30 minute read

Introduction

In the intricate world of sewing, the needle is a

fundamental tool that can significantly impact the quality

of your work.

Understanding the different types of needles and

their specific applications is essential for achieving precise

and professional results, this project focuses on three

types of specialized needles: Tapestry, Microtex, and

Beading needles.

Each of these needles has unique characteristics that

make them suitable for specific fabrics and stitching

techniques.

By exploring their uses, compatibility with various

sewing machines, and maintenance requirements, this

project aims to provide a comprehensive guide for sewing

enthusiasts and professionals alike.

Through detailed analysis and practical insights, we

will uncover how these needles contribute to the art and

efficiency of sewing, ensuring optimal performance and

longevity of both the needles and the sewing machines.

Brief Definition on the Sewing Machine it is Used

Upon

Sewing machines are designed for specific types of

stitching, each requiring particular needles to function

effectively.

This section provides an overview of various sewing

machines and identifies which of the specialized

needles—Tapestry, Microtex, and Beading—are

compatible with each machine.

Understanding the compatibility and specific uses of

these needles enhances the quality of sewing projects

and ensures optimal machine performance.

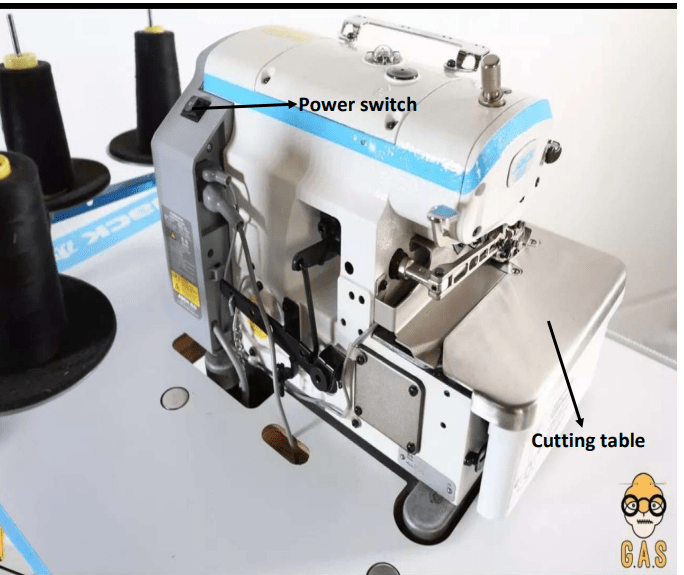

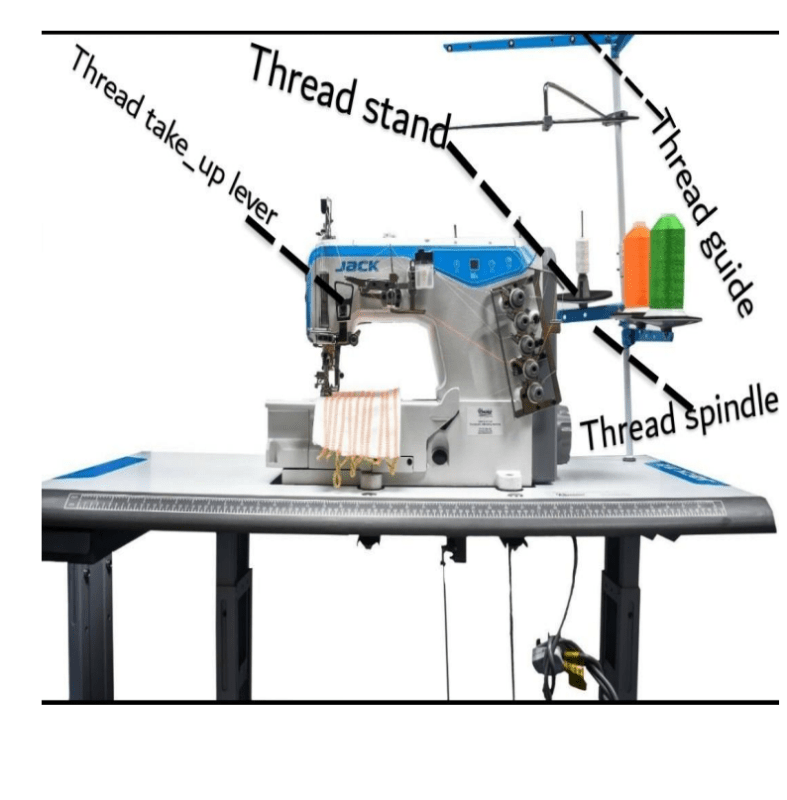

- 3 Thread Overlock Sewing Machine

- Function: Used to finish the edges of fabric to prevent

fraying, creating a narrow, strong seam suitable for

lightweight to medium fabrics. - Compatible Needle: This machine typically uses

standard overlock needles, tapestry, Microtex, and

Beading needles are not typically compatible with this

machine.

- 4 Thread Overlock Sewing Machine

- Function: Adds an additional thread for increased

durability and flexibility in seams, ideal for stretch and

knit fabrics.

• Compatible Needle: Uses robust overlock needles.

Tapestry, Microtex, and Beading needles are not usually

suitable for this machine.

- 5 Thread Overlock Sewing Machine

- Function: Combines an overlock stitch and a chain

stitch for a secure and robust seam, suitable for heavy

fabrics and multiple layers. - Compatible Needle: Heavy-duty overlock needles are

required. Tapestry, Microtex, and Beading needles are

not compatible with this machine.

- Lock Stitch Sewing Machine

- Function: The most common type of sewing machine,

used for straight stitches on a variety of fabrics.

