19 minute read

introduction

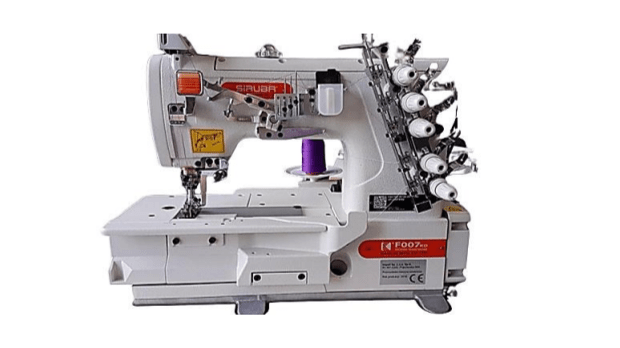

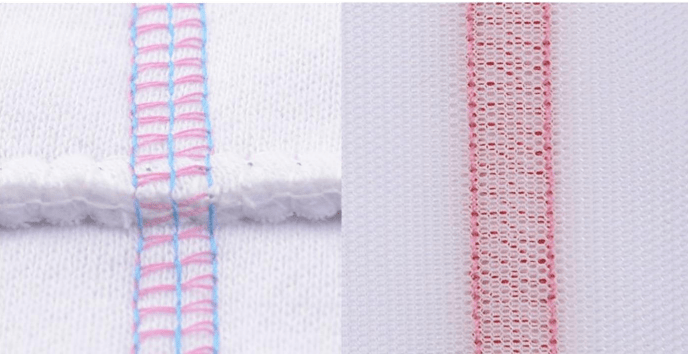

A cover stitch sewing machine is a type of industrial

sewing machine that uses two to five threads to

create a strong, stretchy stitch for sewing knit

fabrics, such as t-shirts, activewear, and swimwear.

It is designed to mimic the stitch of an

overlock machine, but with a cover stitch, the

threads form a loop on the underside of the fabric,

creating a flexible and comfortable seam.

The cover stitch sewing machine was

invented in the early 20th century as a response to

the growing demand for knit garments. The first

cover stitch machines were developed in the 1920s

and 1930s, with early versions using two threads

and later models introducing three and four

threads.

The modern cover stitch machine has evolved

to include computerized and automated features,

increasing efficiency and productivity in the textile

industry.

Key features:

1.Uses two to five threads: Cover stitch machines

can use two, three, four, or five threads,

depending on the specific model and the

desired stitch type.

2.Creates a strong, stretchy stitch : The cover

stitch is designed to be flexible and durable,

making it ideal for knit fabrics that require a bit

of give.

3.Suitable for knit fabrics: Cover stitch machines

are specifically designed for sewing knit fabrics,

such as cotton, polyester, and spandex blends.

4.Flexible and comfortable seam: The cover

stitch creates a seam that is comfortable

against the skin and allows for flexibility and

movement.

5.Mimics the stitch of an overlock machine: The

cover stitch machine produces a stitch that is

similar to an overlock machine, but with a few

key differences.

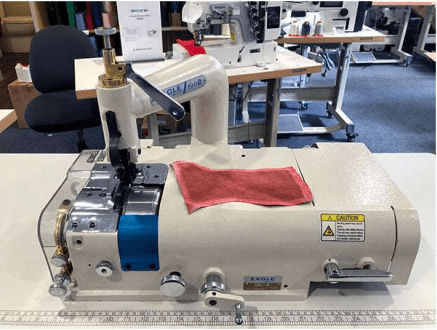

6.Industrial sewing machine: Cover stitch

machines are designed for heavy-duty use in

industrial settings, such as textile factories and

garment production lines.

Some additional features of modern cover stitch

machines include:- Automatic tension control:

Ensures consistent thread tension for a professional

finish.

–Adjustable stitch length and width: Allows for

customization of the stitch to suit specific fabric

types and garment styles.

High-speed sewing: Enables fast and efficient

production.

