20 minute read

introduction

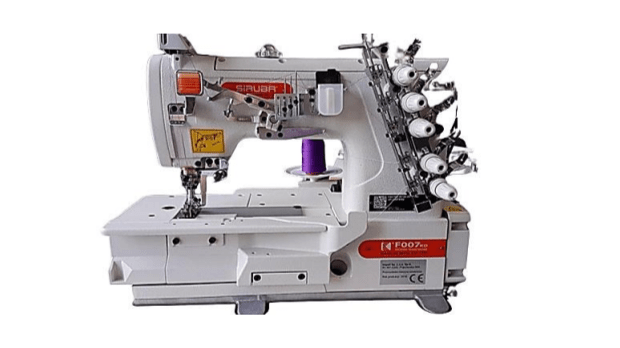

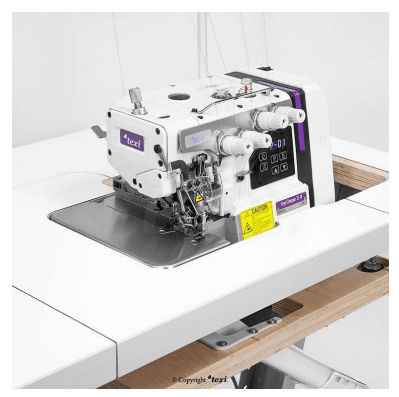

A 5-thread overlocking machine, often known as a

serger, is a sewing machine that uses five threads to stitch

fabric together while simultaneously trimming the edges

and preventing fraying.

This machine combines three overlocking threads

with two straight stitch threads, producing a secure,

professional seam.

The 5-thread overlocking machine is integral in both

industrial and high-quality home sewing settings.

This machine performs multiple functions in a single

pass, making it invaluable for efficiency and quality in

garment construction.

Its primary purpose is to create strong, durable seams and provide a clean finish by trimming excess fabric.