Compatible Needle:

• Microtex Needles: Ideal for this machine, especially for

sewing fine or tightly woven fabrics due to their sharp,

slender point, they provide precise and clean stitches.

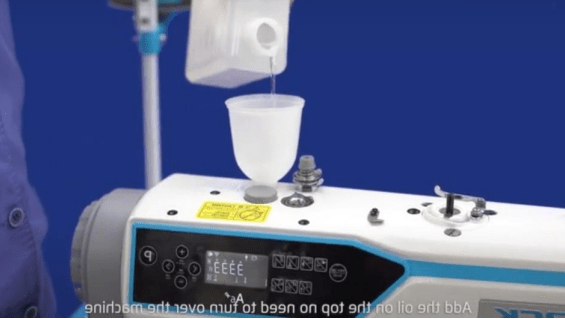

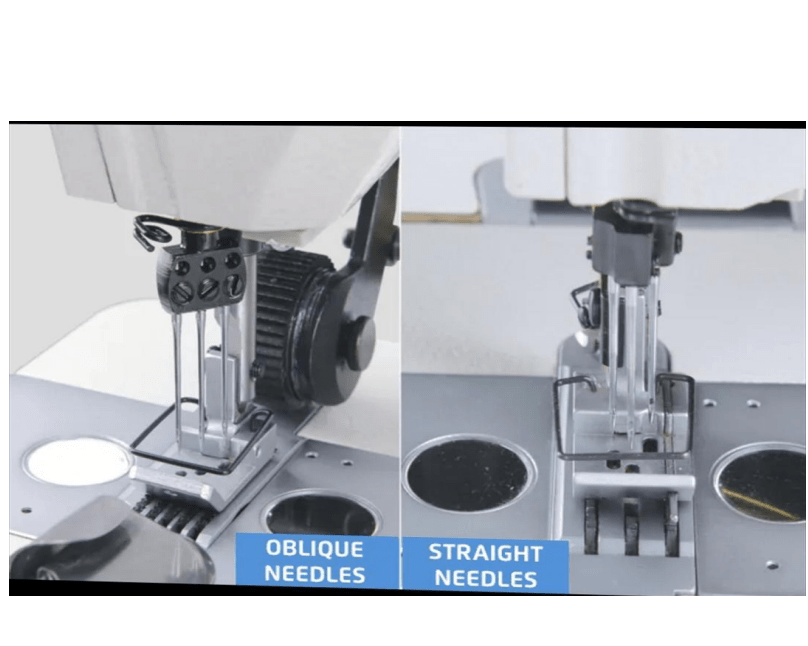

- Interlocking Sewing Machine

- Function: Used for complex stitching patterns and

decorative stitches, often found in industrial

applications.

Compatible Needle:

- Microtex Needles: Suitable for precise stitching on fine

fabrics, making them a good match for the intricate

stitching patterns produced by this machine.

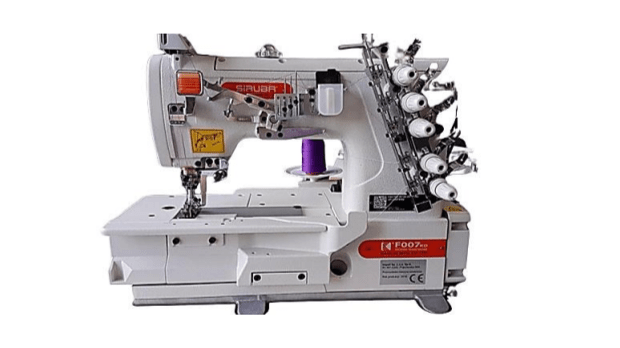

- Cover Stitch Sewing Machine

- Function: Creates professional-looking hems and

topstitching on knit fabrics, frequently used in garment

construction.

• Compatible Needle: Uses specific cover stitch needles.

Tapestry, Microtex, and Beading needles are not typically

used with this machine.

- Double Needle Sewing Machine

- Function: Utilizes two needles to create parallel rows

of stitching, commonly for hems and decorative finishes. - Compatible Needle: Twin needles are used for this

machine. Tapestry, Microtex, or Beading needles are not

suitable.

- Chain Stitch Sewing Machine

- Function: Produces a flexible, chain-like stitch, ideal

for seams that need to stretch, commonly used for knit

fabrics. - Compatible Needle: Chain stitch needles are used.

Tapestry, Microtex, and Beading needles are not

compatible.

- Domestic Embroidery Machine

- Function: Designed for creating intricate embroidery

patterns on a variety of fabrics.

Compatible Needle

- Microtex Needles: Suitable for detailed and precise

embroidery work, especially on fine fabrics. - Beading Needles: Can be used if the machine supports

beading functions to add beads and sequins to

embroidery projects. - Tapestry Needles: Generally used for hand embroidery,

but some specialized embroidery machines may

support their use. By matching the appropriate needle to the

corresponding sewing machine, you ensure smooth

• operation, high-quality stitching, and extended machine

and needle life.

Each needle type is designed to complement the

specific functions and capabilities of the sewing machine

it is used with, optimizing your sewing projects.