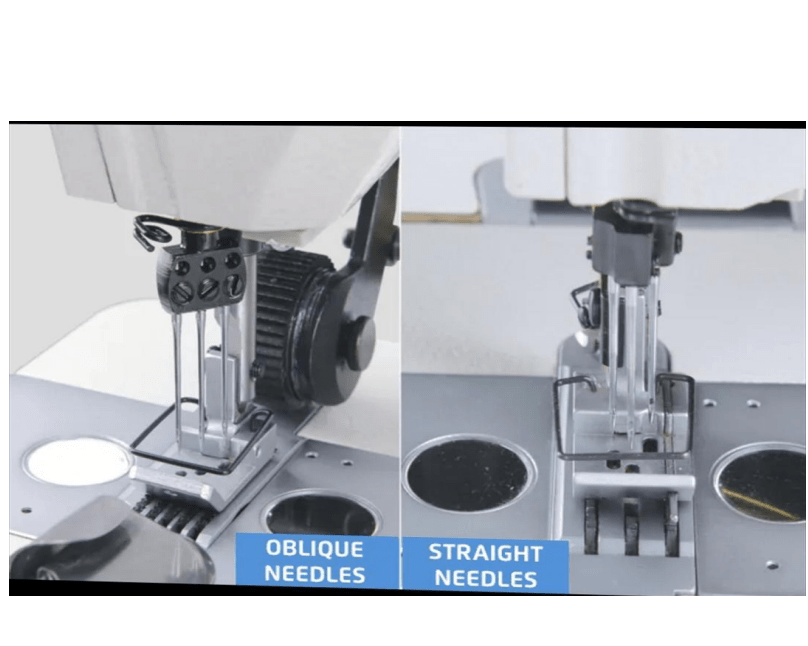

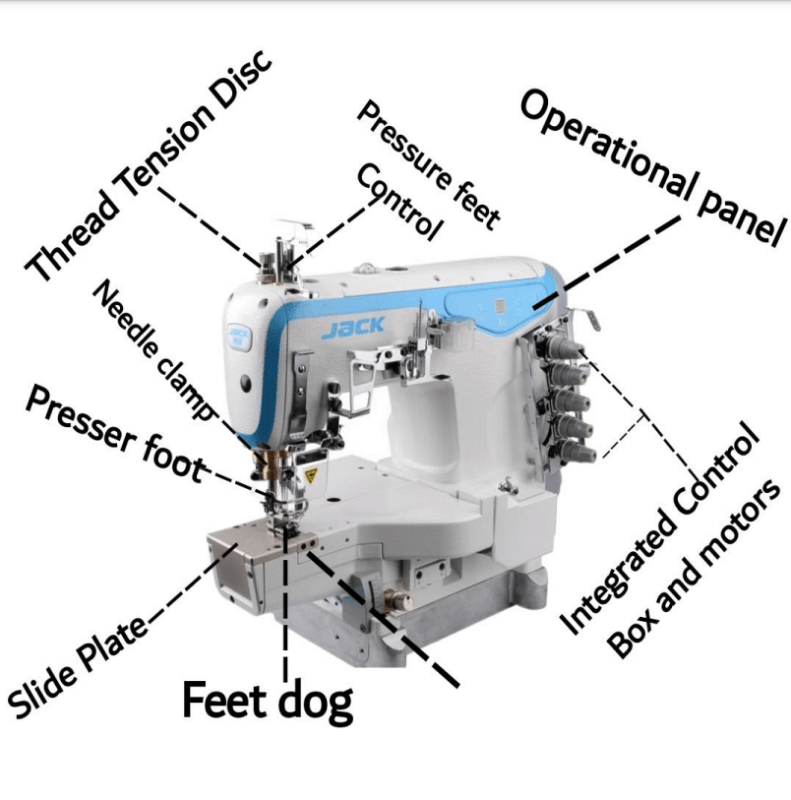

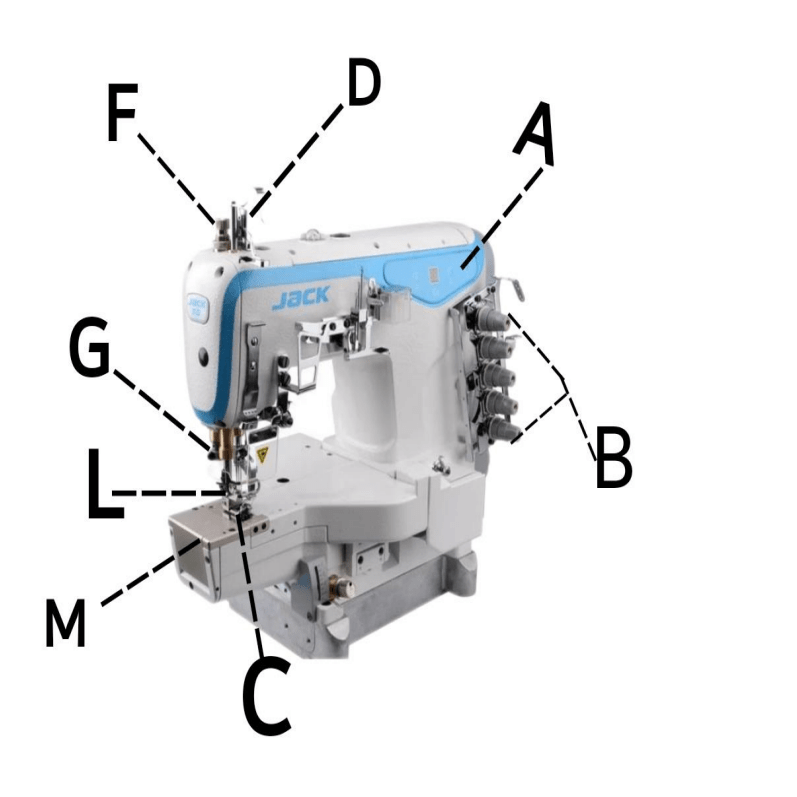

PARTS OF COVERSTITCH SEWING MACHINE

Functions of cover stitch sewing machine parts

1.Thread tension discs are small metal or plastic

discs that regulate the thread tension in a

cover stitch sewing machine, ensuring consistent

stitch quality and preventing thread tangling or

breakage

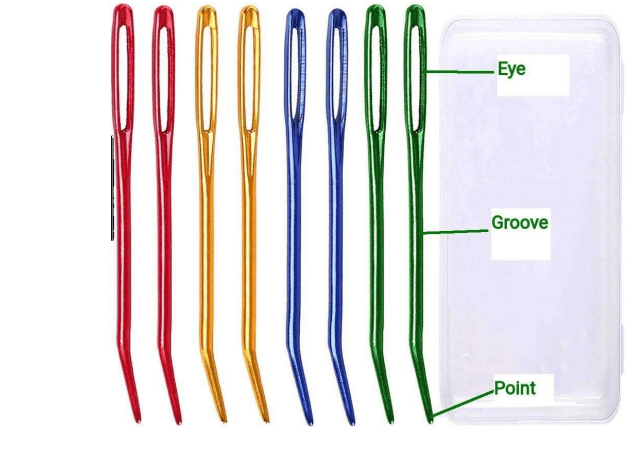

2.The needle clamp is a small metal or plastic

device that securely holds the needle in place on

the needle bar, preventing it from moving or falling

out during sewing, and ensuring consistent stitching

and preventing damage to the machine or fabric.

3.The slide plate is a removable metal plate that

covers the bobbin area and thread path, allowing

easy access for threading, bobbin replacement, and

maintenance, and can be slid open or removed to

expose the underlying mechanisms for cleaning and

troubleshooting.

4.The pressure foot, also known as the presser

foot, is a metal or plastic foot that applies pressure

to the fabric, holding it in place as it moves under

the needle, and allowing for smooth and even

stitching, with adjustable pressure to accommodate

various fabric thicknesses and types.

5.The feed dog is a small metal or plastic arm that

moves up and down in a circular motion, pulling the

fabric through the machine as you sew, and helping

to guide it smoothly under the needle, ensuring

consistent stitching and preventing fabric bunching

or dragging.