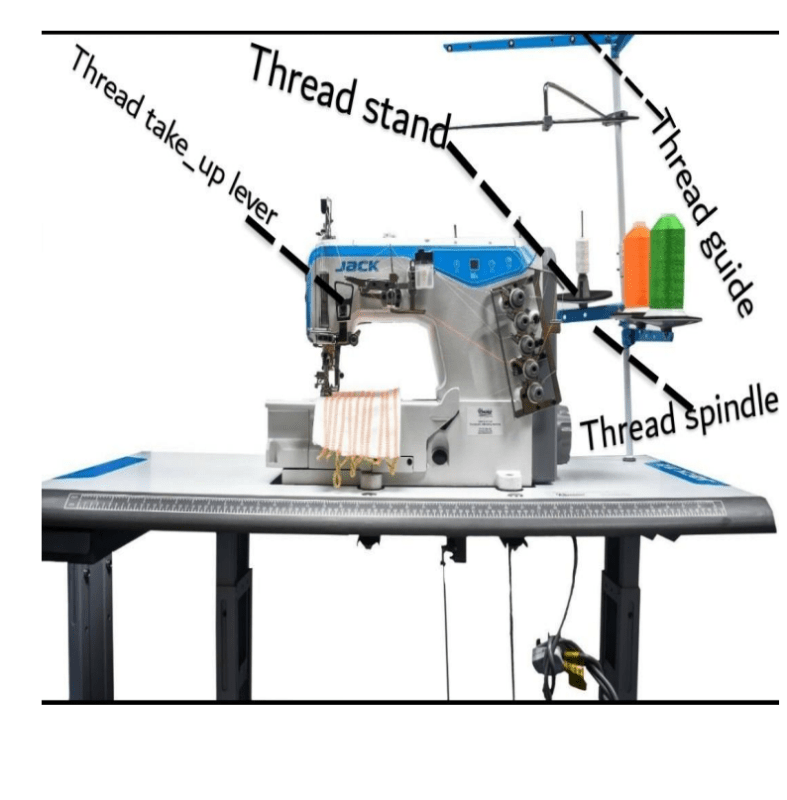

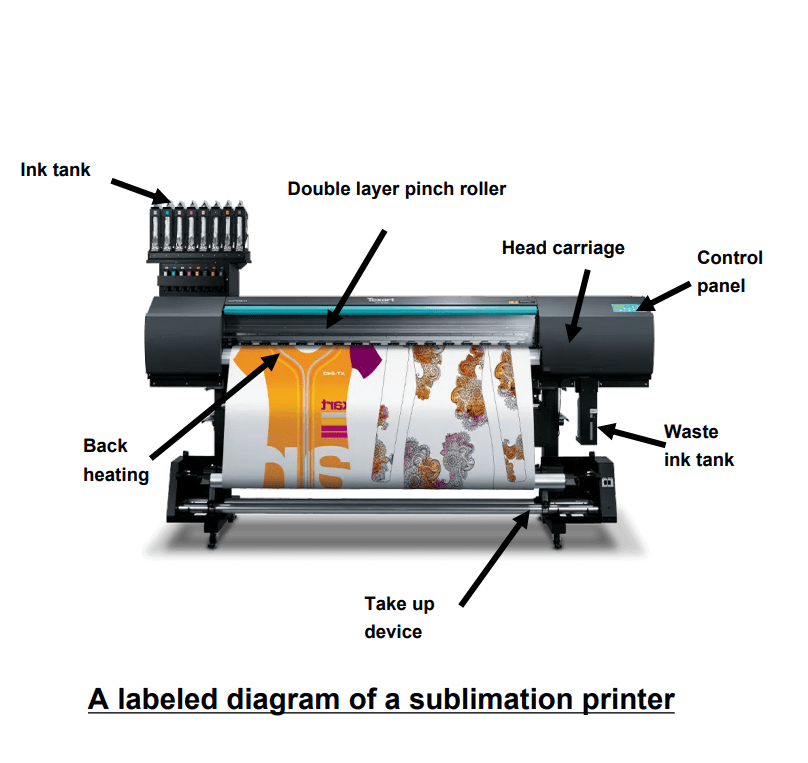

A Well-Detailed Diagram of a 5 thread

Overlocking Machine

Thread Tension Controls: Thread tension controls are

adjustable dials or knobs that regulate the tightness or

looseness of each thread.

Proper tension ensures even, balanced stitches and

prevents puckering or loose stitches where each thread

has its own tension control for precise adjustments.

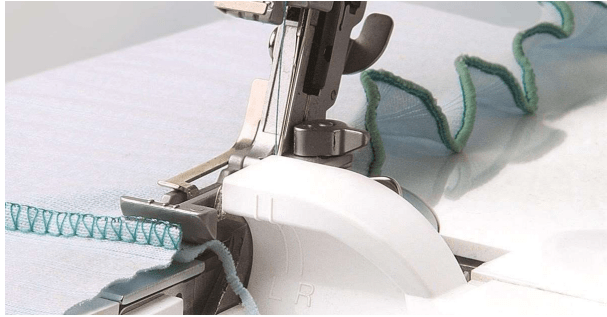

Blade: The blade, or cutter, trims excess fabric edges as

the machine sews, providing a clean, neat edge and

preventing fraying.

The blade works simultaneously with the stitching

mechanism to cut fabric just before the threads encase

the edge.

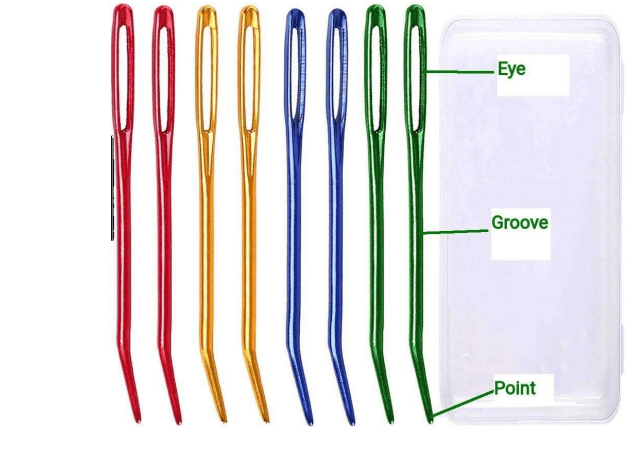

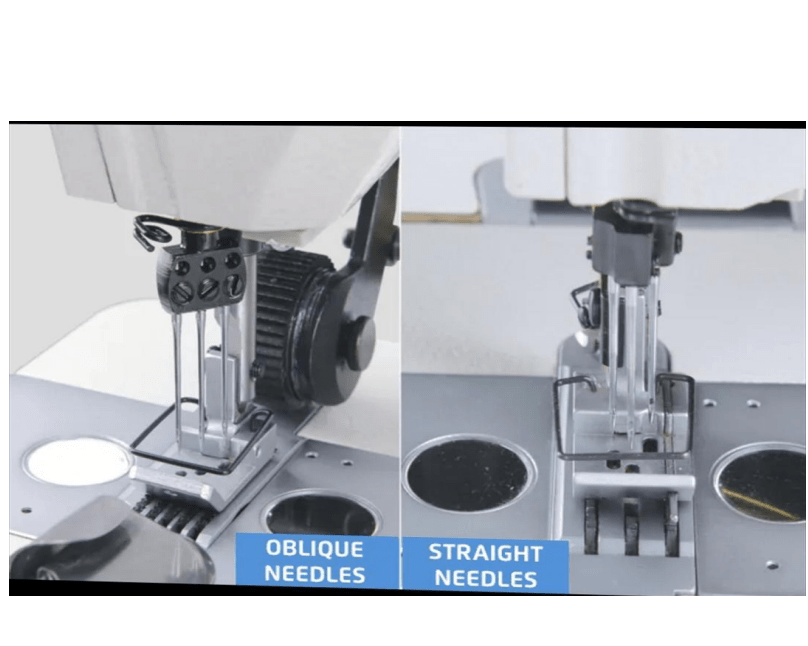

Needle/Presser Foot: The needles pierce the fabric to

create stitches, with 5-thread overlockers typically using

two needles for parallel stitching lines.