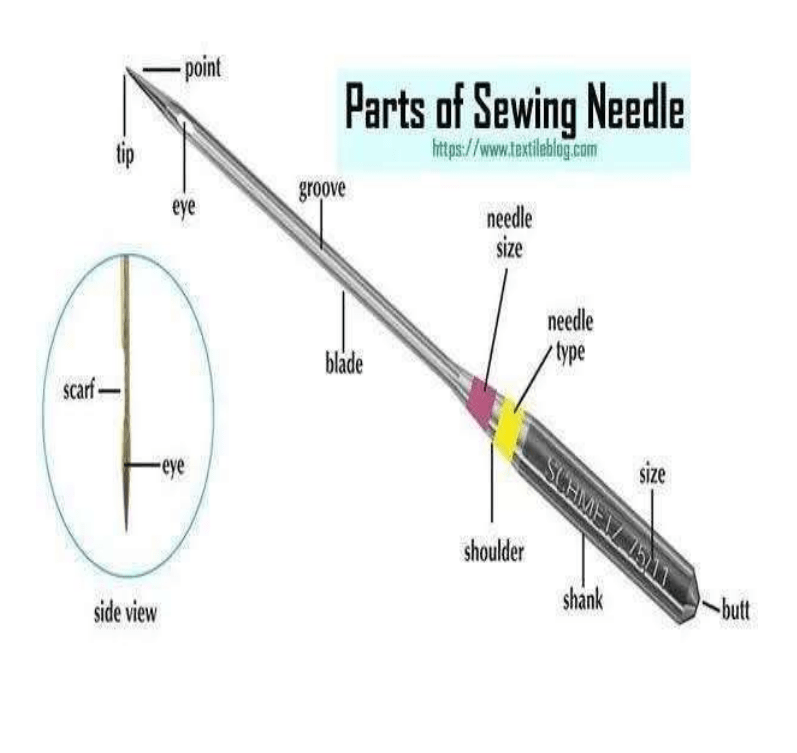

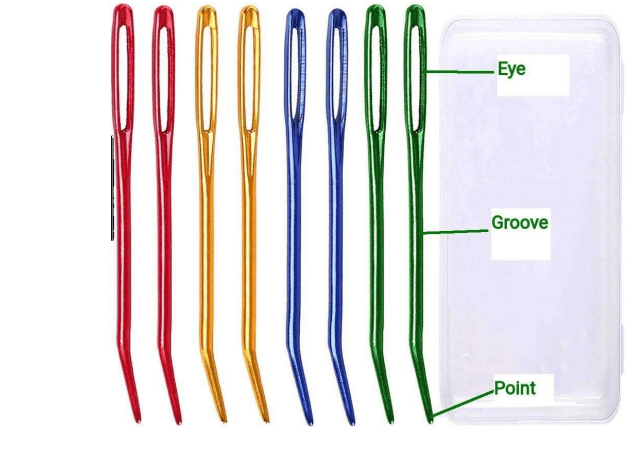

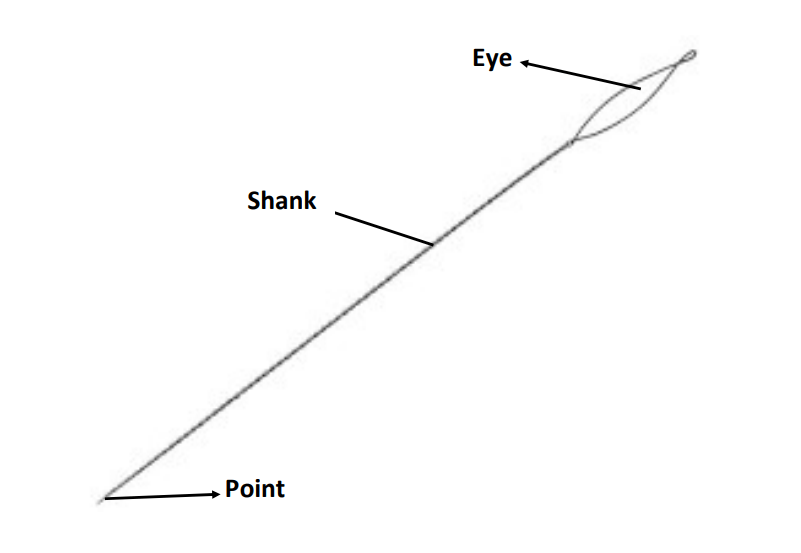

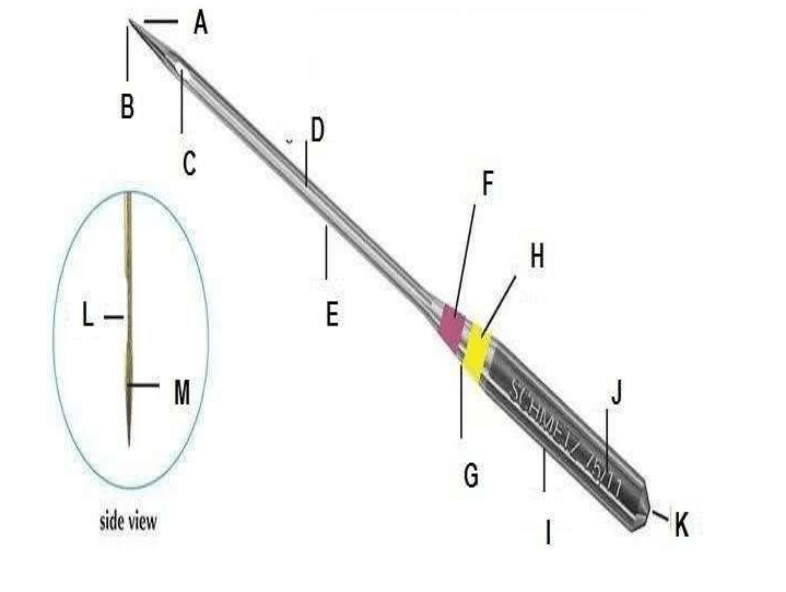

A Labelled Diagram with Explanation on the

Labelled Parts of Each Needle

To understand the structure and function of sewing

needles, it’s essential to examine their parts in which each

part of a needle plays a crucial role in its performance.

