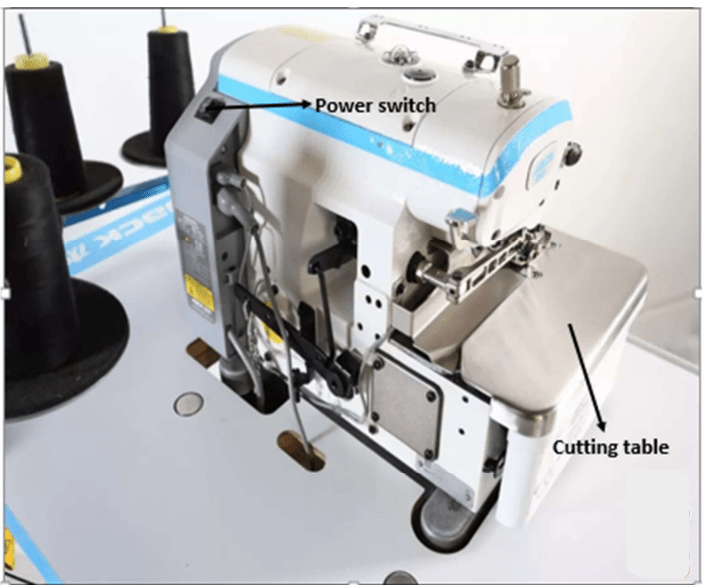

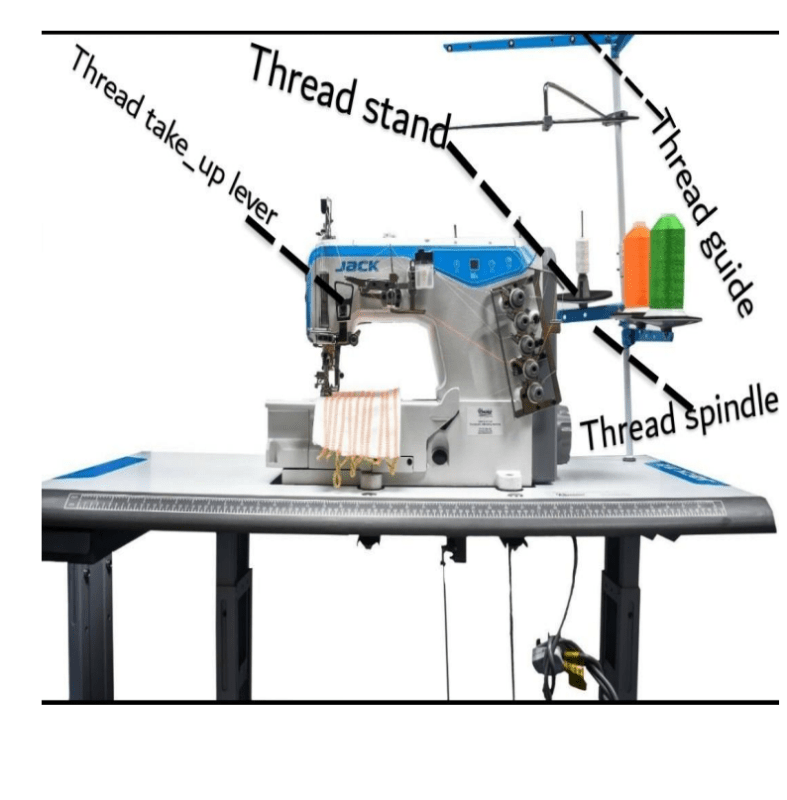

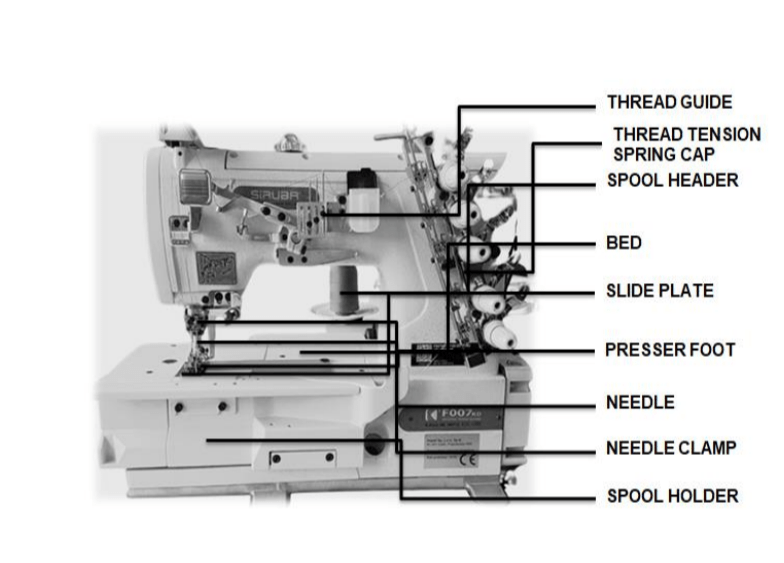

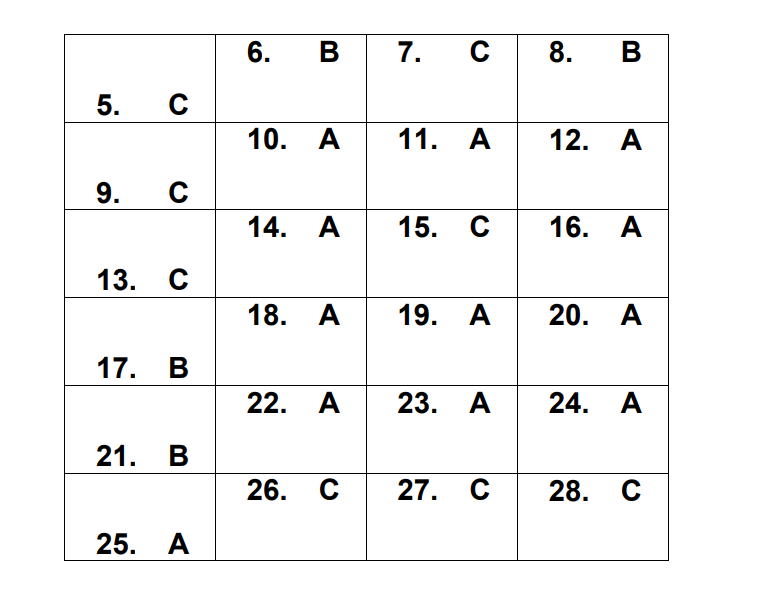

A WELL DETAILED DIAGRAM OF AN INTERLOCKING

SEWING MACHINE

SPECIFIC USES OF AN INTERLOCKING

SEWING MACHINE

An interlocking machine said earlier is a special

sewing machine has its own special uses, they

are:

11

- Rolled Edge Sewing: The interlocking

sewing machine can be used to neatly finish

the raw edges of fabric pieces, for example

using a 602 (two-needle, four-threaD) or

605 (three-needle, five-threaD) stitch can

reduce the bulkiness of seam allowances,

making the garment more comfortable to

wear.

By adjusting the machine, you can switch

between different stitch types like 406 (twoneedle, three-threaD) or 407 (threeneedle, four-thread), depending on the

desired finish and fabric thickness.

To do a rolled edge sewing, use the pack of

strips to wrap the raw edges of the cut

pieces for sewing, if you use a light pipeline,

the number of layers of sewing material on

the confluence allowance is too numerous,

and too thick, similar body-cut clothes may

not be comfortable to wear, but if you apply

the interlock sewing machine sewing 602

(two- needle, four- thread confluence

allowances) or 605( three- needle, fivethread confluence allowances) aches, the

pack of strips of raw edges of the package,

the number of layers of sewing material on

the confluence allowance can be reduced

from five layers to three and also can be

used for 406 ( two- needle, three- thread

confluence allowance) or 406( two- needle,

three- thread confluence allowance) aches.