The presser foot holds the fabric in place and ensures it

feeds evenly through the machine which allows easy

positioning of fabric.

Scrap Fabric Catcher: The scrap fabric catcher collects

trimmed fabric scraps and thread clippings, keeping the

workspace clean and organized.

It is usually a detachable box or container and this helps

in easy disposal of waste material.

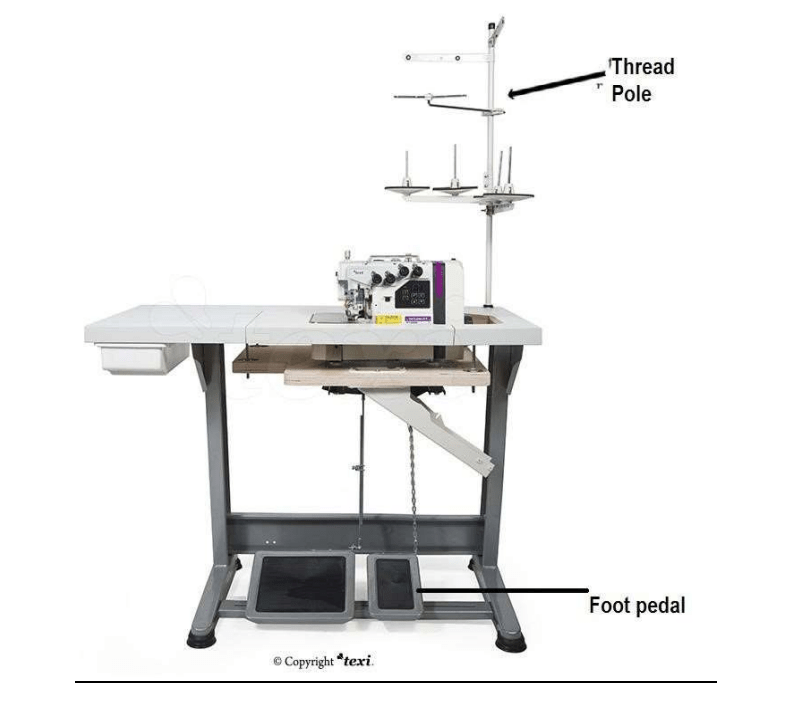

Thread Pole/Guide: The thread pole, or guide, is a vertical

stand that holds the spools of thread, ensuring smooth

and even thread feeding into the machine.

The thread pole helps prevent tangling and maintains

correct thread tension and also ensures smooth

operation.

Thread Holders (Behind): The thread holders are posts or

pegs at the back of the machine where spools of thread

are placed.

They keep the spools in position, allowing threads to be

pulled smoothly into the thread guides and tension

controls which maintains thread consistency.

Feed Dials/Presser Foot Lever: Feed dials adjust the

differential feed mechanism, controlling the fabric’s feed

rate to prevent stretching or puckering.

The presser foot lever raises or lowers the presser foot,

allowing easy fabric placement and removal.

Handwheel/Flywheel: The handwheel is a large wheel on

the side of the machine used to manually raise and lower

the needles and loopers.

It provides precise control over the needle position for

starting, threading, and maintenance tasks which is crucial

for accurate stitching.

A Full Diagram of the 5-thread overlocking

Machine.

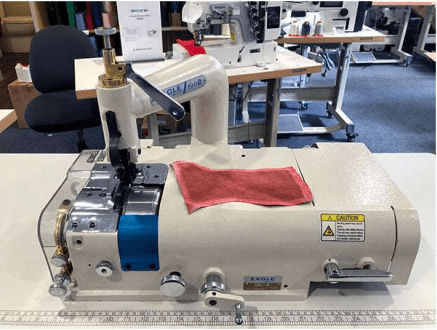

Variations of the Machine.

Standard 5-Thread Overlocker:

This is the basic model used for a wide range of sewing

tasks, including seaming, trimming, and finishing edges.

This variation of the 5-thread overlocking machine

provides robust and professional seams suitable for most

fabrics.

5-Thread Safety Stitch Overlocker:

Designed specifically for creating strong, durable seams

that are crucial in high-stress areas of garments.

This model is often used in the construction of

activewear and workwear, where seam strength is

paramount.

Differential Feed Overlocker:

This variation allows for more precise control over the

fabric feed, which is essential when working with stretchy

or delicate fabrics. The differential feed adjusts the

movement of the feed dogs to prevent fabric stretching

and puckering.

Specific Uses:

- Apparel Construction: Perfect for creating durable

seams in clothing, particularly in knitwear and stretchy

fabrics. - Home Decor: Used for finishing edges on items like

curtains, cushion covers, and table linens. - Quilting: Secures the edges of quilt pieces, ensuring

they don’t fray and stay intact.