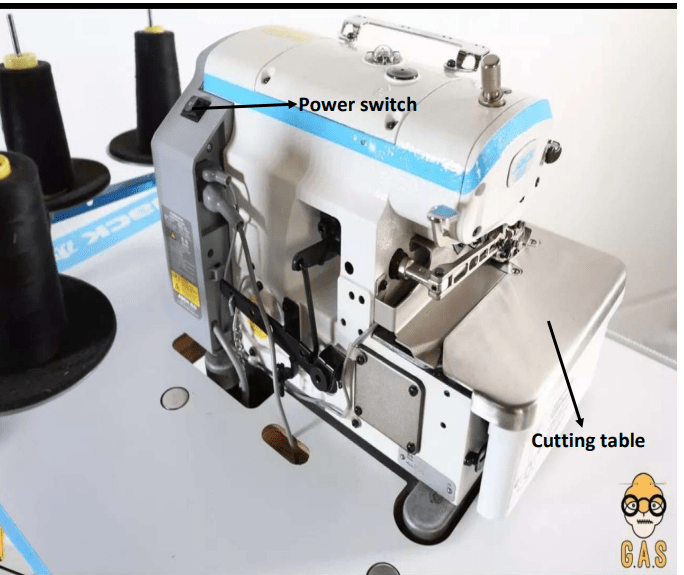

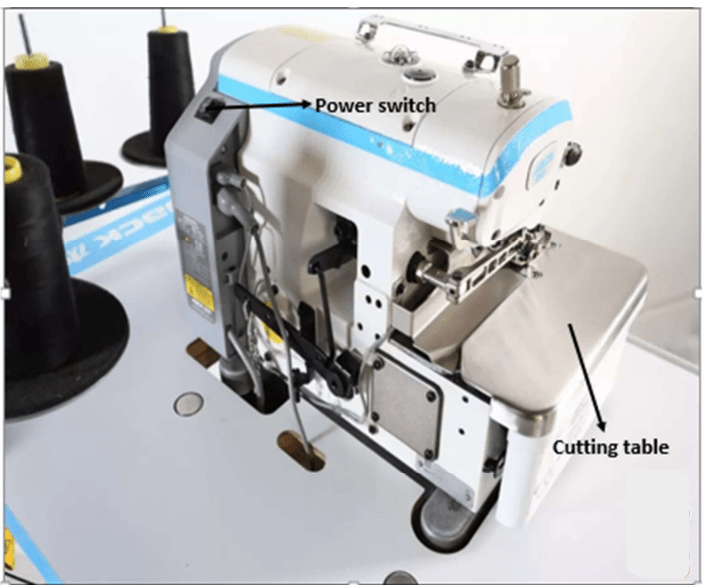

6.The operational panel is the control interface of

the cover stitch sewing machine, featuring buttons,

dials, and displays that allow the user to adjust

settings, select stitch options, and monitor the

machine’s status, providing an intuitive and user friendly experience for operating the machine and

customizing the sewing process.

7.The Integrated Control Box and motor is a

compact unit that combines the electronic controls

and motor of the cover stitch sewing machine,

managing the machine’s operations, such as stitch

length, thread tension, and speed, while also

powering the machine’s movements, providing a

efficient, quiet, and reliable sewing experience.

8.The pressure feet control is a mechanism that

allows you to adjust the pressure exerted by the

pressure feet on the fabric, enabling you to regulate

the amount of pressure applied to achieve

consistent stitching and seam quality.