Below is a detailed explanation of the key parts of

Tapestry, Microtex, and Beading needles, accompanied

by a labelled diagram

Diagram:

Sewing Needle Diagram

- Shank

- Description: The upper part of the needle that is

inserted into the sewing machine, it is thicker than the rest

of the needle. - Function: Provides stability and ensures the needle is

properly aligned in the machine, for hand needles, this is

the part you hold while sewing.

- Eye

- Description: The hole near the pointed end of the

needle through which the thread passes. - Function: Holds the thread as the needle moves through

the fabric, in which the size and shape of the eye vary

depending on the needle type.

- Point

- Description: The tip of the needle that penetrates the

fabric. - Function: Designed to suit specific fabrics and stitching

techniques, its point can be sharp, blunt, or ballpoint.

- Groove

- Description: A channel on the front of the needle running

from the eye to the point. - Function: Protects the thread as it moves through the

fabric, reducing friction and preventing thread breakage.

- Scarf

- Description: An indentation above the eye on the

back side of the needle. - Function: Allows the bobbin hook to catch the thread

loop formed during stitching, ensuring a smooth

stitch formation.

Detailed Descriptions for Each Needle Type

1. Tapestry Needle

- Shank: Thick and robust, providing stability during hand

embroidery. - Shaft: Medium to thick, suitable for handling heavier

threads and yarns.

Eye: Large, accommodating thicker threads and yarns

easily.

- Point: Blunt, designed to pass through fabric without

splitting it, ideal for counted cross-stitch and needlepoint. - Groove: Standard, suitable for guiding thicker threads.

- Scarf: Minimal, as it is primarily a hand needle.

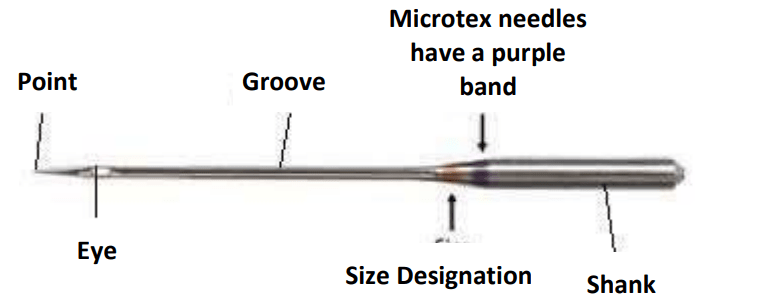

2. Microtex Needle

- Shank: Standard size for machine use.

- Shaft: Thin, allowing for precision in stitching fine

fabrics. - Eye: Small, accommodating finer threads.

- Point: Very sharp and slender, designed to pierce

through tightly woven fabrics cleanly. - Groove: Narrow, ensuring precise thread guidance.

- Scarf: Pronounced, aiding in smooth stitch formation by

the machine’s bobbin hook.

3. Beading Needle

- Shank: Thin and long, designed for both hand and

machine use. - Shaft: Very thin, flexible, and long to accommodate

multiple beads. - Eye: Small and narrow, suitable for fine threads that

pass through tiny beads. - Point: Sharp, allowing easy passage through fabric and

beads. - Groove: Fine, suitable for delicate threads.

- Scarf: Slight, if used in a machine, aiding in smooth

stitching.

Each Needle Specific Uses

Each type of needle—Tapestry, Microtex, and

Beading—serves unique purposes in sewing and embroidery.

Their specific designs cater to different fabrics,

threads, and stitching techniques, ensuring optimal

performance for various projects.

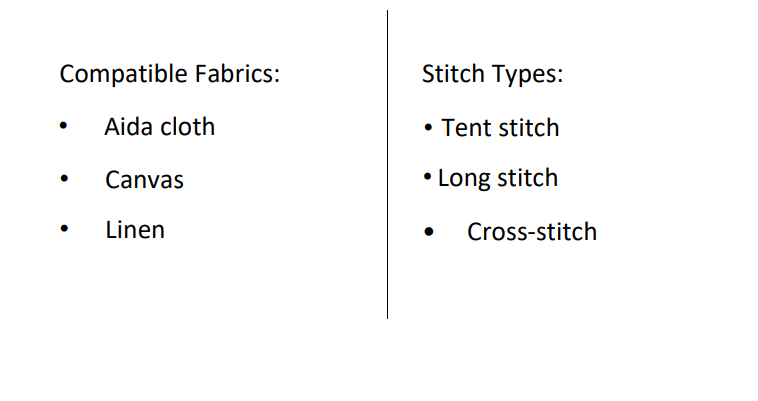

- Tapestry Needles

Uses:

Needlepoint: Tapestry needles are perfect for

needlepoint, where the blunt point prevents the splitting

of canvas threads, ensuring even stitches.

- Cross-Stitch: The large eye and blunt tip make tapestry

needles ideal for cross-stitch, as they glide through

prepunched holes in Aida fabric without damaging the

weave. - Embroidery on Heavy Fabrics: These needles work well

with thicker threads and yarns, suitable for embroidery on

heavy or loosely woven fabrics such as burlap.

- Microtex Needles

Uses:

- Precision Sewing: Microtex needles are ideal for

detailed, precise sewing on fine or tightly woven fabrics,

where a regular needle might cause puckering or

skipped stitches. - Silk and Microfiber: The sharp, slender point allows for

smooth sewing on delicate fabrics like silk and

microfiber without causing snags or runs. - Topstitching: Excellent for topstitching fine fabrics where

precise, clean lines are crucial.