- Crafts: Ideal for crafting projects that require neatly

finished edges and strong seams.

Benefits:

- Efficiency: Combines multiple functions—seaming,

trimming, and finishing—into one operation, saving time

and effort. - Professional Finish: Ensures a neat, clean edge, giving

garments and projects a polished look. - Durability: Produces strong, long-lasting seams that

are suitable for a variety of fabric types. - Versatility: Capable of handling different types of

fabrics, from delicate silks to heavy-duty denim. - Stretch Seams: Especially useful for knit fabrics, as it

allows seams to stretch without breaking.

Maintenance of the Machine

Maintaining a 5-thread overlocking machine is essential to

ensure its longevity and optimal performance. Here are

some key maintenance tasks:

- Regular Cleaning:

- Remove Lint and Dust: Frequently clean the machine

to remove lint and dust, which can accumulate and affect

performance.

Use a small brush or compressed air to clean out the

areas around the needles, loopers, and feed dogs. - Clean the Knife: The built-in knife can accumulate

fabric fibers so ensure it’s clean and sharp to maintain

precise cutting.

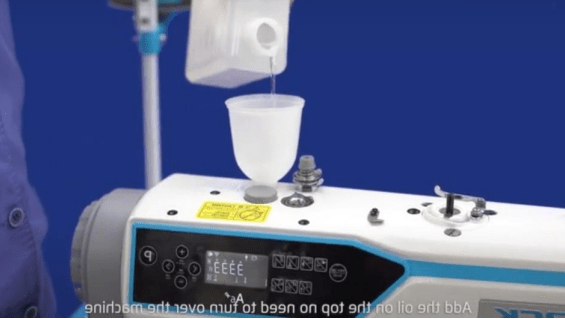

- Oiling:

- Lubricate Moving Parts: Regularly oil the moving parts of

the machine as per the manufacturer’s instructions.

Proper lubrication reduces friction and wear, ensuring

smooth operation.

- Needle Replacement:

- Change Needles Regularly: Over time, needles can

become dull or bent, so ensure they are regularly changed

to avoid skipped stitches and fabric damage.

- Threading:

- Correct Threading: Ensure the machine is threaded

correctly according to the user manual because incorrect

threading can lead to tension issues and poor stitch

quality.

- Tension Adjustment:

- Adjust Tension Settings: Regularly check and adjust the

tension settings to ensure even stitching while the whole

sewing process is going on

- Professional Servicing:

- Annual Servicing: Have the machine professionally

serviced at least once a year which involves having a

technician performing a thorough check-up and make

necessary adjustments or repairs.

Safety Precautions to be Taken When Using the

Machine

Using a 5-thread overlocking machine involves certain

safety risks, and it is crucial to follow safety precautions to

prevent accidents:

- Read the Manual:

- Understand Instructions: Thoroughly read and

understand the user manual before using the machine.

Familiarize yourself with all controls and features.

- Proper Lighting:

- Ensure Adequate Lighting: Work in a well-lit area to

clearly see the machine and fabric because this reduces

the risk of accidents and ensures precise sewing.

- Keep Fingers Away:

- Avoid the Needle and Knife: Keep fingers and hands

away from the needle and knife area while the machine is

in operation to avoid injuries.

- Use Safety Guards:

- Employ Guards and Shields: Ensure all safety guards and

shields are in place and properly used. These protect

against accidental contact with moving parts.

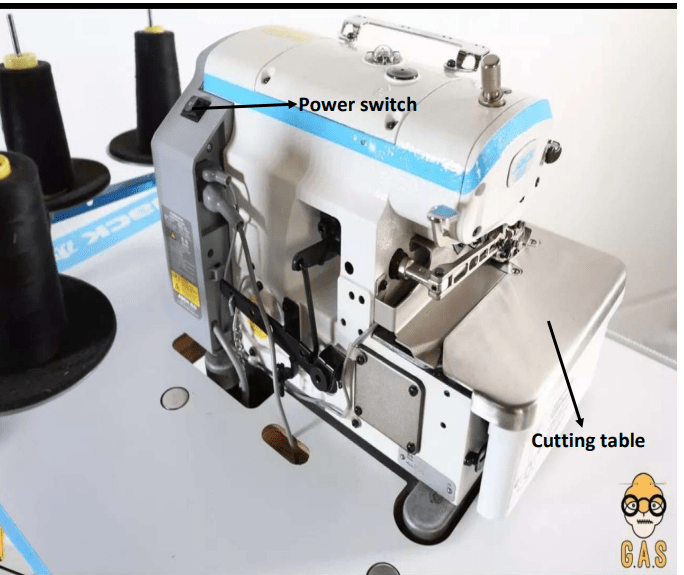

- Turn Off When Not in Use:

- Power Off: Always turn off the machine and unplug it

when not in use or when changing needles and threads.