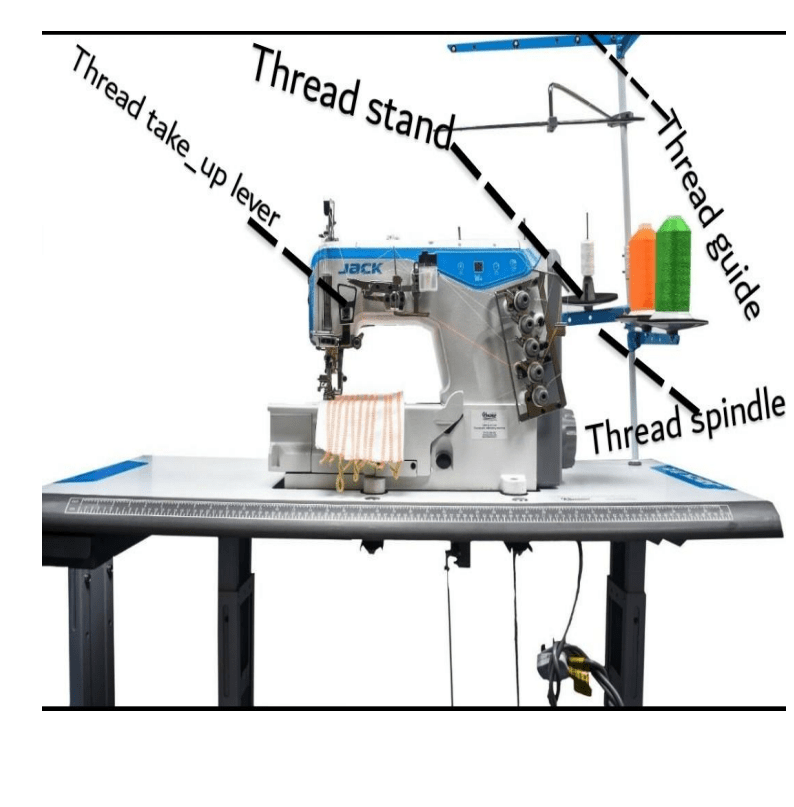

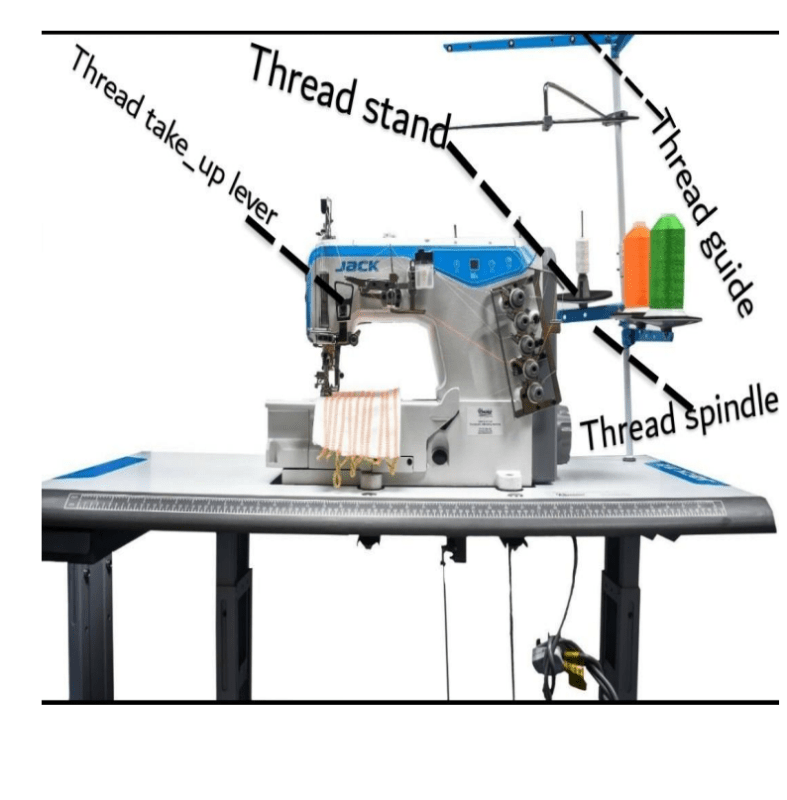

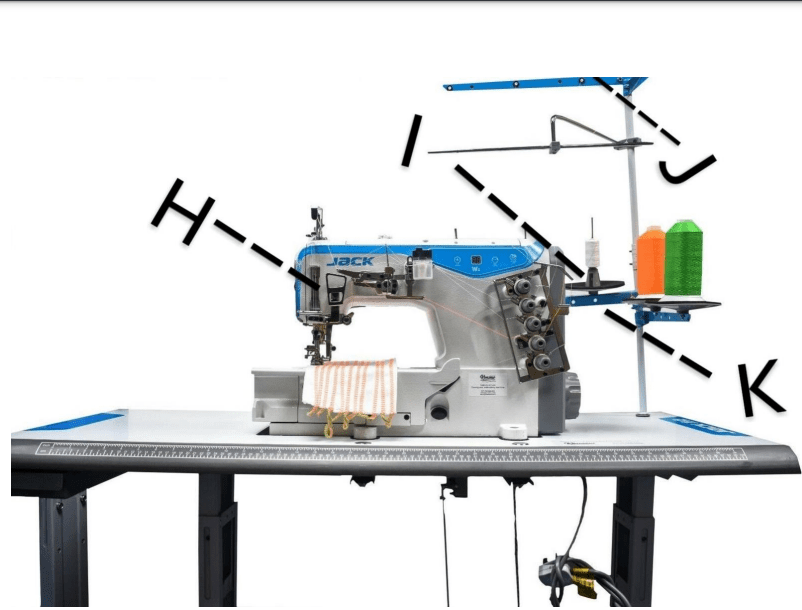

- The thread take-up lever is a metal arm that

moves up and down to pull the thread through the

machine, taking up the slack and maintaining the

correct thread tension, ensuring a consistent stitch

quality and preventing thread bunching or tangling.