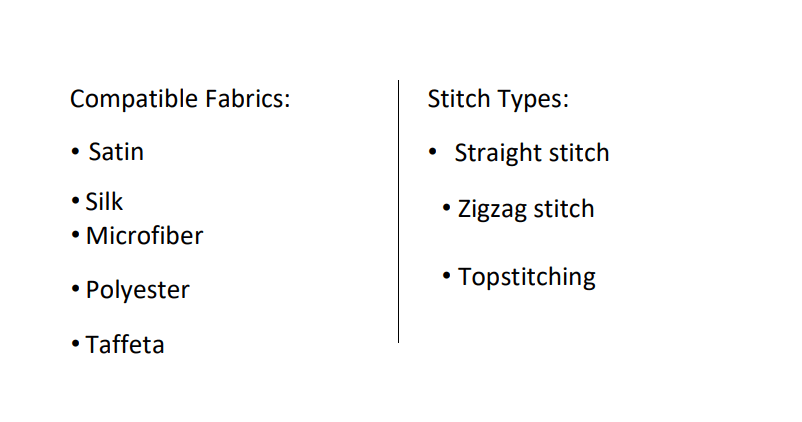

- Beading Needles

Uses:

- Bead Embroidery: Beading needles are designed to

easily thread through small beads, making them

perfect for intricate bead embroidery on fabrics. - Attaching Sequins: They are used to attach sequins and

other small embellishments to fabric, often in detailed

patterns or decorative designs. - Hand Beading: Ideal for hand sewing beads onto fabric

for embellishments, adding intricate details to

garments, accessories, and home decor items.

Compatible Fabrics:

• Tulle

- Lightweight fabrics

- Organza

- Sheer fabrics

Stitch Types: - Bead stitch

- Sequin stitch

- Couching stitch

Various Sizes of the Needle with Each

Application

Needles come in various sizes, which are crucial for

their specific applications.

The size of a needle affects how it interacts with

different fabrics and threads, influencing the quality of

the stitching, below are the typical sizes for Tapestry,

Microtex, and Beading needles and their corresponding

applications.

- Tapestry Needles

Sizes and Applications:

Size 18-22

- Application: Used for coarse fabrics like canvas and

burlap. - Thread Type: Suitable for thicker threads and yarns.

- Fabric: Ideal for needlepoint and other types of heavy

embroidery where the fabric weave is loose.

Size 24-26

- Application: Best for medium-weight fabrics like Aida

cloth. - Thread Type: Works well with embroidery floss and

medium-weight threads. - Fabric: Commonly used in cross-stitch and counted

thread embroidery. Size 28 - Application: Suitable for finer fabrics like linen.

- Thread Type: Used with fine embroidery threads.

- Fabric: Perfect for detailed cross-stitch and delicate

embroidery projects.

- Tapestry Needles

Sizes and Applications:

Size 18-22

- Application: Used for coarse fabrics like canvas and

burlap. - Thread Type: Suitable for thicker threads and yarns.

- Fabric: Ideal for needlepoint and other types of heavy

embroidery where the fabric weave is loose.

Size 24-26

- Application: Best for medium-weight fabrics like Aida

cloth. - Thread Type: Works well with embroidery floss and

medium-weight threads. - Fabric: Commonly used in cross-stitch and counted

thread embroidery. Size 28 - Application: Suitable for finer fabrics like linen.

- Thread Type: Used with fine embroidery threads.

- Fabric: Perfect for detailed cross-stitch and delicate

embroidery projects.

- Beading Needles

Sizes and Applications:

Size 10

- Application: Suitable for small beads and fine threads.

- Thread Type: Works with fine beading threads.

- Fabric: Used for delicate fabrics and detailed

beadwork. Size 11 - Application: A versatile size for various bead sizes.

- Thread Type: Compatible with medium beading

threads. - Fabric: Ideal for adding beads to medium-weight

fabrics.

Size 12

- Application: Best for very fine beadwork.

- Thread Type: Used with very fine threads.

- Fabric: Suitable for intricate bead embroidery on

delicate fabrics.

Size 13-15

- Application: For extremely fine and detailed beadwork.

- Thread Type: Pairs with ultra-fine threads.

- Fabric: Perfect for the finest fabrics and detailed bead

patterns. The correct needle size minimizes the risk of

damaging delicate fabrics and ensures that the thread

flows smoothly, resulting in professional-quality sewing

and embroidery.

Most Appropriate Needle for Various Machines

and the Reasons

Each needle type is designed to complement

specific machines and fabrics, here’s a detailed look at

which needles—Tapestry, Microtex, and Beading—are

best suited for various sewing machines and the reasons

why.

- 3 Thread Overlock Sewing Machine

Most Appropriate Needle:

- Not typically compatible with Tapestry, Microtex, or

Beading Needles. - Uses standard overlock needles.

- Reason: The overlock machine is designed for edge

finishing and seam construction, requiring robust

overlock needles to handle high-speed stitching and

fabric trimming.

- 4 Thread Overlock Sewing Machine

Most Appropriate Needle:

- Not typically compatible with Tapestry, Microtex, or

Beading Needles. - Uses specific overlock needles.

- Reason: Similar to the 3 thread overlock, it needs

sturdy needles for creating durable, stretchable seams,

especially on knit fabrics.

- 5 Thread Overlock Sewing Machine Most Appropriate

Needle:

- Not typically compatible with Tapestry, Microtex, or

Beading Needles. - Requires heavy-duty overlock needles.