The number of layers of material on the

confluence allowance can be reduced from

five to three, and 406(two-needle, threethread interlock sewing) or 407(threeneedle, four-thread interlock sewing) sew

can also be used (by removing the

ornamental vestments covering the interlock

machine, the 602 sew can be changed to

the 406 sew).

It is equipped with a sewing aid for a

pipeline, which not only reduces the

consistency of the confluence allowance but

also improves the effectiveness of the

operation. - Alternate Over locking and Sewing:

This technique involves using the interlock

machine to create a flat, smooth seam

allowance after over locking.

After the knitted garment is darned with over

lock sew, the confluence portion of the

confluence allowance won’t fit well because

of the pooching confluence portion, also the

confluence portion can be covered with the confluence allowance to make the

confluence portion fit well.

The pooching part of the confluence can be

made to fit, but the operation of this process

is frequently equipped with a special needle

plate and presser bottom to fix the

confluence allowance to make the operation

more controllable.

Because of the range between the two or

three aches of the tense sew, another netlike sew can cover the lace tape recording

and suture directly to the confluence

allowance on the cut piece.

And don’t need to fold the edge of the cut

piece to help loose edges, which can

reduce the consistency of the confluence

allowance, more comfortable to wear, similar to women’s knitted undergarments

with this system of sewing.

Special needle plates and presser feet may

be used to control the fabric and ensure a

neat finish.

- Sewing Process of Sole Lace: The

interlock machine allows for decorative

stitching over lace tape, attaching it directly

to the seam allowance without the need for

edge folding.

This reduces bulk and enhances comfort,

especially in garments like women’s knitted

undergarments. - Folded-Edge Stitching Process: For

edges that require a thin, flat finish, such as

skirt hems or trouser legs, the interlock

machine can combine over locking and

single-fold sewing into one step.

This not only streamlines the process but

also prevents common issues like twisted

edges. - Stitching on Elastic Fabrics: Sequel

to the strength of the interlock stitch, it’s

ideal for working with knitted and/or elastic

fabrics, the machine can also add

decorative, net-like stitches to enhance the

visual appeal of garments like knitted T-shirts and sweaters.

MAINTENANCE OF AN INTERLOCKING

SEWING MACHINE

- Use Good Quality Needle and Thread:

Using high-quality thread and needles is

crucial for the smooth operation of your

sewing machine.

Low-quality thread can be linty and harmful

to machines.

It’s recommended to change your needle

every 10 hours of active stitching or about

four bobbins worth of sewing.

This helps prevent stitch problems and

extends the life of your machine. - Don’t Use Canned Air for Cleaning:

While canned air might seem like a quick

solution for cleaning, it can actually cause

harm.

Canned air introduces moisture into your

sewing machine, which can lead to rusting

and corrosion of the machine’s delicate

components over time. Instead of canned air, it’s recommended to use a nylon brush for cleaning.

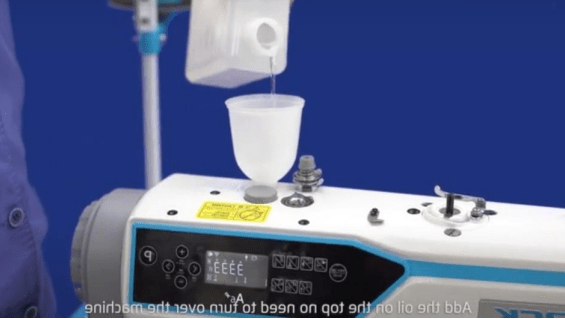

- Oil Your Machine Regularly: Oiling

your machine is essential for ensuring its

smooth operation and longevity.

Good quality sewing machine oil is

recommended.

The frequency of oiling can depend on how

often you use your machine.

If you use your machine daily, you should oil

it every day, if you use it less frequently, oil

it once a week.

- Cover Your Sewing Machine: To keep

your machine as clean as possible, store it

under a dust cover or in a hard case when

not in use.