This prevents accidental starts.

- Avoid Loose Clothing:

- Wear Appropriate Clothing: Avoid wearing loose

clothing, jewelry, or accessories that can get caught in the

machine.

- Regular Maintenance:

- Maintain Properly: Regularly maintain the machine to

ensure it operates safely because a poorly maintained

machine is more likely to malfunction and cause

accidents.

- Use the Right Needles and Threads:

- Appropriate Tools: Use the correct type and size of

needles and threads for the fabric you are working with.

This prevents damage to the fabric and machine.

- Keep the Area Clean:

- Organized Workspace: Maintain a clean and organized

workspace to avoid accidents caused by clutter or

misplaced tools.

- Emergency Procedures:

- Know Emergency Stops: Be aware of how to quickly stop

the machine in case of an emergency and always know

where the power switch and emergency stop are located.

Summary:

Fistly, A 5-thread overlocking machine, also known as a

serger, uses five threads to stitch fabric while

simultaneously trimming the edges and preventing

fraying.

It combines three overlocking threads with two straight

stitch threads to produce secure, professional seams,

making it essential in both industrial and high-quality

home sewing settings.

This machine’s primary purpose is to create strong,

durable seams and provide a clean finish by trimming

excess fabric, performing multiple functions in a single

pass for efficiency and quality in garment construction.

Furthermore, Key parts include thread tension controls,

which ensure even, balanced stitches by adjusting thread

tightness, and a blade that trims fabric edges while

sewing.

The needle/presser foot holds and guides fabric,

ensuring even feeding, while the scrap fabric catcher

keeps the workspace clean by collecting waste material.

The thread pole/guide holds spools and ensures smooth

thread feeding, and thread holders maintain thread

consistency.

Feed dials and the presser foot lever adjust the

differential feed and fabric placement, respectively, while

the handwheel allows manual control over needle

position for precise stitching.

Variations of the machine include the standard 5-thread

overlocker for general sewing tasks, the 5-thread safety

stitch overlocker for strong seams in high-stress areas, the

coverstitch machine for hemming and topstitching, and

the differential feed overlocker for precise fabric feed

control.

Specific uses of the machine range from apparel

construction, especially in knitwear and stretchy fabrics,

to home decor, quilting, and crafts.

Maintenance involves regular cleaning to remove lint

and dust, oiling moving parts, needle replacement,

correct threading, tension adjustment, and annual

professional servicing.

Safety precautions include reading the manual,

ensuring proper lighting, keeping fingers away from the

needle and knife, using safety guards, turning off the

machine when not in use, wearing appropriate clothing,

maintaining the machine, using the right needles and

threads, keeping the workspace clean, and knowing

emergency stop procedures.