Reason:

- This machine combines an overlock stitch and a chain

stitch, necessitating strong needles that can handle

multiple layers of fabric.

- Lock Stitch Sewing Machine

Most Appropriate Needle:

- Microtex Needles

Reason: - The lock stitch machine

is versatile, used for

straight stitching on a

variety of fabrics.

Microtex needles are

ideal for fine, tightly

woven fabrics, providing

precise, clean stitches

without damaging

delicate materials.

- Interlocking Sewing Machine Most Appropriate

Needle:

- Microtex Needles

Reason: - Interlocking machines

create complex stitching

patterns and decorative

stitches, microtex

needles, with their

sharp and slender

points, ensure precise - stitching on fine fabrics,

- enhancing the quality of

- decorative work.

- Cover Stitch Sewing Machine

Most Appropriate Needle:

- Not typically compatible with Tapestry, Microtex, or

Beading Needles. - Uses specific cover stitch needles.

Reason: - Cover stitch machines are used for hemming and

topstitching on knits, requiring specialized needles to

maintain stitch integrity and prevent skipped stitches.

- Double Needle Sewing Machine Most

Appropriate Needle:

- Not typically compatible with Tapestry, Microtex, or

Beading Needles. - Uses twin needles designed for the machine.

Reason: - This machine is for creating parallel rows of stitching.

Twin needles are essential for this task, providing

uniform spacing and tension for professional hems and

decorative stitching.

- Chain Stitch Sewing Machine

Most Appropriate Needle:

- Not typically compatible with Tapestry, Microtex, or

Beading Needles. - Requires chain stitch needles.

Reason: - Chain stitch machines are used for flexible seams on

knit fabrics, needing needles that can handle the

unique stitching mechanism of creating chain-like

loops.

- Domestic Embroidery

Machine Most Appropriate

Needle:

- Microtex Needles

- Beading Needles (if the machine supports beading

functions) - Tapestry Needles (in some specialized cases)

Reason: - Microtex Needles: Ideal for detailed and precise

embroidery work on fine fabrics, ensuring sharp, clean

stitches. - Beading Needles: Suitable for adding beads and

sequins, allowing for intricate decorative work if the

machine supports such features. - Tapestry Needles: Occasionally used in hand-guided

embroidery or specialized machines for heavy threads

and yarns.

Identification and Physical Observation of

These Needles

Identifying the correct needle type and

understanding its physical characteristics are essential

for effective sewing.

Below, we delve into the physical observation and

key identifiers of Tapestry, Microtex, and Beading

needles.

- Tapestry Needles

Identification:

- Shape: Tapestry needles are typically short and stout

compared to other needles. - Eye: They have a large, oval eye that can

accommodate thicker threads and yarns. - Point: The point is blunt, designed to pass through the

fabric without splitting the fibers.

Physical Characteristics:

- Size: They come in various sizes, typically ranging

from 18 to 28. The higher the number, the finer the

needle. - Material: Usually made from steel, nickel-plated for

smoothness and durability. - Surface: Smooth and polished to prevent thread

friction and ease penetration through fabric. - Flexibility: Slightly rigid to handle thicker threads

without bending easily.

- Microtex Needles

Identification:

Shape: Microtex needles are slender with a long, sharp

point.

- Eye: The eye is relatively small, designed to hold fine

threads securely. - Point: They have a very sharp, fine point for precise

piercing of fine or tightly woven fabrics.

Physical Characteristics:

- Size: Common sizes include 60/8, 70/10, 80/12, and

90/14. Lower numbers indicate finer needles. - Material: Made from high-quality steel, often coated

to reduce wear. - Surface: Ultra-smooth with a fine finish to ensure

minimal resistance through fabric. - Flexibility: Moderately flexible to avoid breaking while

maintaining strength for precision work.

- Beading Needles

Identification:

- Shape: Beading needles are long and very thin, often

the thinnest of all needle types. - Eye: The eye is small and narrow, barely wider than

the shaft to fit through small beads.

Point: The point is sharp to facilitate easy passage

through fabric and beads.

Physical Characteristics:

- Size: Sizes range from 10 to 15, with higher numbers

indicating thinner needles. - Material: Typically made from thin, flexible steel to

maneuver through beads. - Surface: Smooth and polished to prevent thread and

bead damage. - Flexibility: Highly flexible to bend without breaking,

suitable for intricate beadwork.

Identification and Use in Machines

Tapestry Needles:

- Hand Identification: Easy to identify by the blunt tip

and large eye. Best suited for hand embroidery. - Machine Use: Rarely used in machines; if used, it’s

typically in specialized embroidery machines for heavy

threads.

Microtex Needles:

Hand Identification: Recognized by their sharp, slender

point and small eye. Look for the fine point.

- Machine Use: Insert the needle with the flat side of

the shank facing the back. Ensure it’s the correct size for

the fabric being sewn.

Beading Needles: - Hand Identification: Notable for their length and

thinness, with a tiny eye. They are much longer and

more flexible than other needles. - Machine Use: Used in specific machines that support

beading functions. Ensure the needle is threaded

properly with fine thread and inserted correctly.

Practical Tips for Physical Observation

- Magnifying Glass: Use a magnifying glass to closely

inspect the needle’s eye, point, and shaft. This helps in

identifying the fine details. - Feel the Point: Gently feel the needle’s point with

your fingertip. A blunt tip indicates a tapestry needle, a –

sharp point a Microtex, and a very fine point a beading

needle. - Compare Sizes: Compare needles of different sizes

side by side. This visual comparison aids in

understanding the scale and appropriate usage. - Check Flexibility: Carefully bend the needle slightly

(do not break it). Tapestry needles are less flexible,

Microtex needles moderately so, and beading needles

the most flexible.