It is typically located on the top of the machine,

near the spool pin, and is often controlled by a

spring or other mechanism to automatically adjust

the thread tension. - The thread guide is a small metal or plastic

component that directs the thread through the

sewing machine, keeping it on the correct path and

preventing tangles or knots.

11.A thread stand is a small device that holds the

thread spool upright and stable, keeping it

organized and within easy reach, and allowing for

smooth thread flow and tension control. It is usually

a small metal or plastic holder that can be attached

to the sewing machine or placed nearby, and is

designed to keep the thread spool from tangling or

falling over.

12.The thread spindle, also known as the spool pin

or thread pin, is a small metal or plastic rod that

holds the thread spool in place, allowing the thread

to unwind smoothly and evenly as it passes through

the sewing machine.

USES AND BENEFITS OF A COVERSTITCH SEWING

MACHINE

1.Professional hems: A cover stitch machine can

create a professional-looking hem on knit fabrics,

especially stretchy ones.

2.Topstitching: A cover stitch machine can be used

to add topstitching to activewear, such as leggings

or workout tops.

3.Attaching elastic or binding: A cover stitch

machine can be used to attach fabric or elastic

binding to swimwear, lingerie, or other garments in

a single step.

- Stretchy seams: A cover stitch machine can be

used to create stretchy seams on activewear, such

as workout pants or tops. - Decorative stitching : A cover stitch machine can

be used to create decorative stitching on garments,

such as a double or triple row of parallel stitching.

A cover stitch machine is a valuable addition to any

sewing room, especially for those who frequently

work with knit fabrics or activewear. It can help

create professional-looking hems, topstitching, and

seams, and can also be used for decorative

stitching.

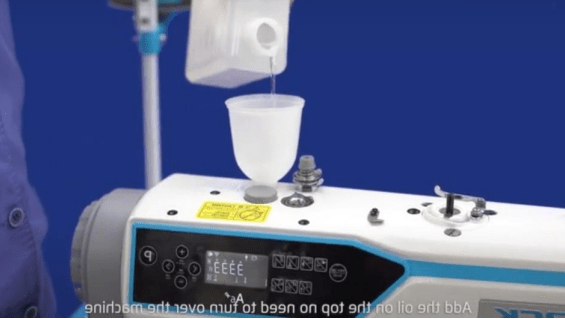

MAINTENANCE

Maintenance is crucial to extend the lifespan and

optimize the performance of a cover stitch sewing

machine. Here are some maintenance tips:

1.Regularly clean the machine: Use a soft brush

or cloth to remove lint, thread, and debris from

the machine’s interior and exterior.

2.Oil the machine: Apply a few drops of sewing

machine oil to the machine’s moving parts, such

as the needle bar, feed dog, and tension discs.

3.Check and adjust tension: Regularly check the

thread tension and adjust as needed to prevent

uneven stitching.

4.Replace needles and parts: Replace needles

and other parts as needed to maintain optimal

performance.

5.Use the correct thread: Use high-quality thread

suitable for knit fabrics and the cover stitch

machine.

6.Avoid overloading: Don’t overload the machine

with too much fabric or thread, as this can

cause damage.

7.Store the machine properly: Store the machine

in a dry, clean environment, and cover it with a

dust cover when not in use.

8.Perform regular servicing: Schedule regular

servicing with a professional technician to

ensure the machine is in good working

condition.

SAFETY MEASURES

safety measures to be considered when using a

cover stitch sewing machine:

1.Keep fingers away from the needle: Be mindful

of your fingers and keep them at a safe distance

from the needle to avoid accidents.

2.Use the correct needle size: Use the

recommended needle size for the fabric you’re

working with to prevent breakage and injury.

Prevent loose clothing and long hair from

getting caught in the machine.

3.Wear protective eyewear: Wear safety glasses

or goggles to protect your eyes from thread and

fabric debris.

4.Keep the work area clear: Keep the work area

clear of clutter and obstacles to prevent

tripping and falling.

5.Use the machine in a well-ventilated area:

Work in a well-ventilated area to prevent

inhaling thread and fabric dust.

6.Unplug the machine when not in use: Unplug

the machine when not in use to prevent

accidental start-ups.