This prevents dust, lint, and other particles

from accumulating in your machine, which

can affect its performance10. - Regular Cleaning: Regular cleaning is

crucial to prevent dust and lint buildup that

can clog the machine and affect its

performance.

A good rule of thumb is to clean and oil your

sewing machine once for every 5-10 days of

use.

- Tighten The Screws Regularly: Over

time, the screws of your sewing machine

may loosen.

Not only do loose screws make the sewing

process time-consuming, but they can also

lead to errors.

Hence, every now and then, keep tightening

the screws to make sure that the machine is

held properly. - Clean The Machine But Not All At

Once: It’s important to clean your machine

regularly, but not all at once.

This means you should clean one part at a

time to avoid confusion and ensure each

part is thoroughly cleaned.

SAFETY PRECAUTIONS TO BE TAKEN

WHEN USING AN INTERLOCKING SEWING

MACHINE

a. Turn Off and Unplug: It’s crucial to

turn off and unplug the sewing machine

after use.

This prevents accidental starts, which

could lead to injuries, and also ensures

that children or others won’t tamper with

the machine when it’s not being

monitored.

b. Keep Safe Distance: Keeping your

fingers at least an inch away from the

needle is a good practice.

This helps avoid accidental pricks or

getting your fingers caught under the

needle while feeding fabric through the

machine.

c. Use a Needle Guard: A needle guard is

a protective device that covers the

needle area.

It’s designed to prevent your fingers

from getting too close to the moving

needle, thus reducing the risk of injury.

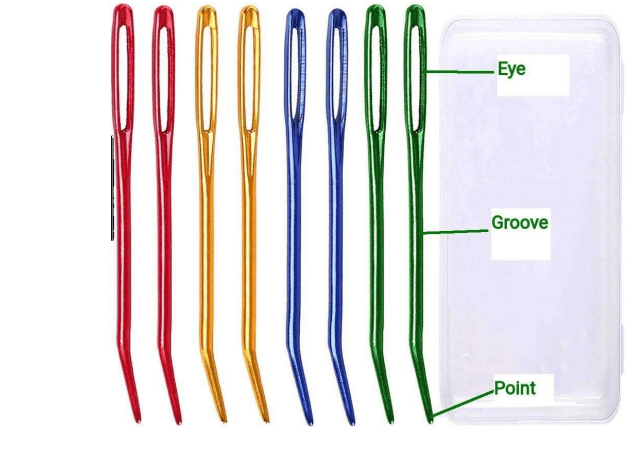

d. Secure Needles and Pins:

Organize and store needles, pins, and

pincushions in a sewing kit.

This not only keeps your workspace tidy

but also prevents these sharp objects

from causing accidental injuries.

e. De-clutter the Workspace: A

clutter-free workspace allows for better

concentration and reduces the risk of

mistakes that could lead to accidents.

Ensure that only the necessary tools are

on the table.

f. Inspect Needles: Always check that the

needles are straight and not damaged

before use.

Bent or broken needles can break

during sewing, potentially causing injury

or damaging the fabric.

g. Handle Sharp Objects Carefully:

Scissors, seam rippers, and other sharp

tools should be handled with care and

stored safely when not in use to prevent

cuts.

h. Avoid Sewing Over Pins:

Removing pins as you sew is important

because sewing over them can cause

the needle to break and possibly fly

towards you, which is dangerous.

i. Be Mindful of Hair: If you have long

hair, make sure to tie it back to prevent it

from getting caught in the machine’s

moving parts.

i. Proper Threading: Incorrect threading can

cause thread jams and needle breakage.

Make sure to thread the machine correctly

according to the manufacturer’s instructions.

j. Electrical Safety: Be cautious with the

sewing machine’s electrical components.

Avoid using the machine near water and

inspect cords for damage to prevent

electrical shocks.

k. Control the Fabric: Maintain control over

the fabric while sewing.