Maintenance and Safety Precautions of Each

Needle

Proper maintenance and safety precautions are

essential for the longevity and performance of Tapestry,

Microtex, and Beading needles.

- Tapestry Needles

Maintenance:

- Cleaning: Regularly wipe the needles with a soft, dry

cloth to remove any dust, lint, or oils. - Storage: Store needles in a needle case or a fabric-lined

container to prevent rust and keep them sharp, avoid

storing them in humid areas to prevent corrosion. - Inspection: Frequently inspect needles for any signs of

wear, bending, or dullness. Replace them if they show

any damage.

Safety Precautions:

- Handling: Handle with care to avoid accidental pricks.

Always point the needle away from your body and

others. - Usage: Ensure the needle is appropriate for the fabric

and thread to avoid breakage.

Disposal: Dispose of damaged or worn needles in a

designated needle disposal container or wrap them in a

piece of fabric before throwing them away to prevent

injuries.

Do’s and Don’ts:

- Do’s:

- Use a needle threader for easy threading.

- Store needles properly to keep them clean and sharp.

- Change needles frequently to ensure smooth stitching.

- Don’ts:

- Do not force the needle through thick fabric, as it may

bend or break.

Avoid using a rusty or bent needle, as it can damage the

fabric.

- Don’t leave needles loose on the sewing table to prevent

accidental injury.

Microtex Needles

Maintenance:

- Cleaning: Clean the needles with a lint-free cloth to

remove residues and fabric particles. - Storage: Keep needles in a dry, cool place. Use a

magnetic needle holder or a designated needle case. –

Inspection: Check for dullness, bends, or other damage

before use. Replace needles after 8-10 hours of sewing

or if any damage is detected

Safety Precautions:

Handling: Handle with care, especially given the

sharpness of the needle point. Always keep the needle

capped or stored safely when not in use.

- Usage: Use the appropriate needle size and type for

your fabric to prevent breakage and ensure smooth

sewing. - Disposal: Dispose of needles in a puncture-resistant

container to prevent injury.

Do’s and Don’ts:

- Do’s:

- Match the needle size to the fabric and thread for

optimal performance. - Replace needles frequently to maintain stitch quality.

- Use a needle threader to avoid damaging the eye of the

needle. - Don’ts:

- Do not use Microtex needles on heavy fabrics; they are

designed for fine and tightly woven fabrics. - Avoid using dull or bent needles, as they can cause

skipped stitches and fabric damage. - Do not sew over pins to prevent needle breakage.

Beading Needles

Maintenance:

- Cleaning: Wipe needles with a soft cloth to remove oils

and dirt, especially after working with beads. - Storage: Store in a needle case or pin cushion to avoid

bending and keep them protected from moisture. - Inspection: Regularly inspect for bends or breaks,

especially since these needles are very thin and prone to

damage. Replace as necessary.

Safety Precautions:

- Handling: Due to their thinness, handle beading needles

gently to avoid bending, always keep them in a secure

place when not in use. - Usage: Ensure the needle matches the size of the beads

and thread to prevent breakage. - Disposal: Dispose of damaged needles safely in a sharps

container or wrapped in fabric to prevent accidental

injury.

Do’s and Don’ts:

- Do’s:

- Use fine threads compatible with the needle and beads.

- Store needles properly to avoid bending or damage.

- Replace needles if they become bent or dull to ensure

smooth beadwork. - Don’ts:

- Do not force the needle through tight bead holes; use a

larger bead or a thinner needle if necessary. - Avoid using thick threads that can strain and break the

needle. - Don’t leave needles loose; always store them safely to

prevent accidents.

SUMMARY

This project provides an in-depth exploration of

specialized sewing needles, focusing on Tapestry,

Microtex, and Beading needles.

It covers their applications, compatibility with

sewing machines, maintenance requirements, and safety

precautions.

Beginning with an introduction emphasizing the

importance of needle selection in achieving precise

sewing results, the project defines each needle type and

outlines their specific uses.

Subsequent sections detail compatibility with

different sewing machines, labeled diagrams illustrating

needle parts, specific needle uses, sizes, and applications,

as well as recommendations for various machine types.

Additionally, the project discusses identifying and

observing needle characteristics, offering practical tips for

distinguishing between needle types.

Concluding with maintenance guidelines and safety

precautions, the project ensures proper care and usage of

these specialized needles.

Overall, this project serves as a comprehensive guide

for sewing enthusiasts and professionals, enhancing their

understanding and proficiency in utilizing specialized

sewing needles for optimal results.

Multiple Choice Questions

1. The component labeled A is known as _______________

a) Point

- b) Tip

- c) Eye

- d) Groove

2. The component labeled B is known as

- a) Point

- b) Tip

- c) Eye

- d) Groove

3. The component labeled C is known as

- a) Point

- b) Tip

- c) Eye

- d) Groove

- The component labeled D is known as

- a) Point

- b) Tip

- c) Eye

d) Groove

6. The component labeled E is known as

- a) Blade

- b) Needle size

- c) Shoulder

- d) Needle type

7. The component labeled F is known as

- a) Blade

- b) Needle size

– c) Shoulder

d) Needle type

8. The component labeled G is known as

- a) Blade

- b) Needle size

- c) Shoulder

- d) Needle type

9. The component labeled H is known as

__ a)

Blade

- b) Needle size

- c) Shoulder

- d) Needle type

- The component labeled I is known as __

- a) Shank

– b) Size

c) Butt

- d) Scarf

10. The component labeled J is known as __

- a) Shank

- b) Size

- c) Butt

- d) Scarf

11. The component labeled K is known as

- a) Shank

- b) Size

- c) Butt

d) Scarf

12. The component labeled L is known as __

– a) Shank

- b) Size

- c) Butt

- d) Scarf

13. What is the primary focus of the project on specialized

sewing needles?