Multi-choice Questions

Part A

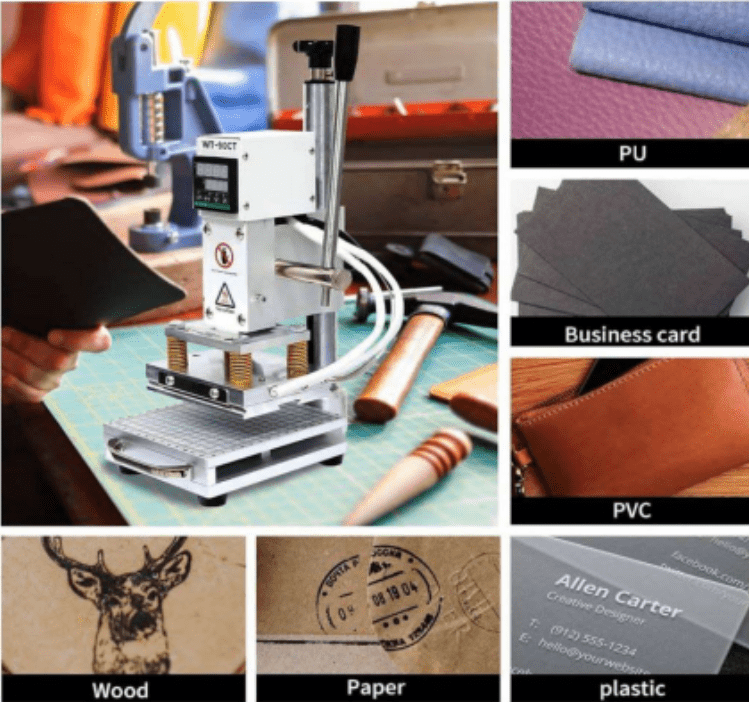

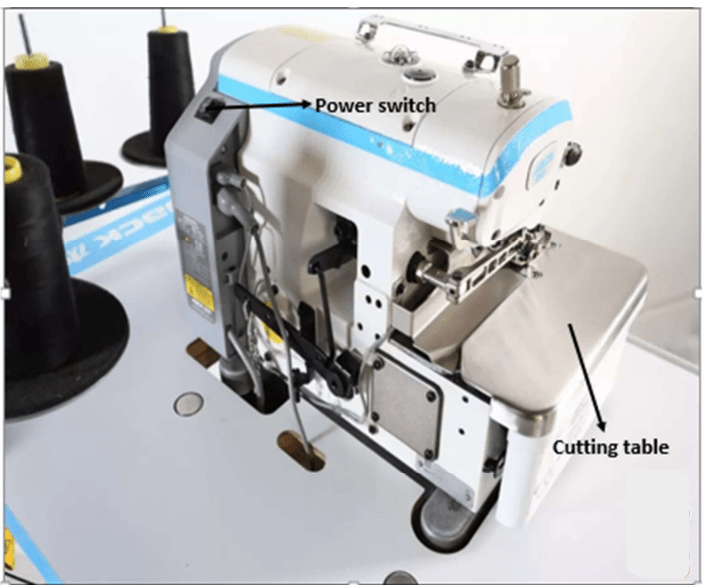

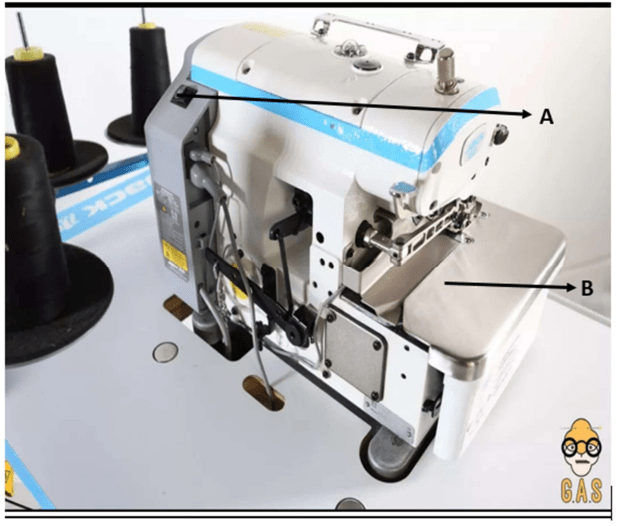

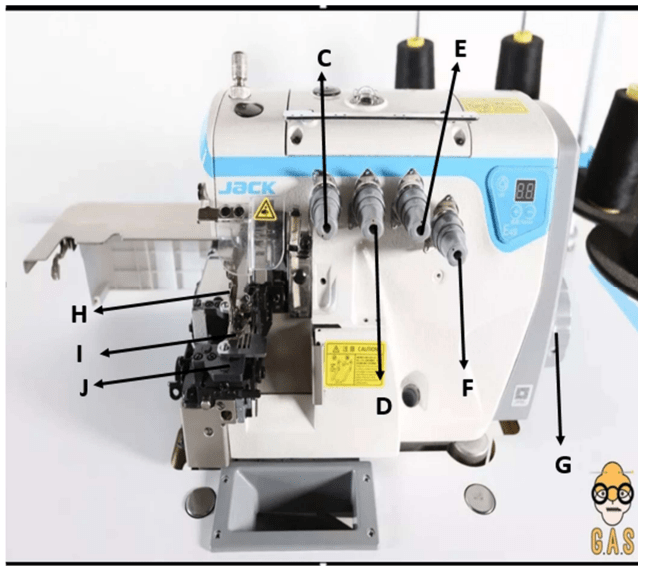

Using the diagram below answer questions 1-8 by naming the components labeled A-J

1.The component labeled A is known as _____________ A) Heat Resistant Handle B) Presser Foot C) Cooling Button D) Power Switch