This helps prevent the fabric from pulling,

which can cause uneven stitches or needle

breakage.

MULTIPLE CHOICE QUESTIONS

PART A

- Who is generally considered to have

invented the first sewing machine?

A). Isaac Singer

B). Elias Howe

C). Thomas Saint

D). James Edward Allen Gibbs - What powers early sewing machines?

A). Solar energy

B). Battery

C). Constantly turning a flywheel handle or

with a foot-operated treadle mechanism

D). Wind energy - How do modern sewing machines differ

from early ones?

A). They are smaller

B). They are manually operated

C). The process of stitching has been

automated

D). They use different types of thread - What is another name for the interlock

sewing machine?

A). Eggbeater

B). Blender

C). Mixer

D). Whisk - What type of stitch does an interlock

sewing machine produce?

A). Straight stitch

B). Zigzag stitch

C). Interlock stitch

D). Over lock stitch - What is the interlock stitch most

commonly used in?

A). Garments made of woven fabric

B). Garments made of knit fabric

C). Leather products

D). Paper products - What does the interlock stitch help

prevent?

A). The fabric from fading

B). The fabric from tearing

C). The fabric from stretching out of shape

D). The fabric from shrinking - How does the interlock stitch look?

A. Similar to a straight stitch

B. Similar to a zigzag stitch, but the inside of

the zigzag is much narrower

C. Similar to an over lockstitch

D. Similar to a chain stitch. - What stitch can be used by the interlocking

sewing machine to reduce the bulkiness of

seam allowances?

A) 602 (two-needle, four-thread)

B) 605 (three-needle, five-thread)

C) Both a and b

D) None of the above - What does the interlock machine use to

improve the effectiveness of the operation in

rolled edge sewing?

A) Sewing aid for a pipeline

B) Special needle plate

C) Presser bottom

D) All of the above. - What is the purpose of the alternate over

locking and sewing technique?

A) To create a flat, smooth seam allowances

B) To cover the lace tape recording

C) To attach lace tape directly to the seam

allowance

D) None of the above. - What is used in the alternate over locking

and sewing technique to control the fabric and

ensure a neat finish?

A) Special needle plates and presser feet

B) Sewing aid for a pipeline

C) Both a and b.

D) None of the above. - What does the sewing process of sole lace

involve?

A) Decorative stitching over lace tape

B) Attaching lace tape directly to the seam

allowance without the need for edge folding

C) Both a and b

D) None of the above. - What does the folded-edge stitching

process prevent?

A) Twisted edges

B) Pooching confluence portion

C) Both a and b

D) None of the above. - What type of fabrics is the interlock stitch

ideal for working with?

A) Knitted fabrics

B) Elastic fabrics

C) Both a and b

D) None of the above. - What is recommended to use for cleaning

an interlocking sewing machine instead of

canned air?

A) A nylon brush

B) A cotton cloth

C) A feather duster

D) None of the above. - How often should you oil your sewing

machine if you use it daily?

A) Once a week

B) Every day

C) Once a month

D) None of the above. - What is recommended to store your sewing

machine under when not in use?

A) A dust cover or in a hard case

B) A plastic bag

C) A cardboard box

D) None of the above - How often should you clean and oil your

sewing machine?

A) Once for every 5-10 days of use

B) Once a week

C) Once a month

D) None of the above. - What should you do regularly to make sure

that the machine is held properly?

A) Tighten the screws

B) Oil the machine

C) Clean the machine

D) None of the above. - How should you clean your machine?

A) All at once

B) One part at a time

C) Both a and b

D) None of the above. - What is the purpose of using a 602 stitch in

rolled edge sewing?

A) To reduce the number of layers of sewing

material on the confluence allowance

B) To wrap the raw edges of the cut pieces

for sewing

C) Both a and b

D) None of the above. - What is the purpose of using a 605 stitch in

rolled edge sewing?

A) To reduce the number of layers of sewing

material on the confluence allowance

B) To wrap the raw edges of the cut pieces

for sewing

C) Both a and b

D) None of the above. - What is the purpose of using a 406 stitch in

rolled edge sewing?