7.Keep children and pets away: Keep children

and pets away from the machine to prevent

accidents.

8.Use the correct voltage: Use the correct voltage

recommended by the manufacturer to prevent

electrical shock.

9.Follow manufacturer’s instruction: follow the

manufacturer’s instructions and guidelines for

safe machine operation.

Questions

PART A

1)The components labeled as A is known as______________

A) Pressure foot

B) Needle clamp

C) Operational panel

D) Control box

2)The component labeled as B is known as____________

A) Operational panel

B) Integrated control box

C) Feet dog

D) Needle clamp

3) The component labeled as C is known as______________

A) Slide plate

B) Thread tension Dics

C) Feet dog

D) Throat plate

4)The component labeled as D is known as____________

A) Slide plate

B) Needle clamps

C) Feed dog

D) Pressure feet control

5)The component labeled as H is known as_____________

A) thread tension Disc

B) Integrated needdle

C) Spool pin

D) Thread take_up lever

6)The components labeled as J is also known as____________

A) Thread spindle

B) Thread guide

C) Thread take_up lever

D) Opening part

7)The components labeled K Is also known as___________

A) Thread stand

B) Thread guide

C) Thread take_up lever

D) Thread spindle

8)The component labeled as M is also known as____________

A) Slide plate

B) Pressure foot

C) Needle clamps

D) Cover stitch

9)The component labeled as G is also known as__________

A) Needle clamps

B) Pressure control

C) Operational plate

D) Spool pin

10) The component labeled as L is also known

as ___________

A) Pressure foot

B) Needle clamp

C) Slide plate

D) Thread spindle

11) The component labeled as F is also known

as _____________

A) Slide Plate

B) Needle xlamps

C) Integrated part

D) Thread tension discs

12) The components labeled as I is also known

as _____________

A) Operational panel

B) Dog slide

C) Slide plate

D) Thread stand

PARTS B

CHOOSE THE CORRECT ANSWER FROM QUESTIONS

1 – 12

13)What can a coverstitch machine be used for?

A) Only for sewing woven fabrics

B) Only for sewing knit fabrics

C) For creating professional-looking hems,

topstitching, and seams on knit fabrics

D) For embroidery only

14). What is a benefit of using a coverstitch

machine?

A) It can only be used for decorative stitching

B) It can create stretchy seams on activewear

C) It can only be used for sewing woven fabrics

D) It can only be used for sewing straight seams

15) What maintenance tip is crucial for extending

the lifespan of a coverstitch machine?

A) Regularly overload the machine with fabric and

thread

B) Never clean the machine

C) Regularly clean and oil the machine

D) Use low-quality thread

- Why is it important to check and adjust tension

on a coverstitch machine?

A) To prevent uneven stitching

B) To prevent breakage

C) To prevent overheating

D) To prevent rust - What safety measure should be taken when

using a coverstitch machine?

A) Keep fingers close to the needle

B) Wear loose clothing and long hair

C) Keep fingers away from the needle

D) Unplug the machine when in use

18What should be done with the machine when not

in use?

A) Leave it on

B) Store it in a humid environment

C) Store it in a dry, clean environment

D) Throw it away - Why is it important to use the correct thread

for a coverstitch machine?

A) To prevent breakage

B) To prevent uneven stitching

C) To prevent overheating

D) To prevent rust

20.What should be done with children and pets

when using a coverstitch machine?

A) Keep them close to the machine

B) Keep them away from the machine

C) Let them use the machine

D) Ignore them

21.What is a benefit of using a coverstitch machine

for topstitching?

A) It can only be used for decorative stitching

B) It can create stretchy seams on activewear

C) It can add a professional finish to garments

D) It can only be used for sewing straight seams - Why is regular servicing important for a

cover stitch machine?

A) To prevent breakage

B) To prevent uneven stitching

C) To ensure optimal performance

D) To prevent rust

D) None of the above

Parts C

Fill in the gap from 23 to 50

23)What type of industrial sewing machine is a

cover stitch sewing machine?

24.How many threads can a cover stitch sewing

machine use? ___________

25.What type of fabrics is a cover stitch sewing

machine suitable for? ___________

26.What is the main advantage of the stitch created

by a cover stitch machine?

27.Who is the target audience for cover stitch

machines? ___________

28.When was the cover stitch machine invented?