2.The component labeled B is known as ____________

A) Flat board

B) Heating Tube

C) Cutting Table

D) Temperature control Board

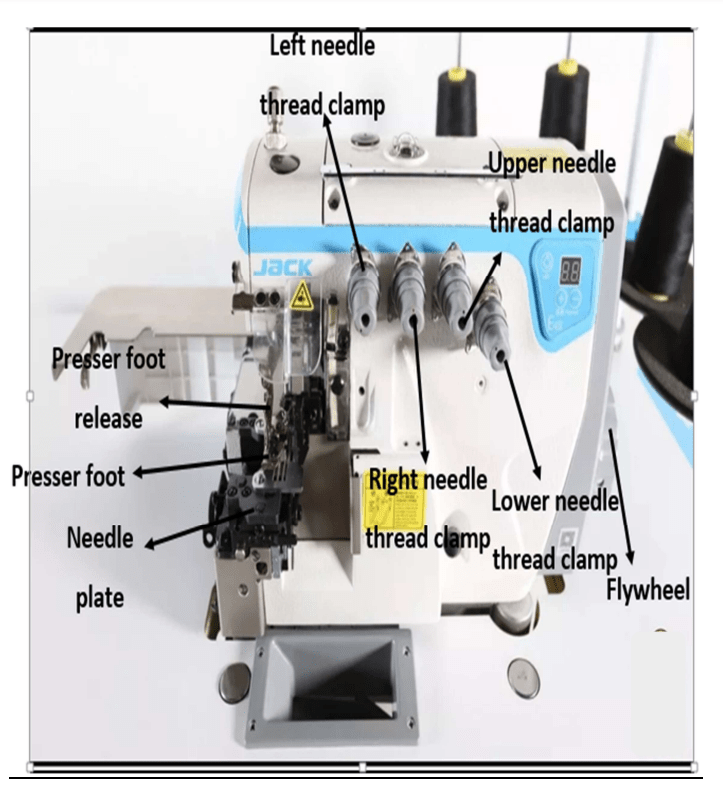

3.The component labeled C is known as _____________

A) Left Needle Thread Clamp B) Right Needle Thread Clamp C) Upper Needle Thread Clamp D) Lower Needle Thread Clamp

4.The component labeled D is known as _____________

A) Lower Needle Thread Clamp

B) Left Needle Thread Clamp

C) Upper Needle Thread Clamp

D) Right Needle Thread Clamp

- The component labeled E is known as ______________

A) Left Needle Thread Clamp

B) Upper Needle Thread Clamp

C) Lower Needle Thread Clamp

D) Left Needle Thread Clamp - The component labeled F is known as ____________A) Lower Needle Thread Clamp B) Upper Needle Thread Clamp C) Right Needle Thread Clamp D) Left Needle Thread Clamp

- The component labeled G is known as _____________

A) Flywheel

B) Rotary knob

C) Cooling circle

D) Temperature control - The component labeled H is known as ____________

A) Left Needle Thread Clamp

B) Rubber plate

C) Presser foot release button

D) Presser foot - The component labeled I is known as ___________

A) Presser foot release button

B) Flywheel

C) Cooling button

D) Presser foot - The component labeled J is known as ____________

A) Flywheel

B) Heating Tube

C) Presser foot

D) Needle plate - What is the purpose of the scrap fabric catcher?

A. Holds the spools of thread

B. Collects trimmed fabric scraps

C. Adjusts the differential feed

D. Raises or lowers the presser foot - The _____________part of the machine ensures

smooth and even thread feeding into the machine.

A. Thread tension controls

B. Blade

C. Handwheel

D. Thread pole/guide - What is the function of the feed dials?

E. Adjusting thread tension

F. Controlling fabric feed rate

G. Trimming excess fabric

H. Collecting trimmed fabric scraps - Which variation of the machine is designed for

creating strong seams in high-stress areas of garments?

A. Standard 5-Thread Overlocker

B. 5-Thread Safety Stitch Overlocker

C. Coverstitch Machine

D. Differential Feed Overlocker - What is one specific use of a 5-thread overlocking

machine?

A. Carpet weaving

B. Apparel construction

C. Metalworking

D. Plumbing - Which benefit is NOT associated with using a

5thread overlocking machine?

A. Efficiency

B. Durability

C. Stretch Seams

D. Embroidery capabilities - What is a key maintenance task for the machine?

A. Changing light bulbs

B. Sharpening scissors

C. Regular cleaning

D. Painting the machine - What is the recommended frequency for

professional servicing of the machine?

A. Monthly

B. Bi-annually

C. Annually

D. Every two years - What is the first safety precaution mentioned

when using the machine?

A. Keep fingers away from the needle and knife

B. Read the manual

C. Ensure adequate lighting

D. Turn off the machine when not in use - Why should you avoid loose clothing when

operating the machine?

A. To prevent fabric fraying

B. To ensure even stitching

C. To avoid accidents

D. To maintain proper tension - What should be done before using the machine

for the first time?

A. Clean the machine

B. Lubricate moving parts

C. Adjust tension settings

D. Read the user manual - What is the purpose of using safety guards and

shields?

A. To adjust thread tension

B. To prevent accidents

C. To collect trimmed fabric scraps

D. To lubricate moving parts - What is the consequence of incorrect threading?

A. Stretching fabric

B. Fabric fraying

C. Uneven stitches

D. Fabric shrinking - What should be done to ensure proper lighting?

A. Install additional lamps

B. Work in the dark

C. Use natural sunlight

D. Work in a well-lit area - What part of the machine holds the spools of

thread?

A. Handwheel

B. Thread pole/guide

C. Thread holders (behind)

D. Needle/presser foot - What is the purpose of the differential feed

overlocker variation?

A. Creating decorative stitches

B. Precise control over fabric feed

C. Quilting

D. Adjusting thread tension - Why is regular maintenance important for the

machine?

A. To make the machine louder

B. To ensure proper thread tension

C. To prevent accidents

D. To ensure longevity and optimal performance - What should be done before changing needles

and threads?

A. Turn off the machine

B. Lubricate moving parts

C. Adjust tension settings

D. Increase blade width - What is the purpose of the needle/presser foot?

A. Holds the fabric in place

B. Trims excess fabric edges

C. Collects trimmed fabric scraps

D. Holds the spools of thread - What is the consequence of not maintaining a

clean workspace?