A) Exploring different types of fabric

B) Analyzing sewing machine compatibility

C) Understanding various needle sizes

D) Enhancing precision and professionalism in sewing

14. Which needles are specifically highlighted in the

project?

A) Tapestry, Quilting, and Serger needles

B) Microtex, Beading, and Embroidery needles

C) Universal, Ballpoint, and Denim needles

D) Twin, Leather, and Metallic needles

- What is the purpose of the labeled diagrams included in

the project?

A) Identifying sewing machine brands

B) Explaining the parts of each needle type

C) Demonstrating fabric types

D) Highlighting stitching techniques - Which section of the project discusses the specific uses

of Tapestry, Microtex, and Beading needles?

A) Section E: Various Sizes of the Needle with Each

Application

B) Section F: Most Appropriate Needle for Various

Machines and the Reasons

C) Section G: Identification and Physical Observation

of These Needles

D) Section H: Maintenance and Safety Precautions of

Each Needle - According to the project, what contributes to selecting

the right needle size?

A) The color of the fabric

B) The texture of the thread

C) The type of sewing machine

D) The fabric and thread type

- Which needle is most appropriate for a Lock Stitch

Sewing Machine?

A) Tapestry Needle

B) Microtex Needle

C) Beading Needle

D) Universal Needle - What is the main purpose of identifying and observing

needle characteristics in the project?

A) To test needle durability

B) To distinguish between needle types

C) To compare needle prices

D) To select the most expensive needle

- According to the project, how should damaged needles

be disposed of?

A) Throw them in the trash

B) Bury them in the garden

C) Recycle them at a sewing store

D) Place them in a sharps container - What is the overall goal of the project on specialized

sewing needles?

A) To discourage people from sewing

B) To sell sewing machines

C) To provide a comprehensive guide for sewing

enthusiasts

D) To learn about different types of thread - Which needle is suitable for precision sewing on fine or

tightly woven fabrics? A) Tapestry Needle

B) Microtex Needle

C) Beading Needle

D) Universal Needle

- What role does the scarf play in a sewing needle? A) It

holds the thread securely.

B) It helps in identifying the needle size.

C) It guides the needle through the fabric.

D) It allows the bobbin hook to catch the thread loop. - Where can you find practical guidance on observing

needles for identification purposes?

A) The section discussing the most appropriate needle

for various machines

B) The section focusing on maintenance and safety

precautions of each needle

C) The summary section summarizing the entire

project

D) The section detailing the labelled parts of each

needle - Why is it important to match the appropriate needle to

the corresponding sewing machine?

A) To increase the cost of sewing projects

B) To ensure smooth operation and high-quality

stitching

C) To confuse sewing enthusiasts

D) To make sewing more difficult

- Understanding the different types of needles and their

specific _ is essential for achieving precise and

professional results. - This project focuses on three types of specialized

needles: __, Microtex, and Beading needles. - Sewing machines are designed for specific types of

stitching, each requiring particular needles to function

_. - The 3 Thread Overlock Sewing Machine is typically used

to finish the edges of fabric to prevent _.

–

- The 4 Thread Overlock Sewing Machine adds an

additional thread for increased _ and flexibility

in seams. - The 5 Thread Overlock Sewing Machine combines an

overlock stitch and a chain stitch for a secure and

__ seam. - Microtex needles are ideal for the Lock Stitch Sewing

Machine, especially for sewing fine or tightly woven

fabrics due to their sharp, __ point. - The Interlocking Sewing Machine is used for complex

stitching patterns and __ stitches. - The Cover Stitch Sewing Machine creates

professionallooking hems and _ on knit fabrics. - The Double Needle Sewing Machine utilizes two

needles to create parallel rows of stitching, commonly

for hems and _ finishes. - The Chain Stitch Sewing Machine produces a flexible,

chain-like stitch, ideal for seams that need to _.

- The Domestic Embroidery Machine is designed for

creating intricate _ patterns on a variety of

fabrics. - The Shank is the upper part of the needle that is

inserted into the sewing machine and provides

_. - The Eye is the hole near the pointed end of the needle

through which the _ passes. - The Point of the needle is designed to suit specific

fabrics and stitching _. - The Groove is a channel on the front of the needle

running from the eye to the _. - The Scarf is an indentation above the eye on the back

side of the needle that allows the bobbin hook to catch

the thread _. - Tapestry needles have a large eye, a blunt point, and

are ideal for counted cross-stitch and _.

- Microtex needles have a very sharp and slender point,

designed to pierce through tightly woven fabrics

_. - Beading needles are long and thin with a small eye,

suitable for threading through small _. - The correct needle size minimizes the risk of damaging

delicate fabrics and ensures that the thread flows

_, resulting in professional-quality sewing and

embroidery. - To identify a Tapestry Needle, look for its thick shank,

medium to thick shaft, large eye, and __ point. - Microtex needles are identified by their thin shaft,

small eye, and very __ point. - Beading needles can be identified by their thin, flexible

shaft and __ eye. - Proper maintenance of needles includes regular

cleaning, appropriate storage, frequent inspection, and

safe __.