29.What was the driving force behind the

development of the cover stitch machine?

30.How many threads did early cover stitch

machines use? ___________

31.What is the name of the stitch produced by a

cover stitch machine?

32.How does the cover stitch machine mimic the

stitch of an overlock machine?

- What is the benefit of the flexible and

comfortable seam created by a cover stitch

machine? ___________ - What is the purpose of automatic tension

control in modern cover stitch machines?

- What is the advantage of adjustable stitch

length and width in modern cover stitch

machines? ___________ - How does high-speed sewing enable fast

and efficient production?

- What is the purpose of computerized

controls in modern cover stitch machines?

- How has the modern cover stitch machine

evolved from its early versions?

- What is the main difference between a

cover stitch machine and an overlock machine?

- What is the significance of the cover stitch

machine in the textile industry?

- What regulates thread tension in a

coverstitch sewing machine ____________ - What holds the needle in place in a

coverstitch sewing machine _____________ - What allows access for threading and

maintenance in a coverstitch sewing machine __________ - What applies pressure to fabric in a

coverstitch sewing machine___________ - What pulls fabric through the machine in a

coverstitch sewing machine __________ - What controls the machine’s operations in a

coverstitch sewing machine __________ - What powers the machine’s movements in

a coverstitch sewing machine __________ - What adjusts pressure on fabric in a

coverstitch sewing machine __________ - What takes up thread slack in a coverstitch

sewing machine –___________ - What guides thread through the machine in

a coverstitch sewing machine ____________

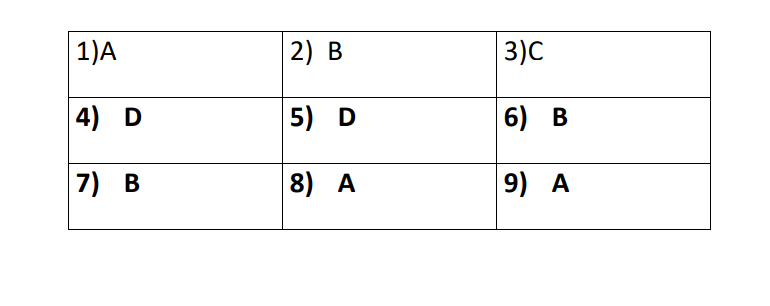

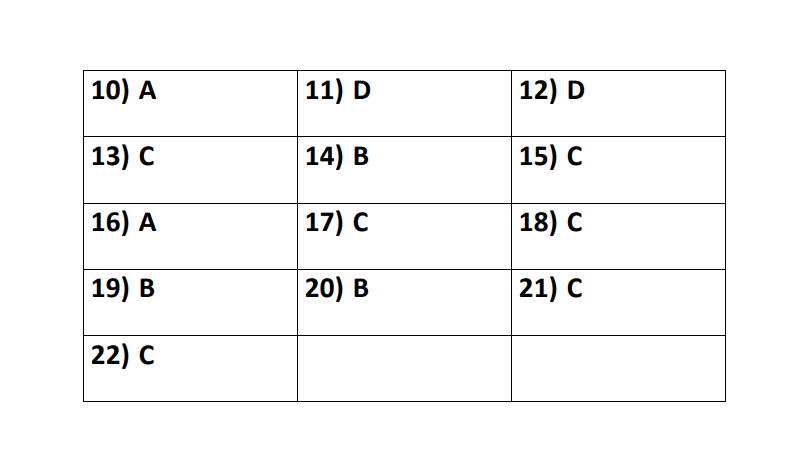

INSTRUCTORS COPY

ANSWERS TO MULTIPLE choice QUESTIONS

1_22

Answers to fill in the gap from 22 to 50

- Industrial sewing machine

- Two to five threads

- Knit fabrics

- Flexible and durable

- Textile industry

- Early 20th century

- Growing demand for knit garments

- Two or three threads

- Cover stitch

- Loop on the underside of the fabric

- Flexible and comfortable seam

- Consistent thread tension

- Customization of stitch

- Fast and efficient production

- Simplifies sewing process

- Computerized and automated features

- Type of stitch and number of threads

- Efficient and productive sewing of knit

fabrics - Thread discs

- Needle clamp

- Slide plate

- Pressure foot

- Feed dog

- Operational panel

- Integrated motor

- Pressure control

- Thread take-up

- Thread guide