A. Increased efficiency

B. Cluttered environment

C. Decreased risk of accidents

D. Improved thread tension

Part C:

Fill in the gap with the appropriate answers in the blank

spaces given below.

- A 5-thread overlocking machine, often known as

a ___________, is a sewing machine that uses five

threads to stitch fabric together while

simultaneously trimming the edges and

preventing fraying. - The machine combines three overlocking threads

with two ___________stitch threads, producing a

secure, professional seam. - The primary purpose of a 5-thread overlocking

machine is to create strong, durable ___________and

provide a clean finish by trimming excess fabric. - Thread tension controls are adjustable dials or

knobs that regulate the ________or looseness of

each thread. - The blade, or cutter, trims excess fabric edges as

the machine sews, providing a clean, neat edge

and preventing ____________. - The presser foot holds the fabric in place and

ensures it feeds evenly through the machine,

while the presser foot lever allows easy __________

of fabric. - The scrap fabric catcher collects trimmed fabric

scraps and thread clippings, keeping the

workspace clean and __________. - The thread pole, or guide, is a vertical stand that

holds the spools of thread, ensuring smooth and

even thread __________ into the machine. - The thread holders are posts or pegs at the back

of the machine where spools of thread are

placed, allowing threads to be pulled smoothly

into the thread guides and __________controls. - The feed dials adjust the differential feed

mechanism, controlling the fabric’s feed rate to

prevent ______________ or puckering. - The handwheel is a large wheel on the side of the

machine used to manually raise and lower the

needles and _____________. - The Standard 5-Thread Overlocker is the basic

model used for a wide range of sewing tasks,

including seaming, trimming, and finishing

_____________. - The 5-Thread Safety Stitch Overlocker is designed

specifically for creating strong, durable seams

that are crucial in high-stress areas of _____________. - The Coverstitch Machine uses a combination of

needle threads and looper threads to create

cover stitches, which are used for hemming and

_______________. - The Differential Feed Overlocker variation allows

for more precise control over the fabric feed,

which is essential when working with stretchy or

_____________ fabrics. - One specific use of a 5-thread overlocking

machine in home decor is for finishing edges on

items like curtains, cushion covers, and _________

linens. - A key benefit of using a 5-thread overlocking

machine is its __________, combining multiple

functions into one operation. - To ensure the longevity and optimal performance

of a 5-thread overlocking machine, regular

___________ is essential. - One important maintenance task is to frequently

clean the machine to remove ___________and dust. - To prevent accidents, always turn off the

machine and unplug it when not in use or when

changing ____________ and threads.

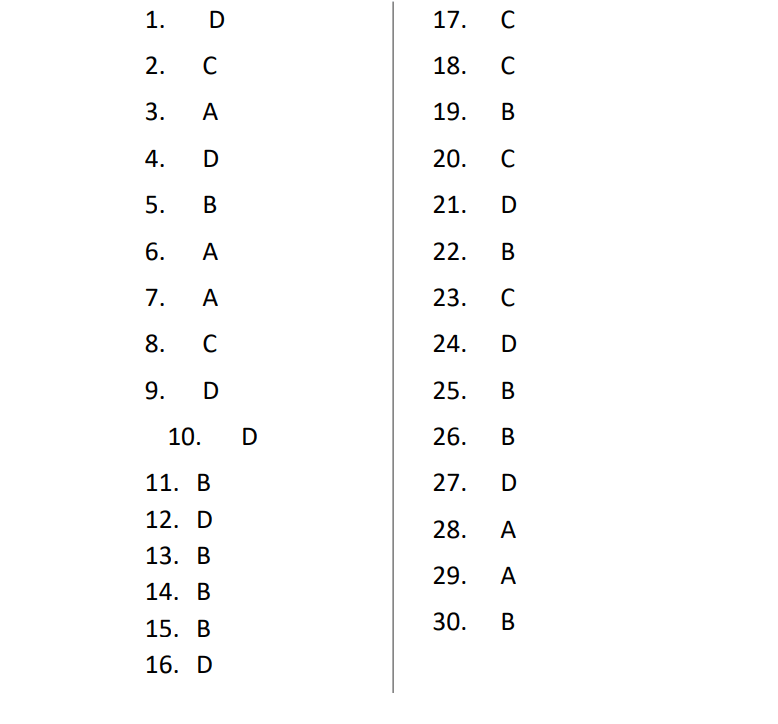

Instructors’ copy

Answers To Multiple Choice Questions 1-30

Answers To Fill In The Gap Question 31-50

- SERGER

- STRAIGHT

- SEAMS

- TIGHTNESS

- FRAYING

- POSITIONING

- ORGANIZED

- FEEDING

- TENSION

- STRETCHING

- LOOPERS

- EDGES

- GARMENTS

- TOPSTITCHING

- DELICATE

- TABLE

- EFFICIENCY

- MAINTENANCE

- LINT

- NEEDLES