A) To reduce the number of layers of sewing

material on the confluence allowance

B) To wrap the raw edges of the cut pieces

for sewing

C) Both a and b

D) None of the above. - What is the purpose of using a 407 stitch in

rolled edge sewing?

A) To reduce the number of layers of sewing

material on the confluence allowance

B) To wrap the raw edges of the cut pieces

for sewing

C) Both a and b

D) None of the above. - What is the purpose of the special needle

plate and presser bottom in the alternate over

locking and sewing technique?

A) To fix the confluence allowance

B) To make the operation more controllable

C) Both a and b

D) None of the above. - What is the purpose of the net-like sew in

the alternate over locking and sewing

technique?

A) To cover the lace tape recording

B) To suture directly to the confluence

allowance on the cut piece

C) Both a and b

D) None of the above. - What is the purpose of the folded-edge

stitching process?

A) To combine over locking and single-fold

sewing into one step

B) To streamline the process

C) Both a & b

D) None of the above.

PART B: Fill in the gap with the appropriate

answer

- The VG-8 Series is a __________

Interlock Stitch Machine with Active Thread

Control. - The VG-8 Series is ideal for ___________.

- The VGS-8 Series is a __________

Interlock Stitch Machine with Top Feeder. - The VGS-8 Series features___________

and Yamato Non-Stain Technology. - The VE-8F Series is a ___________

Interlock Stitch Machine. - Using high-quality thread and needles is

crucial for the smooth operation of your

sewing machine. Low-quality thread can be

__________ and harmful to machines. - Canned air introduces ___________ into your

sewing machine, which can lead to rusting

and corrosion of the machine’s delicate

components over time. - If you use your machine daily, you should oil

it __________. - To keep your machine as clean as possible,

store it under a ___________ or in a hard case

when not in use. - Over time, the screws of your sewing

machine may _________. Not only do loose

screws make the sewing process time consuming, but they can also lead to errors. - It’s important to clean your machine

regularly, but not all at once. This means you

should clean _________part at a time to avoid

confusion and ensure each part is thoroughly

cleaned. - It’s crucial to turn off and unplug the sewing

machine after use. This prevents accidental

starts, which could lead to _________, and also

ensures that children or others won’t tamper

with the machine when it’s not being

monitored. - Keeping your fingers at least an inch away

from the needle is a good practice. This helps

avoid accidental pricks or getting your fingers

caught under the needle while _________.

fabric through the machine - A needle guard is a protective device that

covers the needle area. It’s designed to

prevent your fingers from getting too close to

the moving needle, thus reducing the risk of

___________. - Organize and store needles, pins, and

pincushions in a sewing kit. This not only

keeps your workspace tidy but also prevents

these sharp objects from causing accidental

__________. - Always check that the needles are straight

and not damaged before use. Bent or broken

needles can break during sewing, potentially

causing injury or damaging the _____________. - Be cautious with the sewing machine’s

electrical components. Avoid using the

machine near water and inspect cords for

damage to prevent electrical ____________.

INSTRUCTORS COPY

ANSWERS TO MULTIPLE CHOICE

QUESTIONS 1-28.

ANSWERS TO FILL IN THE BLANK SPACES

- SUPER HIGH-SPEED MULTI-MODULE

CYLINDER BED - VARIOUS DIFFICULT SEWING

CONDITIONS - CYLINDER BED

- ACTIVE THREAD CONTROL

- HIGH-SPEED SMALL CYLINDER BED.

- LINTY

- MOISTURE

- EVERY DAY

- DUST COVER

- LOOSEN

- ONE

- INJURIES

- FEEDING

- INJURY

- INJURIES

- FABRIC

- SHOCKS

PART C: FIND THE MISSING PARTS IN THIS

DIAGRAM

- ————————————————-

- ————————————————-

- ————————————————-

- ————————————————-

- ————————————————-